Precoated films with UV protection

An anti-ultraviolet and anti-ultraviolet agent technology, applied in the direction of film/sheet adhesive, adhesive type, layered products, etc., can solve the problem of high production cost, high production equipment requirements, no UV protection function, etc. problem, to achieve the effect of simple structure and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

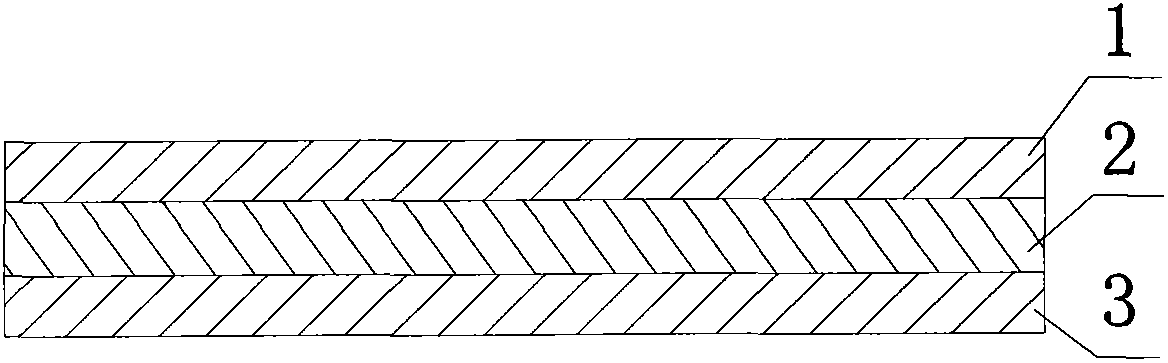

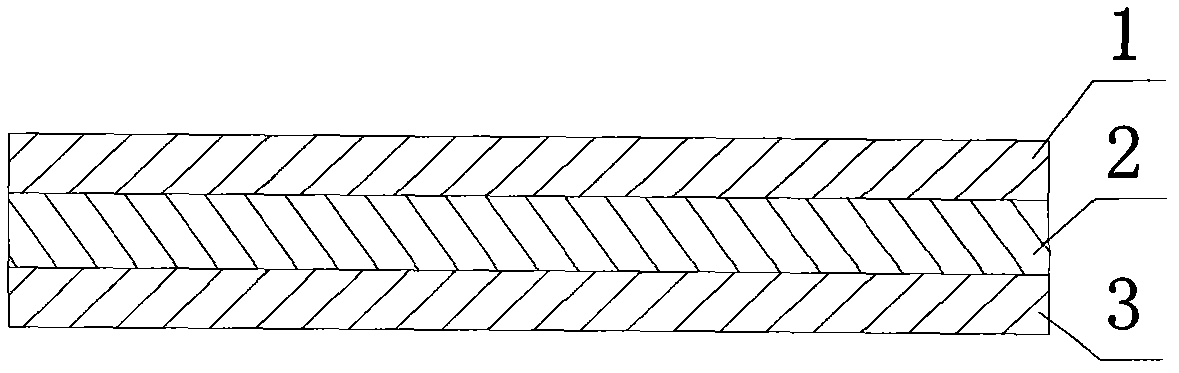

[0009] Such as figure 1 As shown, the pre-coated film with anti-ultraviolet function is composed of a secondary functional layer 1, a core layer 2, and a coating functional layer 3. The core layer 2 is located between the secondary functional layer 1 and the coating functional layer 3; the secondary functional layer The material of 1 is composed of polypropylene (PP) and anti-ultraviolet agent, and the addition of anti-ultraviolet agent is 0.1-3% of the mass of polypropylene; the material of core layer 2 is modified polyethylene (PE), and the functional layer is coated The material of 3 is an adhesive; the secondary functional layer 1, the core layer 2, and the coating functional layer 3 are heat-synthesized as one (feeding into an extruding compound machine for extrusion and heat-synthesizing, and the heat-sealing temperature is 85-120° C.).

[0010] The function of the secondary functional layer 1 is the appearance of the film and anti-ultraviolet rays. By adding additives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com