Anti-ultraviolet softening agent for wool fabric and preparation method of anti-ultraviolet softening agent

An anti-ultraviolet and softener technology, applied in the direction of animal fibers, textiles, papermaking, wear-resistant fibers, etc., can solve the problem that wool fabrics are easy to feel and shrink, and it is difficult to meet the soft and comfortable requirements of wool clothing, and the softness and hydrophilicity of wool fabrics In order to achieve the effect of good softness, smooth hand feeling and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

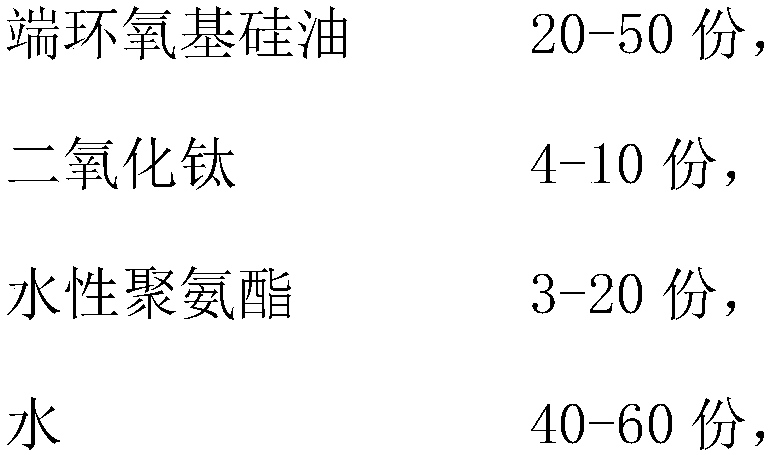

[0021] An anti-ultraviolet softening agent for wool fabrics, consisting of the following raw materials in parts by weight:

[0022]

[0023]

[0024] A preparation method of an anti-ultraviolet softener for wool fabrics, comprising the following steps:

[0025] (1) Preparation of titanium dioxide emulsion: stir titanium dioxide, triethanolamine and water with a particle size of 50 nm, then ultrasonically mix for 60 minutes, then add a coupling agent and stir evenly, to obtain the titanium dioxide emulsion;

[0026] (2) Loading of titanium dioxide: mix the above-mentioned titanium dioxide emulsion and epoxy-terminated silicone oil, and stir at a speed of 1800r / min for 1h to obtain the softener;

[0027] (3) Preparation of flexibilizer: Add titanium dioxide-modified epoxy-based silicone oil into absolute ethanol and stir evenly, add water-based polyurethane dropwise at a stirring speed of 50r / min, heat up to 80°C and stir for 20min after the dropwise addition is completed,...

Embodiment 2

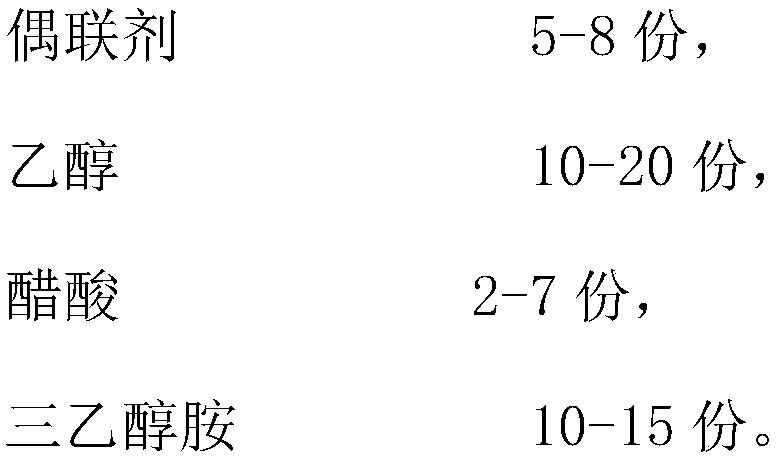

[0029] An anti-ultraviolet softening agent for wool fabrics, consisting of the following raw materials in parts by weight:

[0030]

[0031]

[0032] A preparation method of an anti-ultraviolet softener for wool fabrics, comprising the following steps:

[0033] (1) Preparation of titanium dioxide emulsion: stir titanium dioxide, triethanolamine and water with a particle size of 5 nm, then ultrasonically mix for 25 minutes, then add a coupling agent and stir evenly, to obtain the titanium dioxide emulsion;

[0034] (2) Loading of titanium dioxide: mix the above-mentioned titanium dioxide emulsion and epoxy-terminated silicone oil, and stir for 3 hours at a speed of 1000 r / min to obtain the softener;

[0035] (3) Preparation of flexibilizer: Add titanium dioxide-modified epoxy-based silicone oil into absolute ethanol and stir evenly, add water-based polyurethane dropwise at a stirring speed of 10r / min, heat up to 50°C and stir for 40min after the dropwise addition is compl...

Embodiment 3

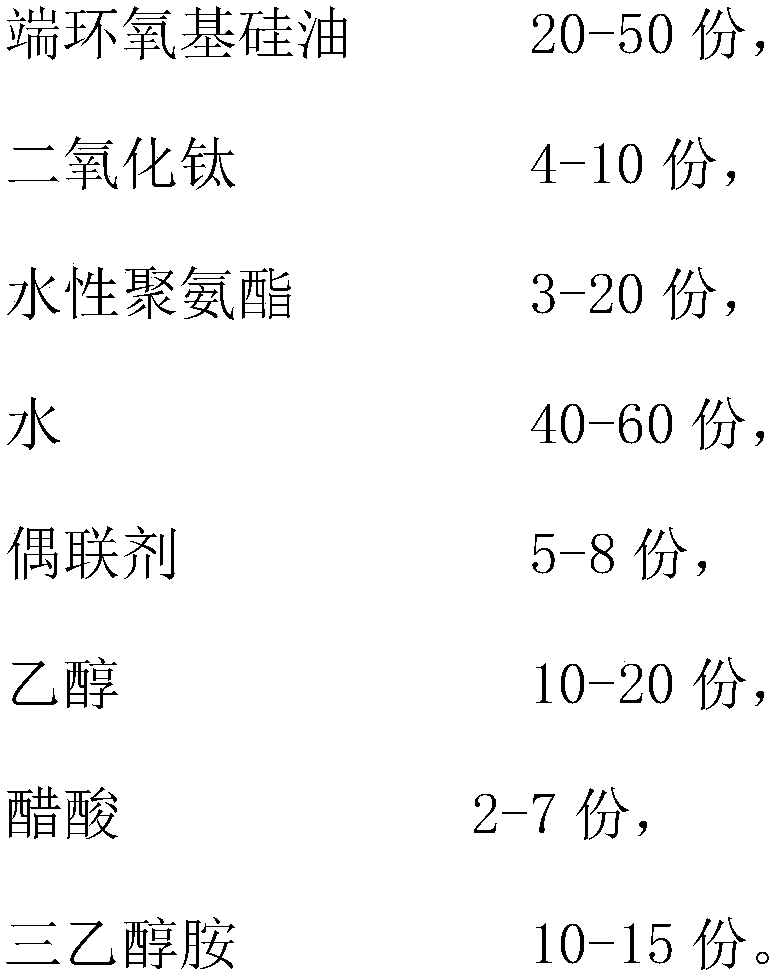

[0037] An anti-ultraviolet softening agent for wool fabrics, consisting of the following raw materials in parts by weight:

[0038]

[0039]

[0040] A preparation method of an anti-ultraviolet softener for wool fabrics, comprising the following steps:

[0041] (1) Preparation of titanium dioxide emulsion: Stir titanium dioxide, triethanolamine and water with a particle size of 20nm first, then ultrasonically mix for 30 minutes, then add a coupling agent and stir evenly to obtain the titanium dioxide emulsion;

[0042] (2) Loading of titanium dioxide: mix the above-mentioned titanium dioxide emulsion and epoxy-terminated silicone oil, and stir at a speed of 1300r / min for 2h to obtain the softener;

[0043] (3) Preparation of flexibilizer: Add titanium dioxide-modified epoxy-based silicone oil into absolute ethanol and stir evenly, add water-based polyurethane dropwise at a stirring speed of 40r / min, raise the temperature to 65°C and stir for 25min after the addition is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com