A treatment method for recovering nickel in nickel-containing waste liquid

A treatment method and technology for nickel waste liquid, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as environmental pollution, nickel cannot be effectively recovered, and achieve the speed of analysis Fast, simple operation, high nickel yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

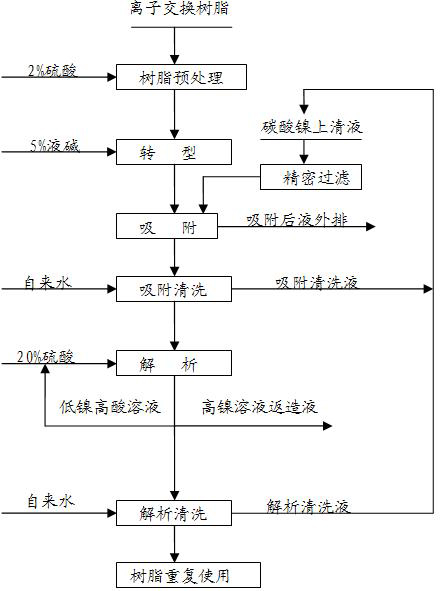

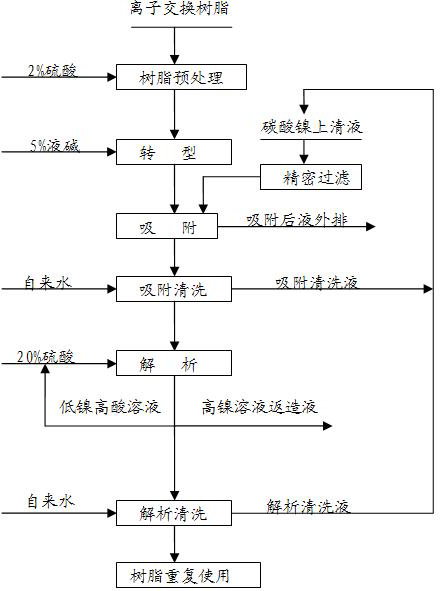

Method used

Image

Examples

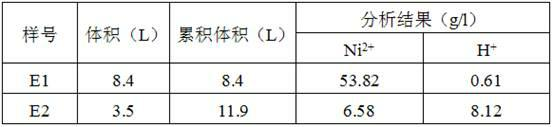

Embodiment 1

[0019] An ion-exchange column with a specification of Φ=100mm and L=1340mm is used, and 8.3L of resin is loaded inside; 2 SO 4 After pretreatment and transformation with NaOH solution with a mass percentage concentration of 5%, the nickel in the waste liquid of the nickel production system is adsorbed and recovered. The nickel content in the stock solution is about 0.02g / L, pH=7.8, temperature 65~70°C, adsorption flow rate 50L / h, nickel content in the solution after adsorption is ≤0.002g / l, and then 20% H 2 SO 4 Analysis, the concentration of liquid nickel after analysis and enrichment is 53.82 g / l, and the volume is 8.4L. The main data related to the resin adsorption and analysis process are shown in Table 1 and Table 2, respectively.

[0020] Table 1 Data sheet of resin adsorption process

[0021] serial number Sample number Volume (L) Cumulative volume (L) cumulative volume (BV) Analysis result (g / l) Supernatant (g / l) 1 L1 400 400 48.2 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com