A joint structure with decoupling effect

A joint structure and function technology, applied in the direction of pipes/pipe joints/pipe fittings, noise reduction devices, engine components, etc., can solve the problem of high price of bellows, achieve the effect of solving vibration problems, significant cost advantages, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

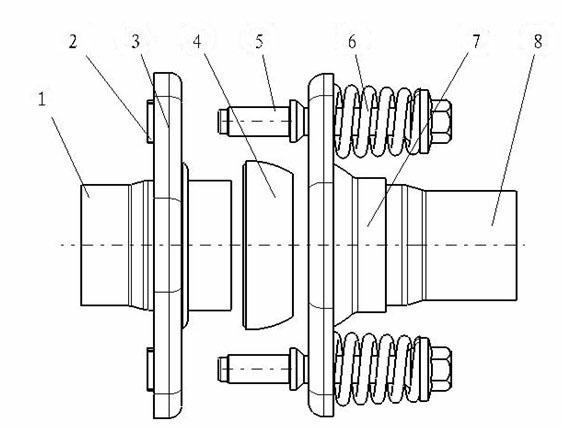

[0021] see figure 1 : This joint structure includes plane flange 3, spherical concave flange 7, sealing ring 4, compression spring 6, bolt 5 and nut 2, etc. The flat flange 3 and the pipeline or device 1 at the front end are connected together by welding, and the pipeline or device 1 extends out of the flat flange 3 for a small section. The nut 2 is welded on the flat flange 3 for easy assembly. The spherical concave flange 7 is connected with the pipeline or device 8 at the rear end by welding, and the side of the sealing ring 4 facing the spherical concave flange 7 is a spherical surface, and the spherical part cooperates with the spherical concave surface of the spherical concave flange 7 to form a sealing surface.

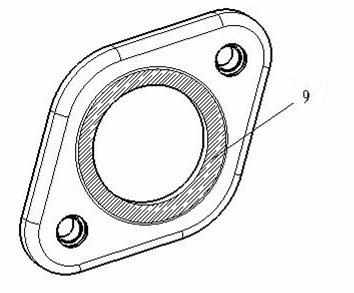

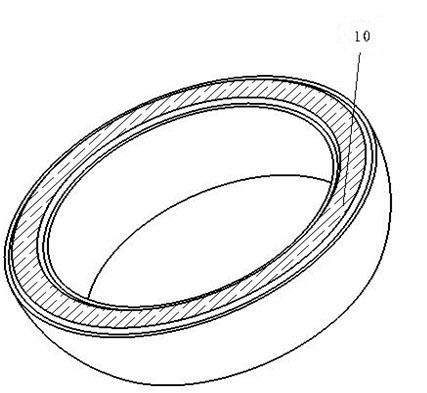

[0022] see figure 2 and image 3 , There is a ring of sealing ring bosses 10 on the side of the sealing ring 4 facing the flat flange 3, and a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com