Appraisal platform and method for mechanical seals of reactor coolant pumps in mega-kilowatt nuclear power plants

A nuclear power plant reactor, mechanical seal technology, applied in mechanical equipment, liquid variable capacity machinery, pump testing and other directions, to achieve the effect of saving costs, facilitating safe production, and improving the ability of fault diagnosis and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

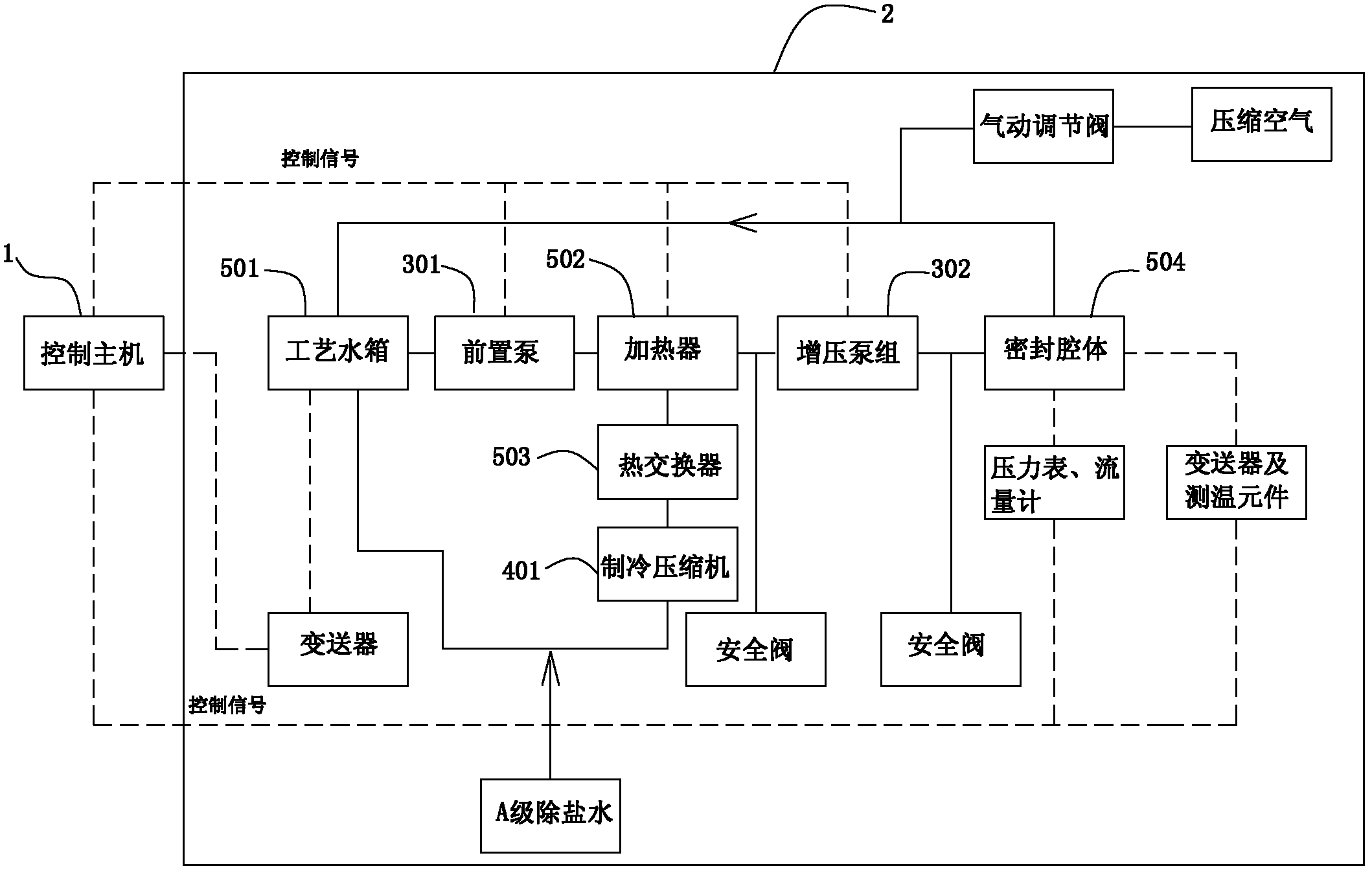

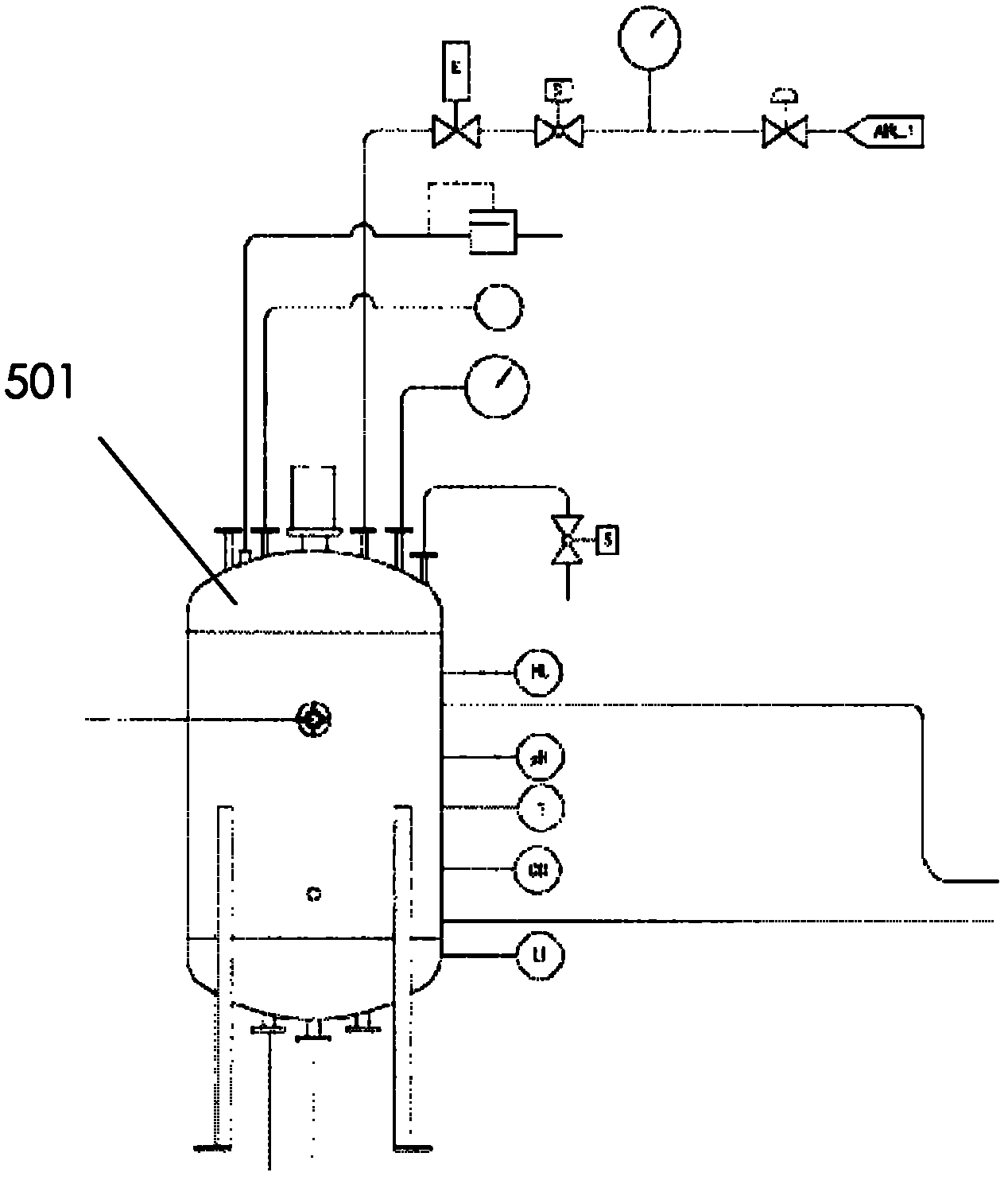

[0053] figure 1 It is a block diagram of the identification platform, where the dotted line is the transmission path of the control signal, and the solid line is the flow path of the circulating water. This embodiment 1 is mainly applied to the functional appraisal of the 8-inch No. 1 seal of the CPR1000 main pump.

[0054] The main pump mechanical seal appraisal platform includes a seal appraisal test bench 2 and a control host 1 for controlling the seal appraisal test bench. The control host 1 is used to control various test parameters of the seal qualification test bench 2. The sending of the control signal is realized by the software installed in the control host 1. These software mainly include the mechanical seal refurbishment program, mechanical seal test program, and mechanical seal inspection. Standard procedures and test acceptance criteria procedures, all control is realized through the human-computer interaction interface of the control host 1, without the need fo...

Embodiment 2

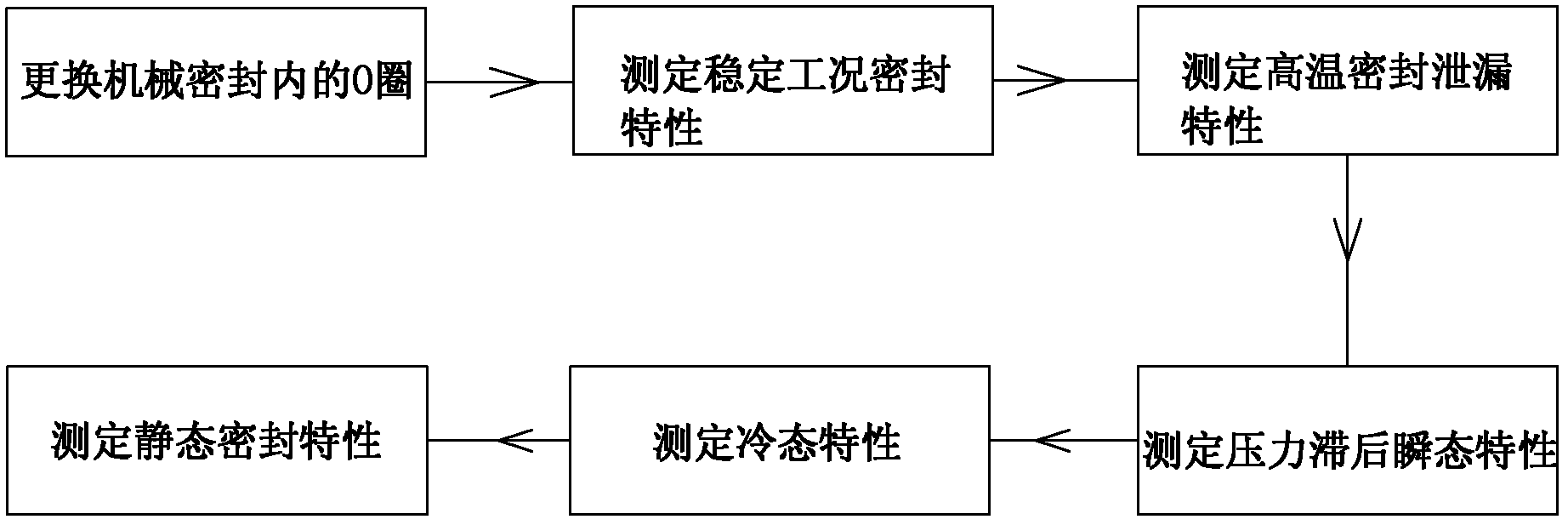

[0064] A method for identifying the mechanical seal of a reactor coolant pump in a million-kilowatt nuclear power plant, using the identification platform of Embodiment 1, comprising the following steps:

[0065] 1) Replace the static O-ring in the mechanical seal

[0066] Before appraising the mechanical seal, it is necessary to replace the aging static O-ring in the mechanical seal, and then appraise the mechanical seal after replacing the static O-ring.

[0067] 2) Determination of sealing characteristics in stable working conditions

[0068] Include the following sub-steps:

[0069] 2.1), input the pressure difference and temperature parameters under stable working conditions on the control host 1;

[0070] 2.2) Record the leakage of the mechanical seal under the pressure difference and temperature parameters of the above stable working conditions.

[0071] 3) Determination of high temperature sealing leakage characteristics

[0072] Include the following sub-steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com