an engine shock absorber

A shock absorber and engine technology, which is applied in the direction of spring/shock absorber, mechanical equipment, vibration suppression adjustment, etc., can solve the problems of weakened engine parts, hindering the work of surrounding instruments and equipment, and operator fatigue, etc., and achieve improvement Comfort, overcoming strength weakening, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

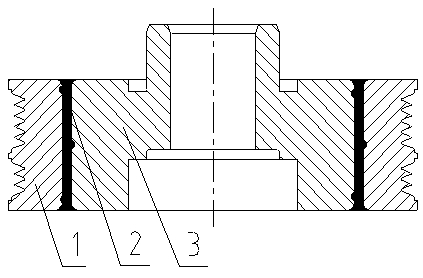

[0015] figure 1 Among them, the present invention consists of an outer ring 1, a rubber part 2 and a connecting part 3. The connecting piece 3 has a spiral circular groove, and the outer ring 1 has a spiral circular groove in the opposite direction. The rubber part 2 is located between the outer ring 1 and the connecting piece 3 . Belt grooves can be set on the outer ring 1 as required. The direction of rotation of the helical circular grooves on the connecting piece, the outer ring, must be opposite.

[0016] The rubber part 2 is molded by vulcanization, and the rubber part 2 is embedded between the outer ring 1 and the connecting part 3 by a press-fitting process.

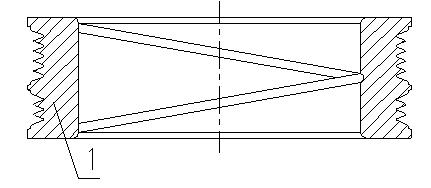

[0017] figure 2 Among them, a helical circular groove is provided on the inner peripheral surface of the outer ring 1 .

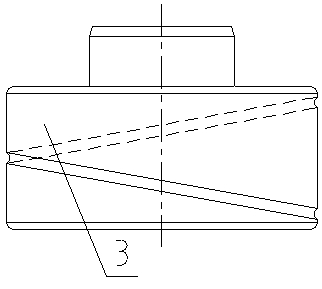

[0018] image 3 Among them, a helical circular groove is provided on the outer peripheral surface of the connector 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com