vehicle transmission

A transmission and transmission oil technology, applied in the direction of couplings, clutches, fluid-driven clutches, etc., can solve problems such as complex shifting processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

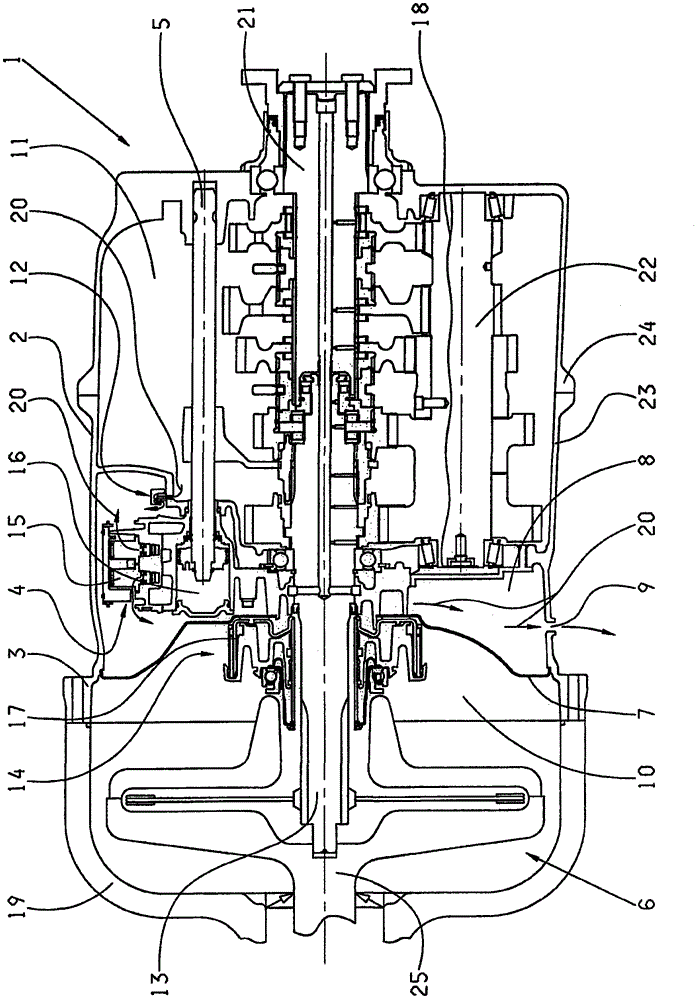

[0020] The vehicle transmission 1 shown comprises a transmission housing 2 which in this example is assembled from two housing parts, namely a drive-side housing half 23 and a rear output-side housing half 24 . On the drive side, the drive-side housing half shell 23 merges into the clutch bell 3 , wherein the clutch bell 3 is embodied in one piece with the drive-side housing half 23 . In a next step, the clutch housing 19 is connected to the clutch bell 3 on the drive side. The clutch housing 19 is screwed, for example, to the clutch bell 3 . Arranged in the clutch housing 19 are the basic components of the starter clutch 6 embodied as a multi-disk clutch.

[0021] The starter clutch 6 can be driven on the drive side via a drive shaft 25 by a drive motor (not shown). The drive torque is conducted via the transmission input shaft 13 into the vehicle transmission 1 by the starter clutch 6 . In the vehicle transmission 1 , the drive torque is directed to the transmission outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com