Constant force intraocular lens injector

A technology of intraocular lens and resistance, applied in the direction of syringes, intraocular lenses, and medical equipment, can solve troubles and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

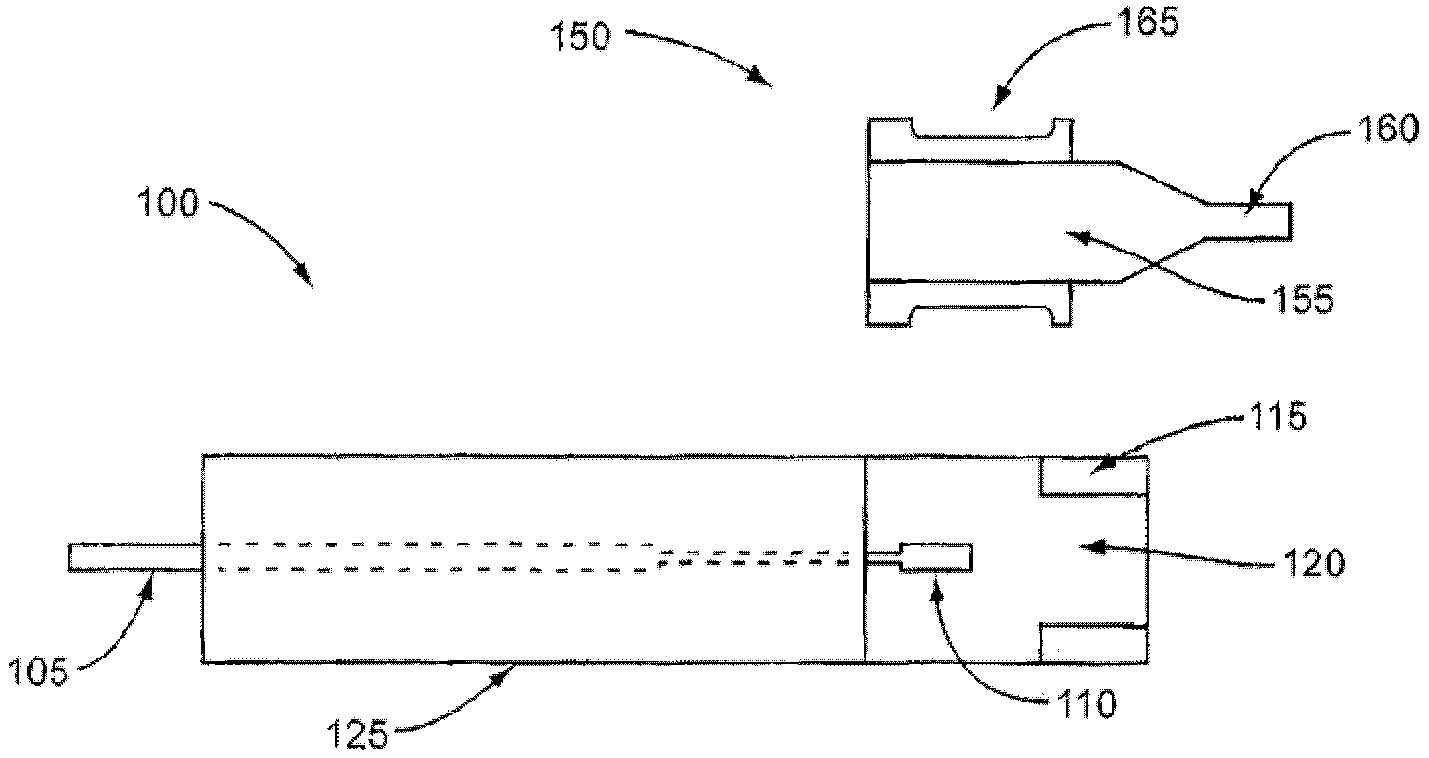

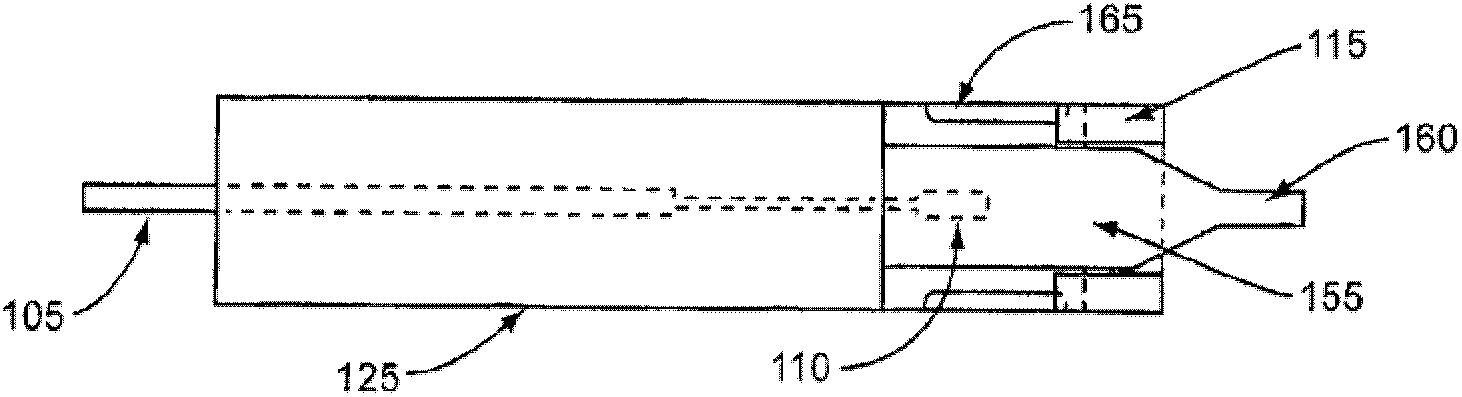

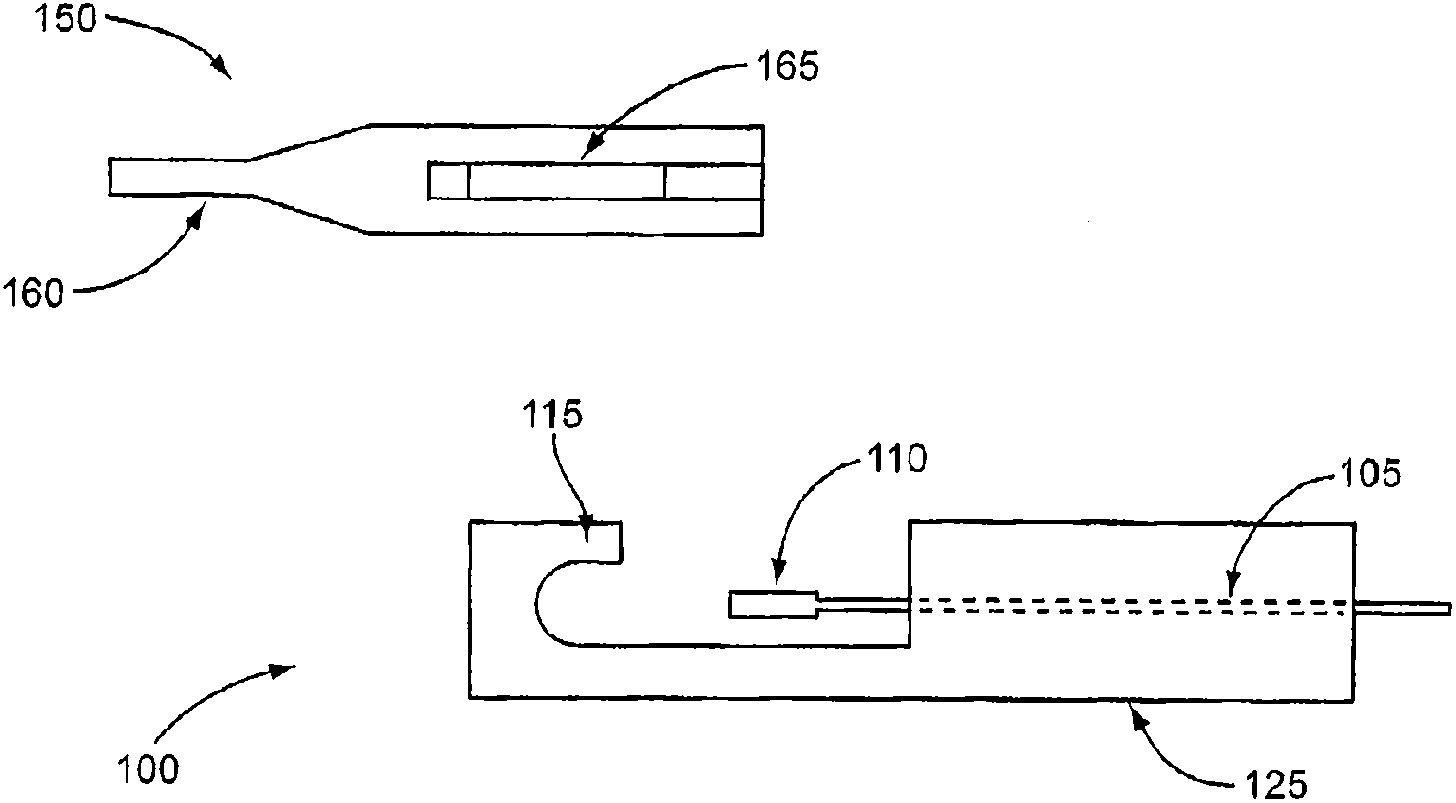

[0019] figure 1 is a top cross-sectional view of the cartridge and handpiece used together as an intraocular lens (IOL) injector. exist figure 1 In the illustrated embodiment, the two-piece IOL injector system includes a handpiece 100 and a barrel 150 . The handpiece 100 includes a tubular injector housing 125 housing the plunger rod 105 connected to the plunger 110 . The plunger rod 105 is generally rigid and is connected to the plunger 110 such that movement of the rod 105 is translated into movement of the plunger 110 . In this manner, the plunger 110 is designed to translate longitudinally within the injector housing along the injector housing 125 . Those skilled in the art will appreciate that in some embodiments the plunger rod 105 and plunger 110 may comprise, for example, a molded plastic unitary piece,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com