Continuous in-out bottle washing method and bottle washing machine thereof

A bottle washing machine and bottle washing technology, which is applied to cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of long equipment size, large floor area, and low work efficiency, and achieve shortened size, Reduced footprint and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

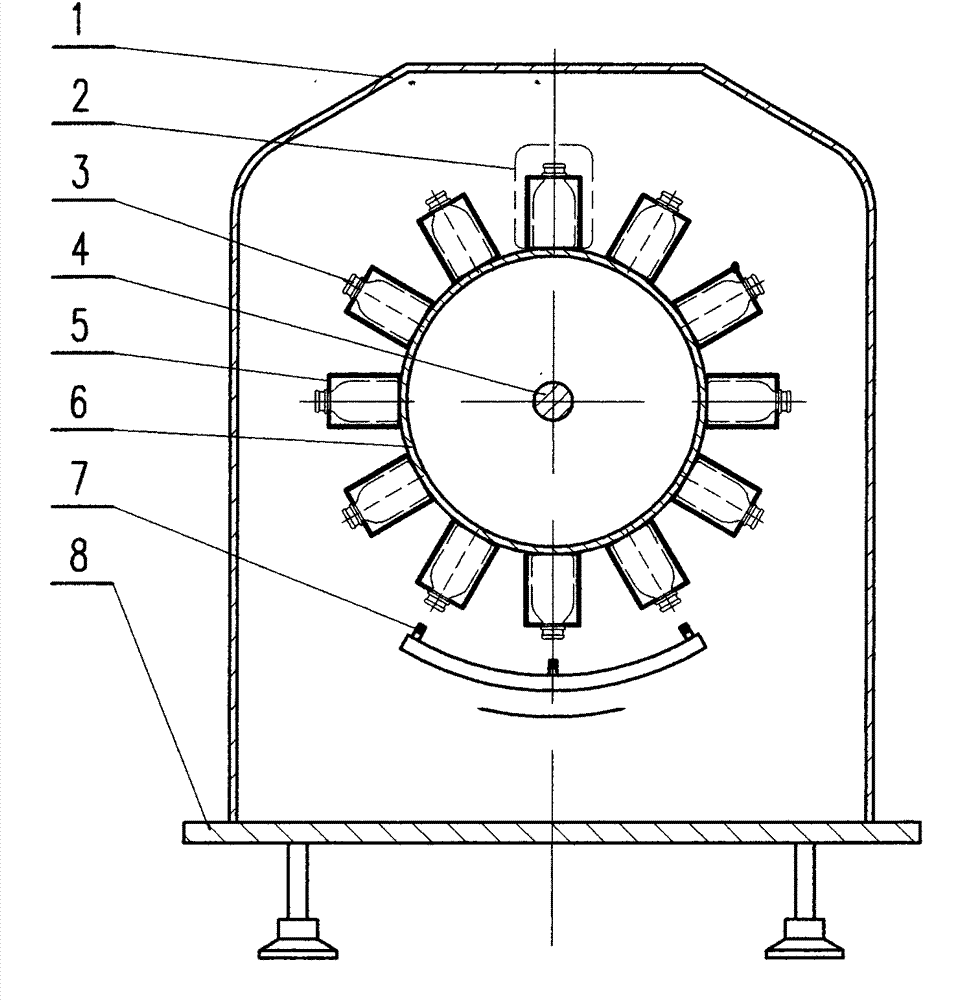

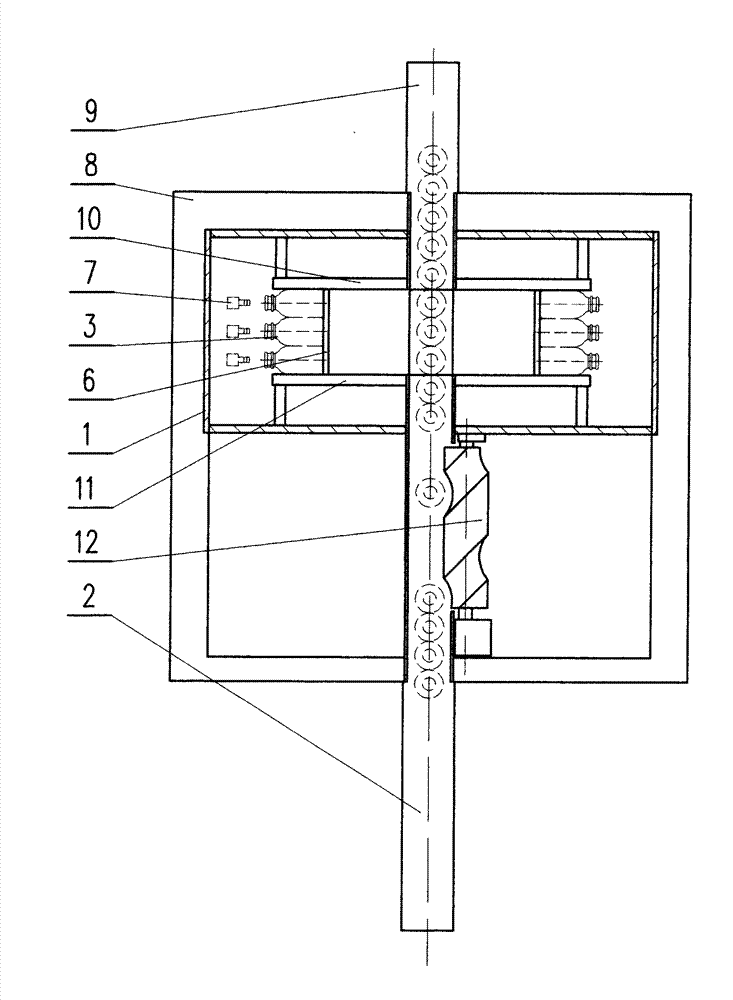

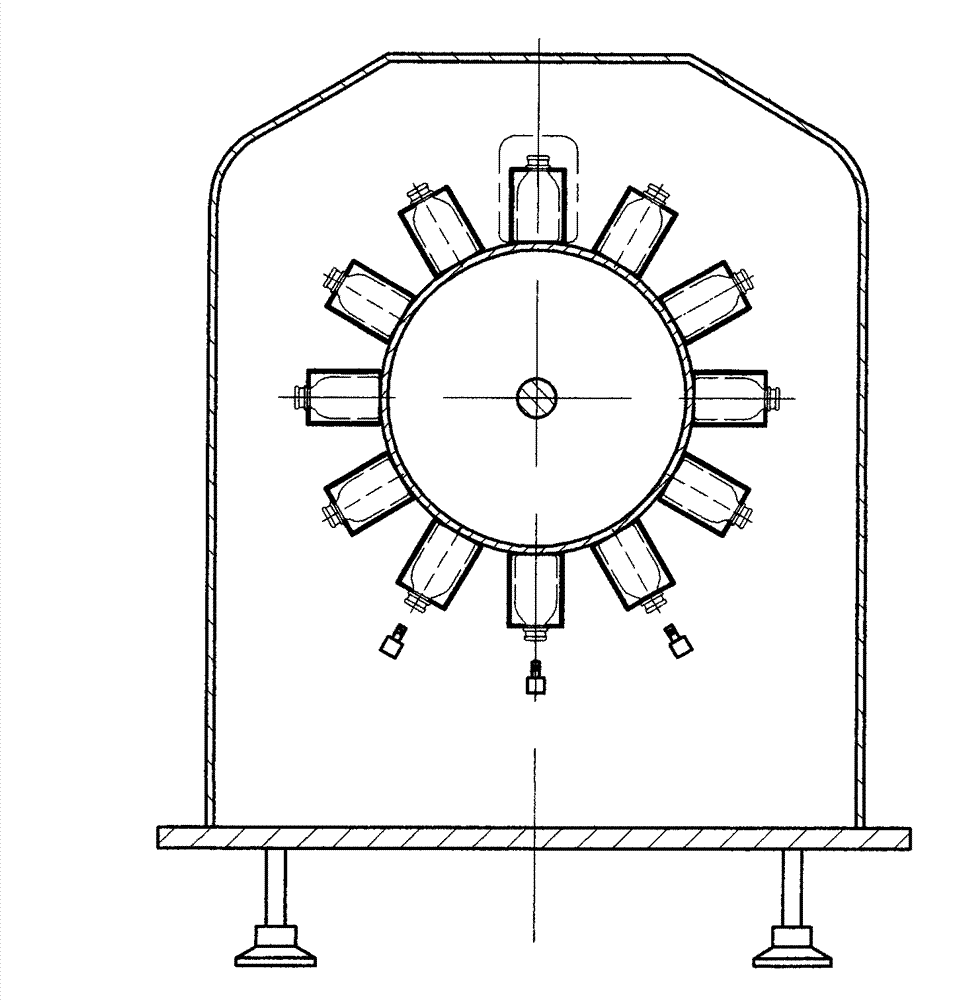

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

[0028] The continuous bottle washing method of the present embodiment, its technological process is as follows:

[0029] A. The bottle feeding track will send the bottle to be washed on it to the bottle feeding place of the bottle washing machine; then,

[0030] B. The bottles to be washed are separated and conveyed by the bottle feeding device (the bottle feeding auger can be used, or other bottle feeding devices, in this case, the bottle feeding auger is used), and the bottles to be washed are separated and transported one by one with the rotating washing bottles in the bottle washing box. Handover of the guardrail on the bottle drum, into the first position inside the guardrail; then,

[0031] C. The bottle to be washed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com