A metal rod drawing device and method

A technology for drawing devices and metal rods, which is applied in the direction of wire drawing dies, etc., can solve the problems of poor surface quality of aluminum wires, poor lubrication effect, and the need for lubricating oil, etc., and achieve high dimensional tolerance accuracy, low failure rate, and simple and quick replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

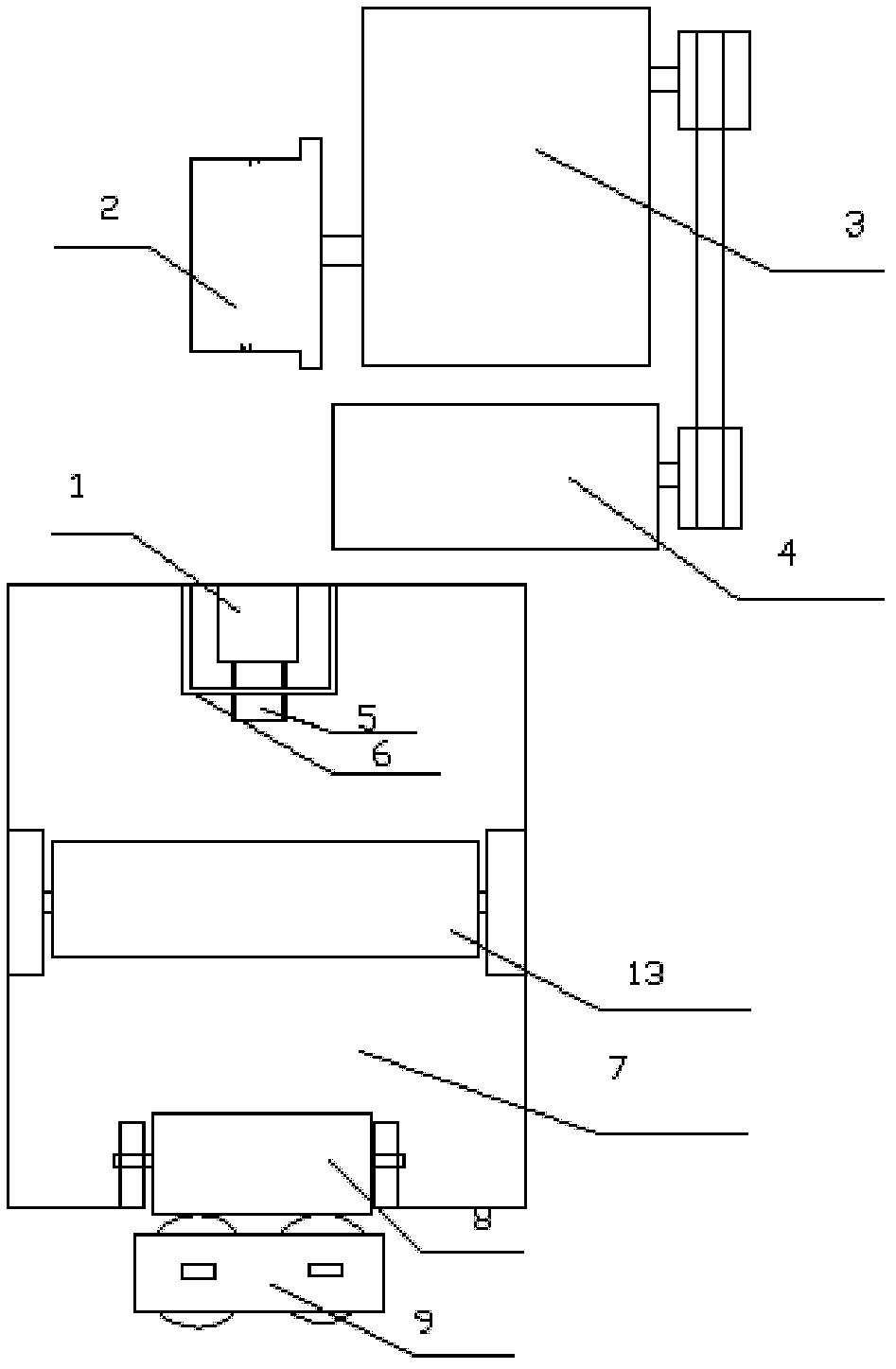

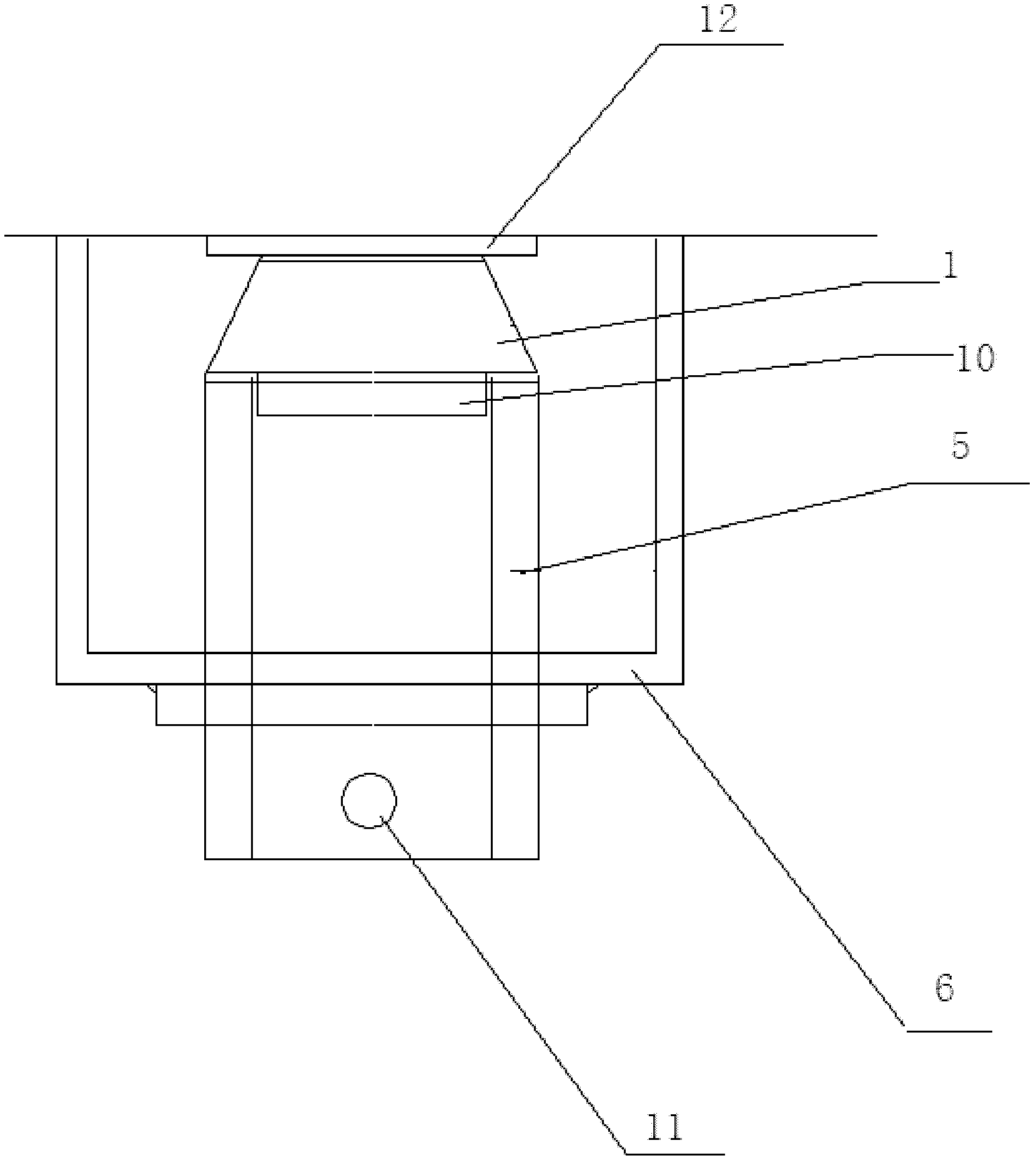

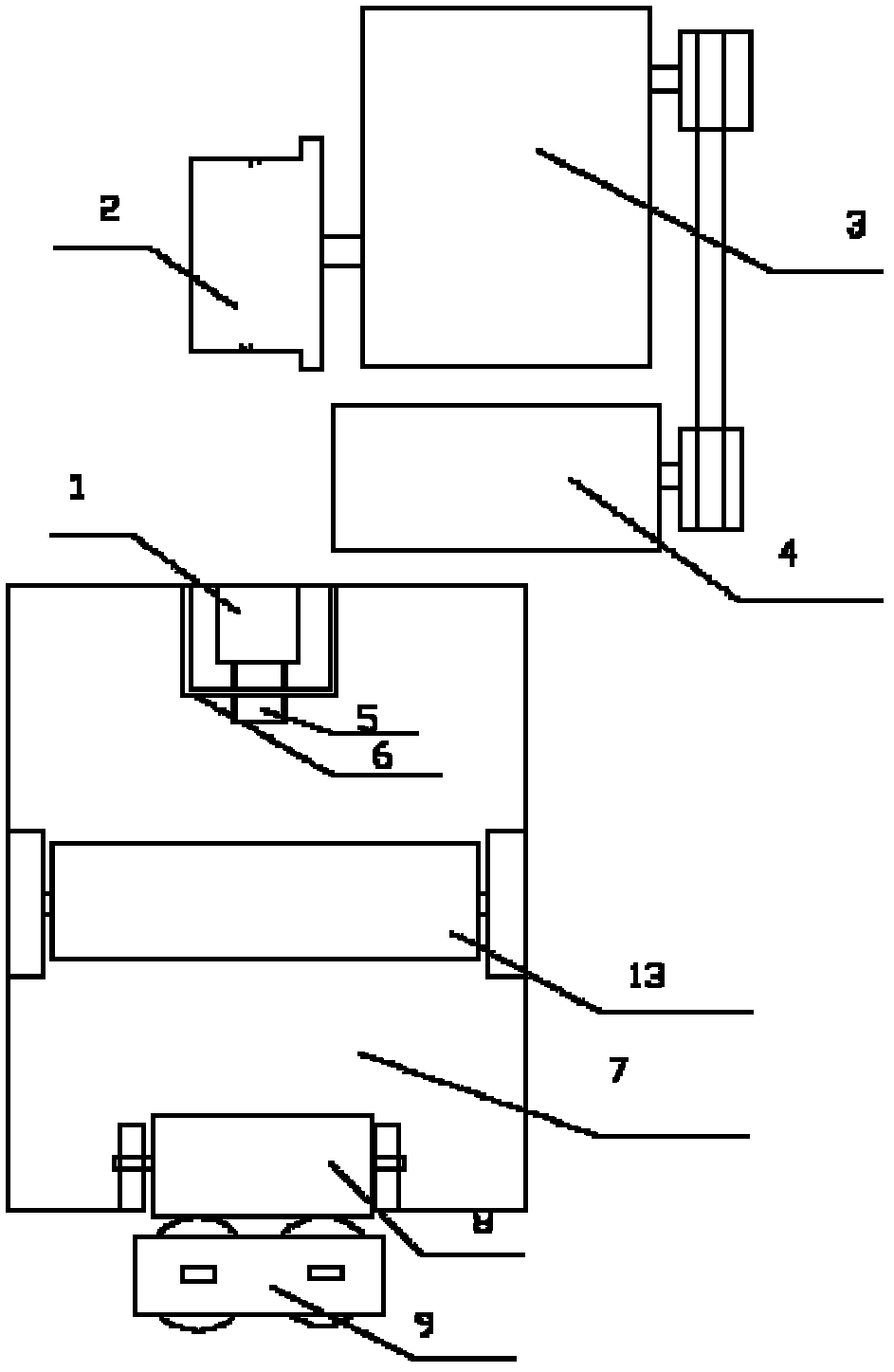

[0028] A method for drawing a metal rod. The metal rod is soaked in liquid lubricating oil for drawing, and the metal rod is extruded and sized at the oil outlet to obtain a metal wire with a smooth surface; the metal rod is an aluminum rod. The drawing speed is 45-50m / min, and the diameter after sizing is 6-18mm.

[0029] The flat tug wheel group, crimping wheel and wire clamping wheel group guide the aluminum wire into the fuel tank smoothly, and ensure that the metal rod penetrates the drawing die horizontally. The aluminum wire passes through the drawing die group to complete the extrusion and sizing of the metal rod, and the aluminum wire is wound on the On the reel, rely on the pulling force of the reel to guide the aluminum wire through the drawing die set to achieve drawing and sizing. Quick change of molds can be realized by cylindrical fastening bolts.

[0030] The present invention can also be used for copper wire drawing, and can be used as a separate aluminum rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com