Three-dimensional single-side variable-cross-section roll-bending forming machine

A technology of variable cross-section and forming machine, which is applied in the field of three-dimensional single-sided variable cross-section roll bending forming machine, can solve the problems of disordered metal flow, reduce mechanical properties of formed parts, and large forming force, and achieve the effect of reasonable mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

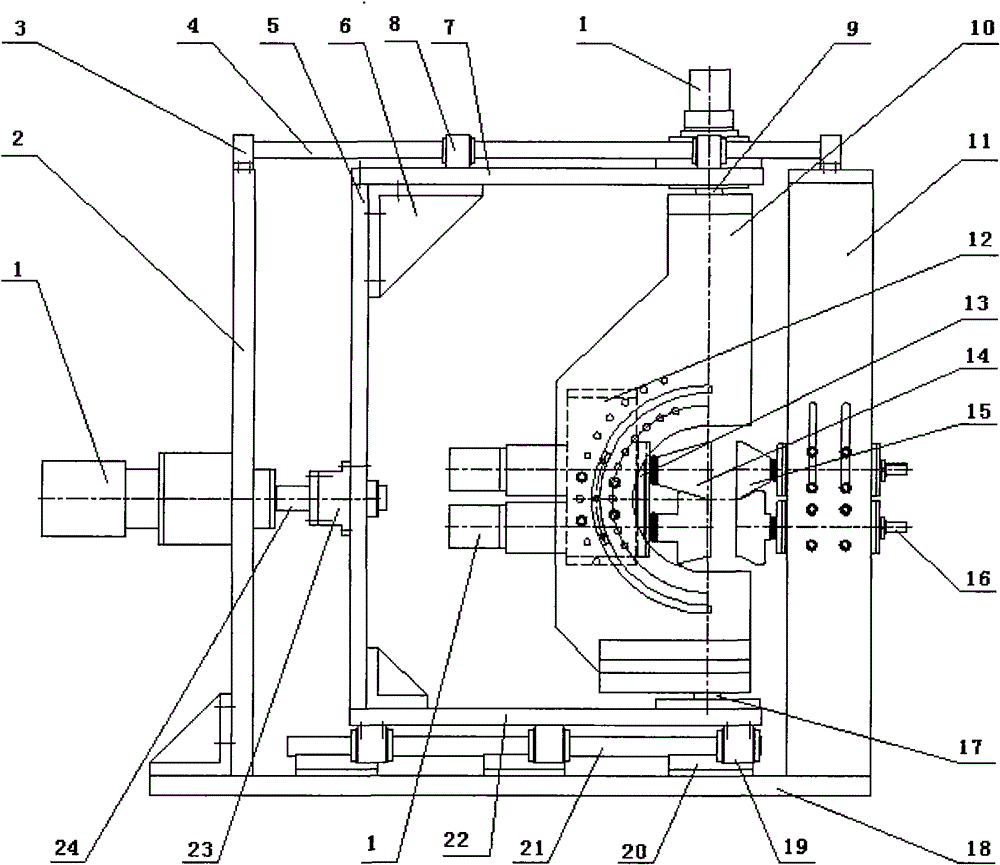

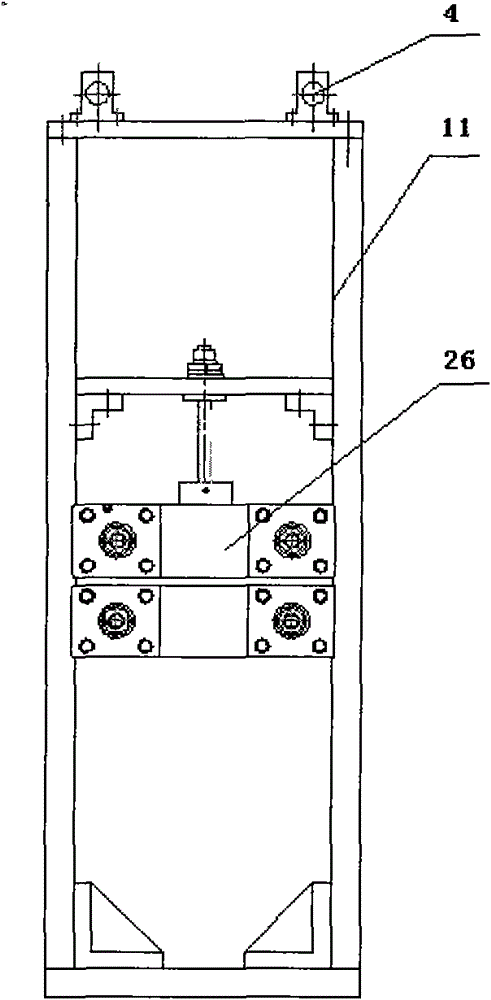

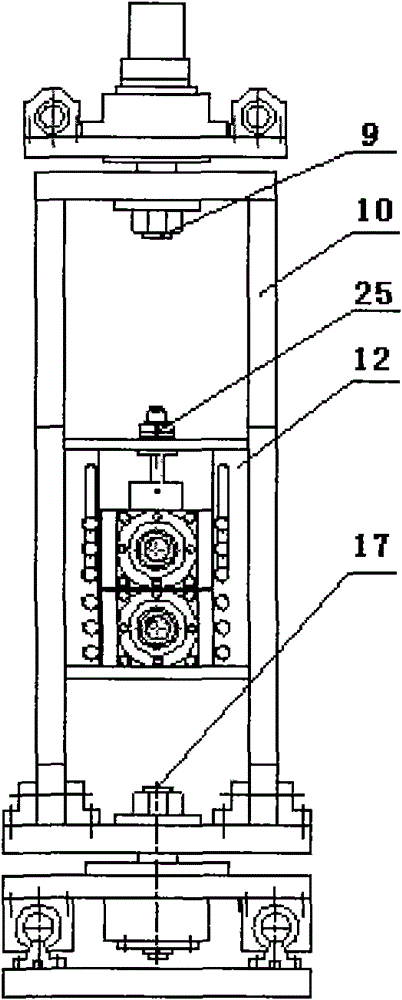

[0024] The three-dimensional single-side variable-section roll forming machine of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] See attached figure 1 As shown in the front view, a three-dimensional single-side variable-section roll forming machine according to the present invention includes a fixed frame and a movable frame movably connected with the fixed frame, forming roll parts, auxiliary roll parts, rotating parts, and a driving mechanism , the rotating part is driven by the driving mechanism and connected with the movable frame, the forming roll part is connected with the rotating part and driven by the driving mechanism, and the auxiliary roller part is arranged at the position opposite to the rotating part Fixed on the frame and driven by a driving mechanism, the rotating part is perpendicular to the plane where the forming roll part and the auxiliary roll part are located, and the forming roll part and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com