A kind of cutting edge punching composite mold

A composite mold, edge trimming and punching technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing equipment and labor costs, reducing production efficiency, etc., reducing equipment and area, and improving work. Efficiency, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

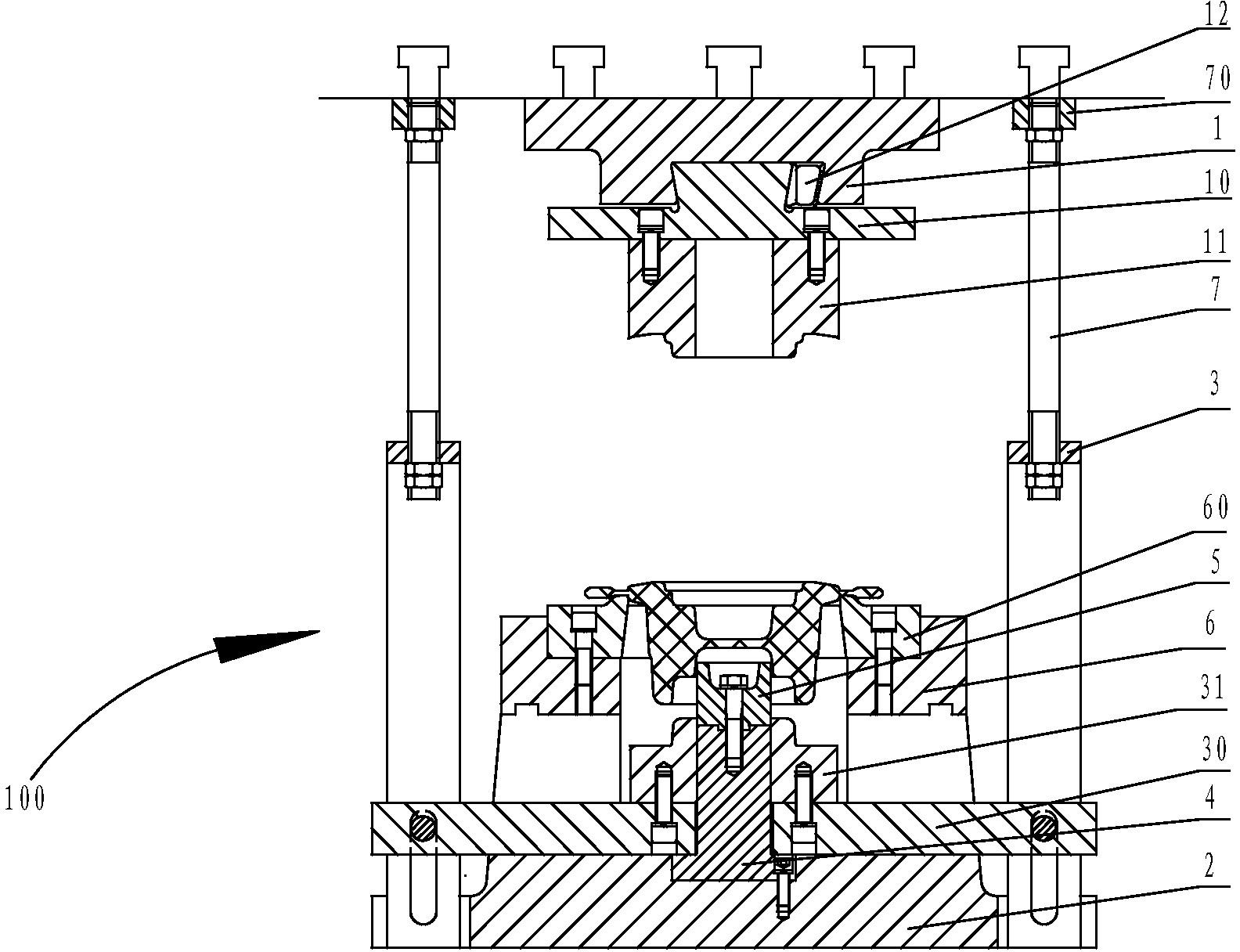

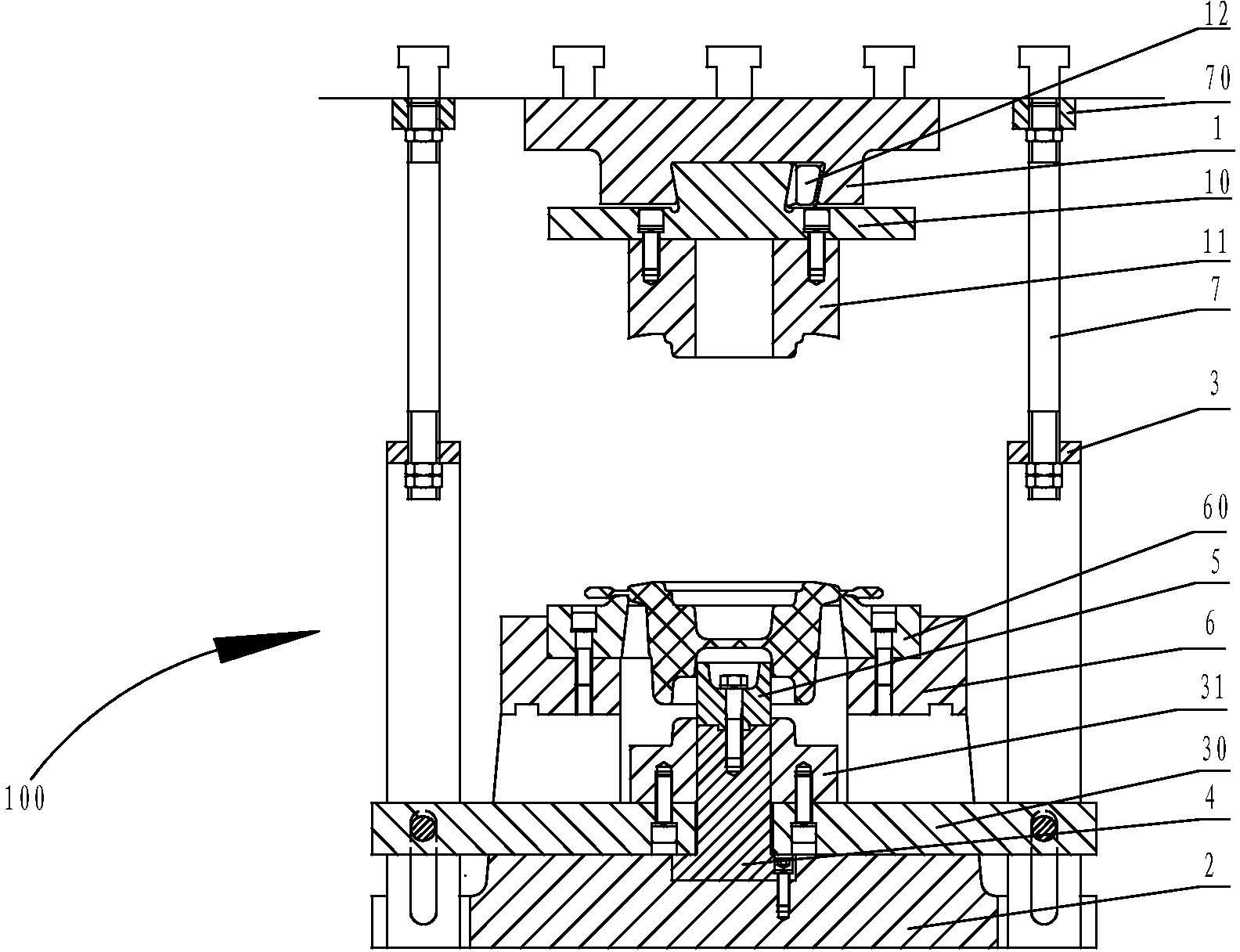

[0009] see figure 1 , a trimming and punching compound mold 100, which includes: an upper mold base 1, a lower mold base 2, a U-shaped plate 3 arranged at both ends of the lower mold base 2, a punching punch base 4 held by the lower mold base 2, The punching punch 5 fixed on the punching punch base 4, the cross arm 30 mounted on the U-shaped plate 3, the ejector 31 fixed on the cross arm 30, the die base 6 mounted on the lower die base 2, the holding The trimming die 60 on the die base 6, the tie rod 7 installed above the U-shaped plate 3, the punch handle 10 installed under the upper die base 1, and the trimming punch 11 fixed to the punch handle 10 , a wedge 12 is provided between the upper die base 1 and the punch handle 10, so that the upper die base 1 and the punch handle 10 are fixed, and a strip 70 is provided above the pull rod 7, so that the pull rod 7 is fixed on the slider of the punching machine, the U-shaped plate 3 and the cross arm 30 are connected by pins, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com