Round plywood manufacturing method

A production method and plywood technology, applied in the field of wood processing, can solve the problems of wasting electric energy, wasting time and effort, wasting raw materials, etc., and achieve the effects of saving freight, saving coal, and saving wages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

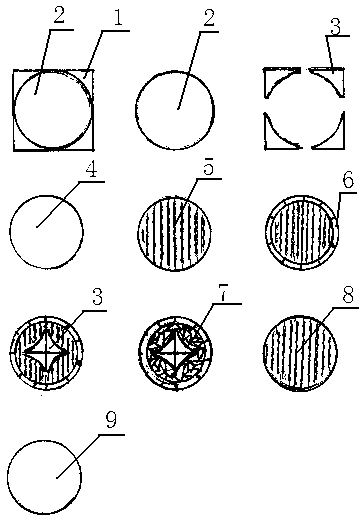

[0020] Such as figure 1 As shown, follow the steps below to make a circular plywood:

[0021] Step 1: Saw the square core board 1 in the center round panel 2 and four corners 3; wherein, the circular panel 2 takes the largest inner circle of the square core plate 1;

[0022] The second step: put a base circular panel 4 on the operating table, bond a piece of equal-diameter first circular rubber sheet 5 on the base circular panel 4, and glue the circular rubber sheet 5 along the circumference on the first circular rubber sheet 5 Connect a circle of side strips 6;

[0023] Step 3: Bond four corners 3 obtained in the first step with the center of the circle as the midpoint on the first circular rubber sheet 5;

[0024] The fourth step: bond the broken core board 7 on the blank space between the edge strip 6 and the four corners 3 on the first circular rubber sheet 5;

[0025] The fifth step: bonding the second circular rubber plate 8 on the first circular rubber plate 5 bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com