Adjusting device for built-in sunroof of automobile

An adjustment device and built-in technology, which is applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of time and personnel waste, large difference in roof surface, water leakage, etc., so as to save time and labor, reduce repeated adjustments, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

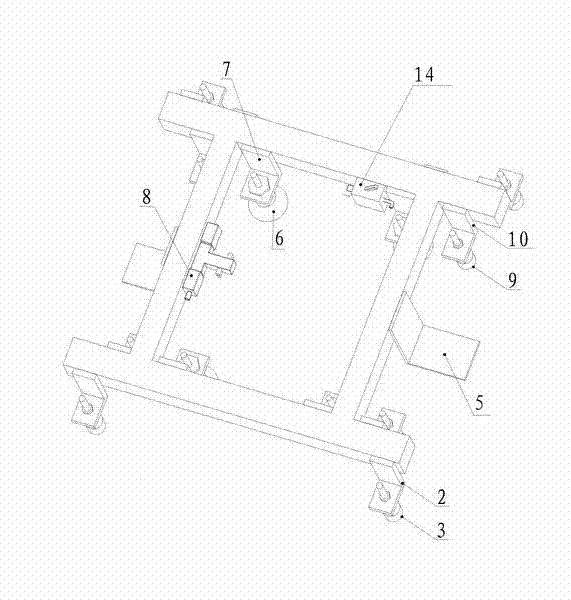

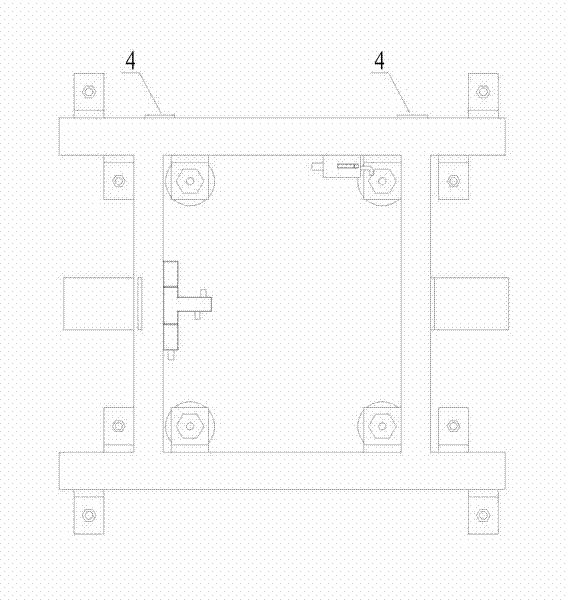

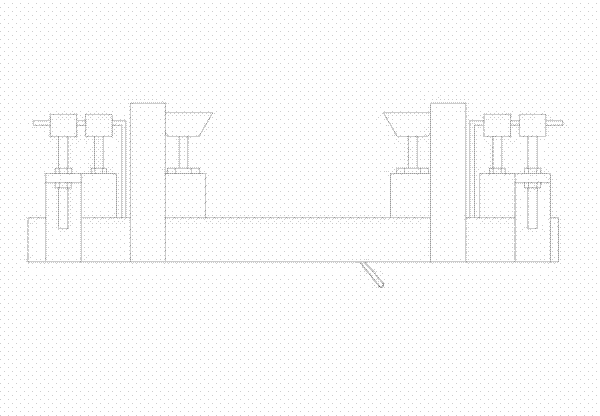

[0034] figure 1 — Figure 4 Shown is an adjustment device for a built-in sunroof of an automobile, each component of which is fixed on the support frame 1 . The support frame 1 is a square hollow frame structure formed by the fixed connection of two vertical and two horizontal frame bars. Aluminum alloy materials with light specific gravity can be selected. The frame bars of the support frame 1 are provided with weight-reducing holes and installation grooves. (not shown in the figure).

[0035] Taking the plane where the support frame 1 is located as the horizontal plane as a reference, the support frame 1 is fixed with a vehicle body positioning block 3 extending downward from the plane where the vertical support frame 1 is located, a spacer 4, an overall positioning device for the sunroof, and a glass positioning block 9. Sucker 6 and its control mechanism.

[0036] The body positioning block 3 is four polyurethane rods of the same unit, and the bottom end is a horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com