Method for selectively metallizing plastic surface

A selective and metallization technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problem of no selectivity in the generation of patterns, and achieve the effect of easy control and widening the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

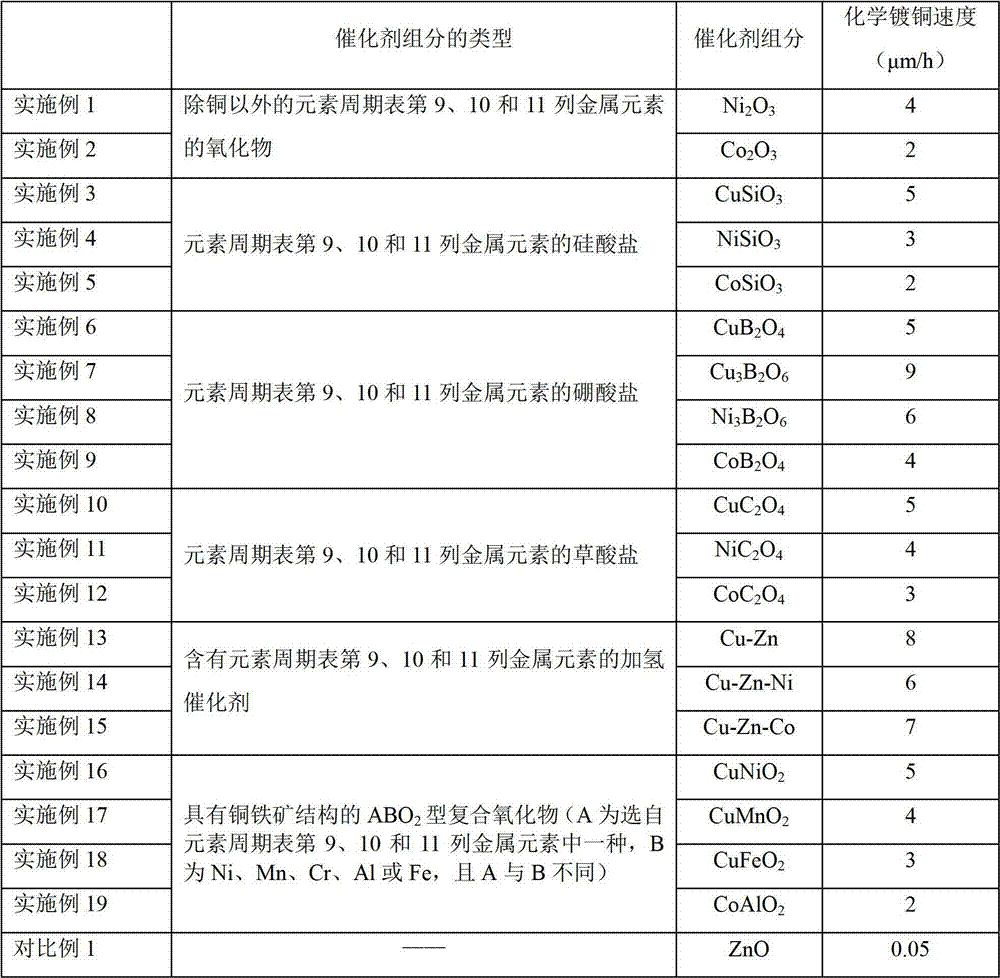

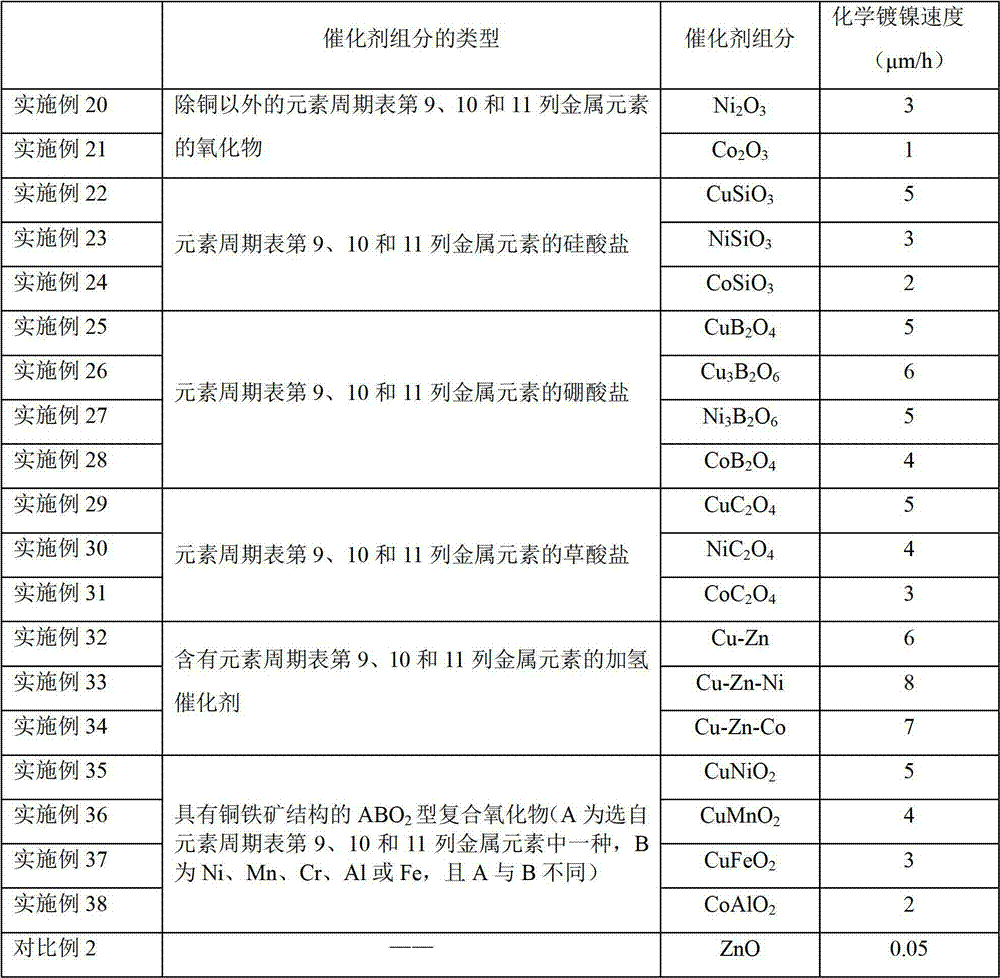

Examples

Embodiment 1

[0042] This example is used to illustrate the plastic composition of the present invention and the method for selective metallization of plastic surfaces.

[0043] 100g of Ni with an average particle diameter of 50 nm 2 o 3 And the talc powder of 10g joins in the polycarbonate of 1000g, mixes at a high speed, obtains the plastic composition of the present invention, then it is transferred to extruder and extruded granulation, and then it is transferred to injection molding machine Plastic samples were injection molded to a thickness of 2 mm. Place the plastic sample on the laser sample stage, focus the laser, and the computer program controls the movement of the beam or sample stage. The laser used is Han’s YLP-20 laser, and the laser parameters are: wavelength 1064nm, scanning speed 1000mm / s, step size 9μm , delay 30μs, frequency 40KHz, power 3W, filling pitch 50μm. After laser etching, the plastic samples were decontaminated and then placed in CuSO 4 ·5H 2 O: 0.12mol / L,...

Embodiment 2

[0045] This example is used to illustrate the plastic composition of the present invention and the method for selective metallization of plastic surfaces.

[0046] 100 g of Co with an average particle diameter of 100 nm 2 o 3 And the glass fiber of 30g joins in the PC of 5000g, mixes evenly at a high speed, obtains the plastics composition of the present invention, then it is transferred to the extruder to extrude granulation, then it is transferred to the injection molding machine and injected into 2 mm thick plastic samples. Place the plastic sample on the laser sample stage, focus the laser, and the computer program controls the movement of the beam or sample stage. The laser used is Han’s YLP-20 laser, and the laser parameters are: wavelength 300nm, scanning speed 5000mm / s, step size 3μm , delay 60μs, frequency 40KHz, power 3W, filling pitch 30μm. After laser etching, the plastic samples were decontaminated and then placed in CuSO 4 ·5H 2 O: 0.12mol / L, Na 2 EDTA·2H ...

Embodiment 3

[0048] This example is used to illustrate the plastic composition of the present invention and the method for selective metallization of plastic surfaces.

[0049] 100 g of CuSiO with an average particle diameter of 500 nm 3 And the kaolin of 70g joins in the 10000g polyethylene terephthalate, mixes at a high speed, obtains the plastic composition of the present invention, then it is transferred to extruder granulation in the extruder, then it is transferred to Plastic samples with a thickness of 2 mm were injection molded in an injection molding machine. Place the plastic sample on the laser sample stage, focus the laser, and the computer program controls the movement of the beam or sample stage. The laser used is Han’s YLP-20 laser, and the laser parameters are: wavelength 10600nm, scanning speed 8000mm / s, step size 6μm , delay 100μs, frequency 30KHz, power 4W, filling pitch 40μm. After laser etching, the plastic samples were decontaminated and then placed in CuSO 4 ·5H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com