Installation Technology of Basin Rubber Bearing of Cast-in-situ Bridge

A rubber bearing and installation process technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty and lack of fullness, and achieve the effect of ensuring quality, reducing grouting difficulty, and increasing grouting space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

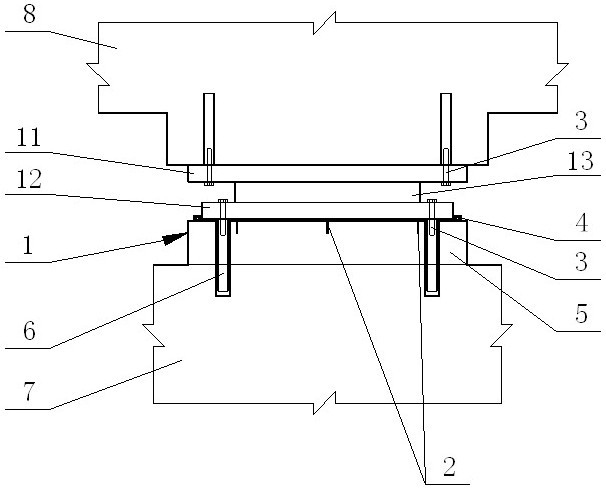

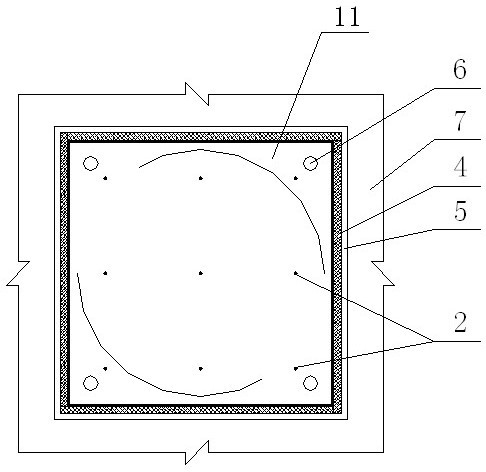

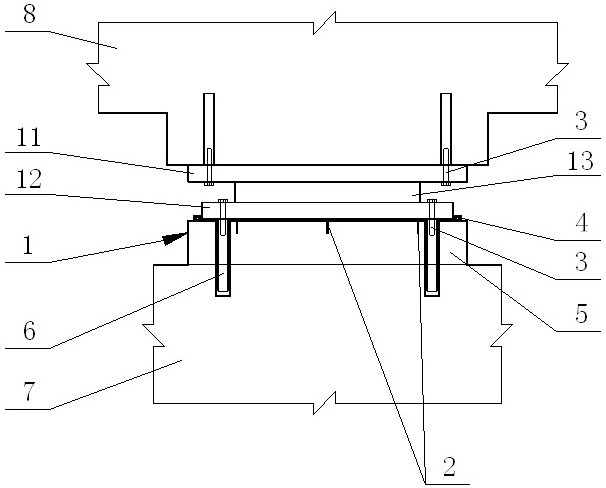

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] An installation process of a cast-in-place bridge basin type rubber bearing, the steps are as follows:

[0031] 1) During the construction of bridge piers, cap beams or abutment caps, reserve bolt holes according to the support anchor bolt parameters provided by the support manufacturer, and calculate the elevation according to the support after the concrete of the pier, cap girder or abutment cap reaches a certain strength (generally The thickness of the epoxy mortar shall be within 5mm when the support is reserved for installation) and the cushion stone concrete shall be poured.

[0032] 2) Before installation, check whether the model of the support meets the design requirements; whether the qualification certificate and test report of the support are complete and valid.

[0033] 3) When the cushion stone concrete reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com