An Assembled Jacking Method for Severe Collapse of Small Section Tunnel

A small-section, tunnel technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve problems such as small tunnel sections and difficult linings, achieve obvious effects, solve poorly handled problems, and have practical market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

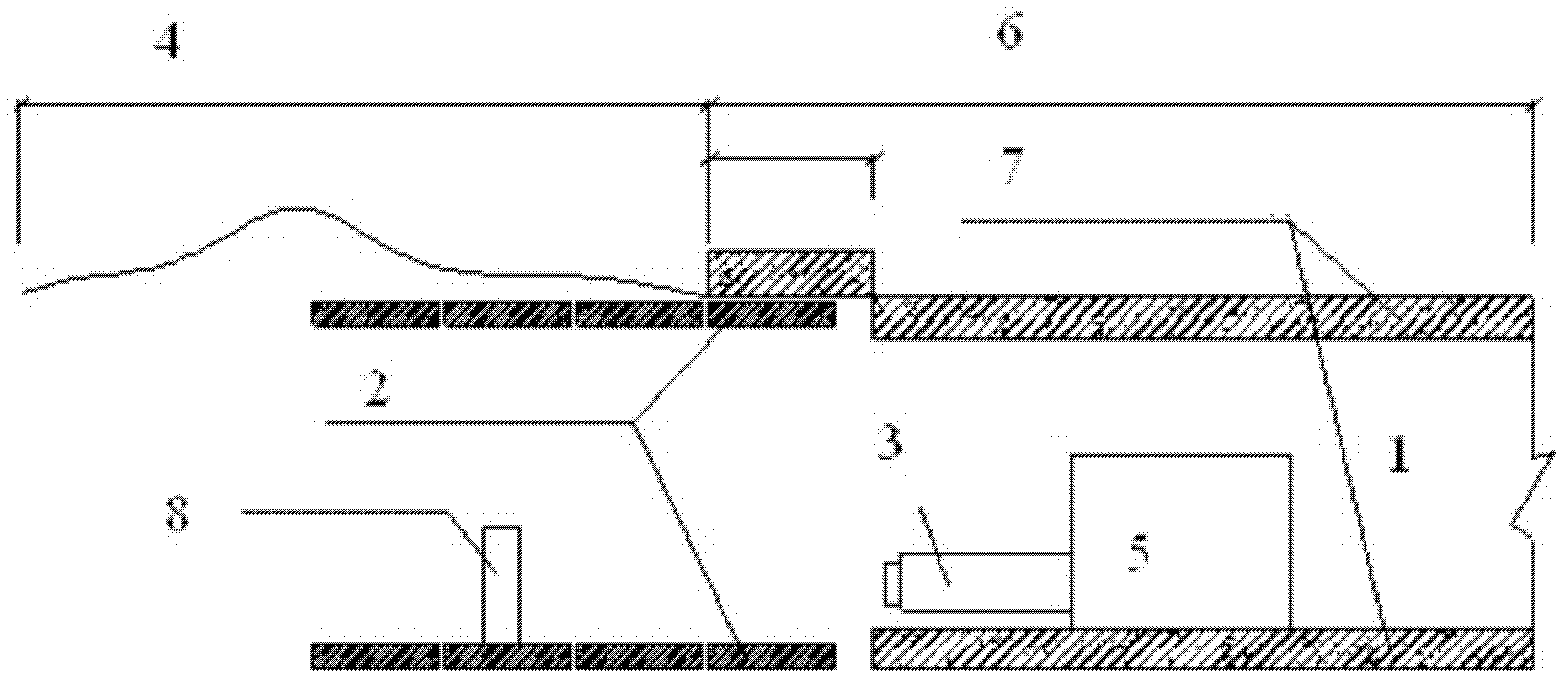

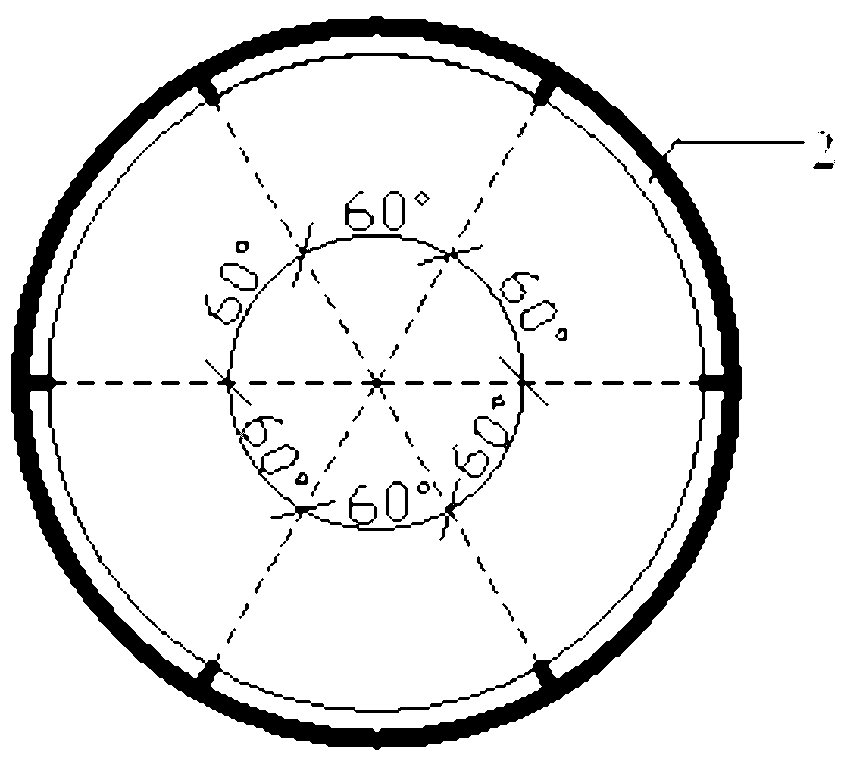

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

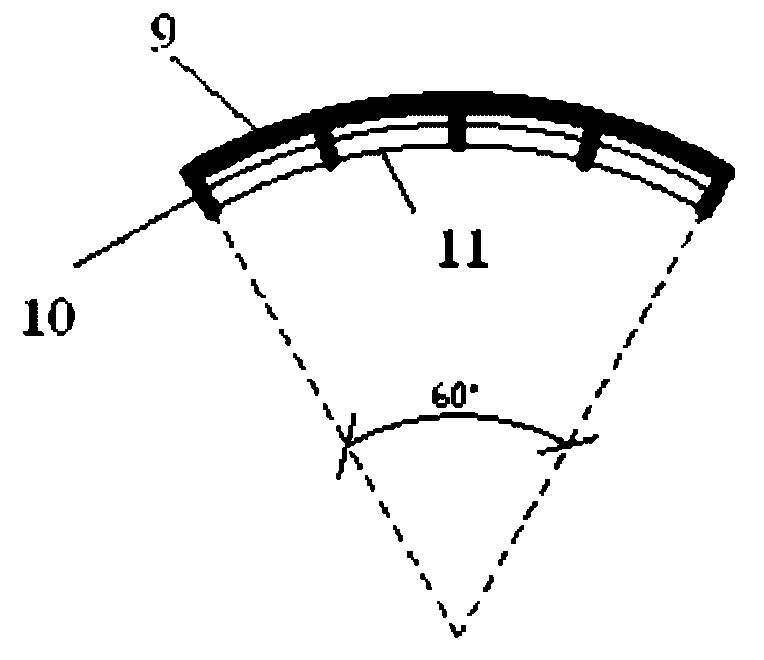

[0024] Take the diversion tunnel project of Yichang No. 2 Water Plant as an example. The tunnel mileage ranges from K0+154.85 to K2+687.585, with a total length of 2532.735m, a lining thickness of 0.35m, an inner diameter of 1.7m, an outer diameter of 2.4m, and a longitudinal slope of 1 / 1000. The tunnel adopts composite lining, and the initial lining is made of C25 concrete prefabricated blocks with a thickness of 0.15m, a width of 0.2m, an inner radius of 1.05m, an outer radius of 1.2m, and an angle of 45° at both ends. After the primary lining is completed, a 200mm thick reinforced concrete secondary lining is carried out.

[0025] During the construction process, the surrounding rock between the No. 1 flat tunnel and the No. 2 vertical shaft is pebble soil and there is a section of groundwater. The pebble soil poured into the cave in the form of mud-rock flow afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com