Controllable four-probe graphite resistance testing device

A technology of graphite resistance and testing device, applied in the field of graphite, can solve the problem of accurate value of measurement results without a fixed device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

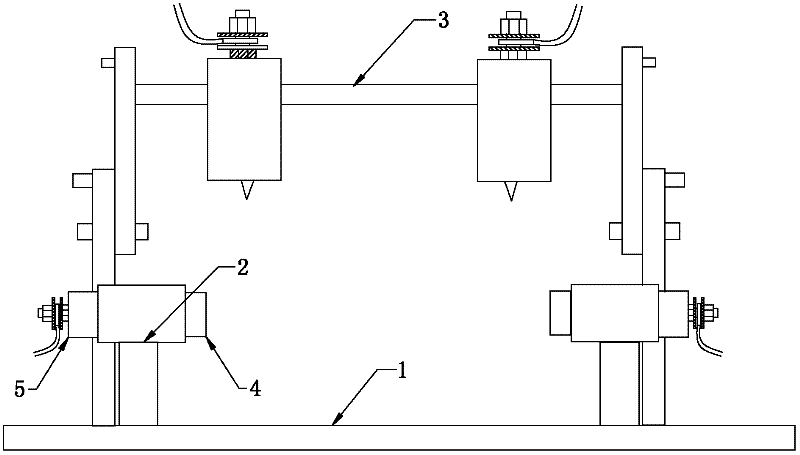

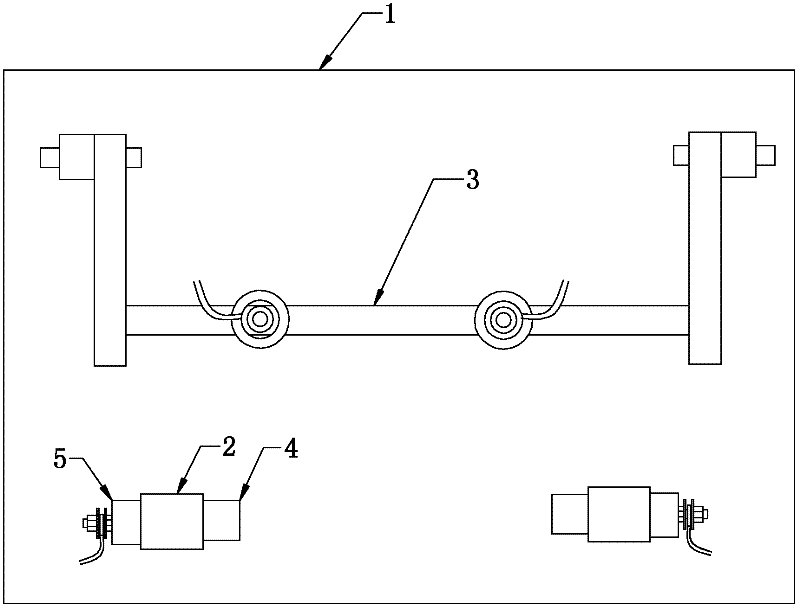

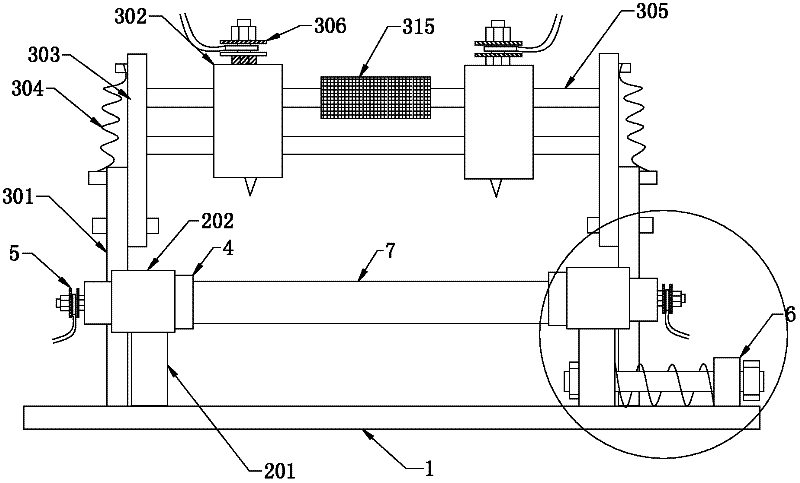

[0034] Such as figure 1 , 2As shown, the technical solution disclosed in the present invention includes a measurement platform 1 and a current measurement device 2 and a voltage measurement device 3 installed on the measurement platform, wherein the current measurement device 2 and the voltage measurement device 3 are installed side by side on the measurement platform 1, The current measurement device includes a fixed frame 201 connected to the measurement platform, a current probe base 5 and a graphite rod clamping device 4 installed on the fixed frame, and there are two fixed frames 201 located on the same axis, wherein the current probe base 5 Used to connect the two current access terminals 509 of the tester, the installation positions of the graphite rod clamping devices on the two fixed frames correspond to the graphite rod 7 to be tested, at this time the current probe base and the graphite rod to be tested The two ends are in contact to supply the measuring current fo...

Embodiment 2

[0039] Such as figure 1 , 2 , As shown in 3 and 4, on the basis of the foregoing embodiments, a fixed pipe 202 is installed on the top of the fixed frame 201 in this program, the center of the fixed pipe circle on the two fixed frames is located on the same axis, and the two ends of the fixed pipe are respectively installed The rotating tube and the current probe seat, the fixed tube 202 is provided with a retaining ring 204 with a reduced diameter, the retaining ring is used to prevent the rotating tube 401 or the current probe seat 5 from going too deep into the fixed tube, wherein the inner diameter of the rotating tube 401 is greater than or equal to the To measure the diameter of the graphite rod 7, the rotating tubes on the two fixed tubes are opposite, and the graphite rod to be measured is inserted in the two rotating tubes. The current probe base 5 includes a probe rod 502, a spring 503, a plug tube 504 and a current probe fixing device 505. The above components are ...

Embodiment 3

[0042] Such as Figure 11 As shown, in order to improve the accuracy of the angle of the graphite rod 7 to be measured when it is overturned, this solution is based on the foregoing embodiments, and an angle mark 402 is set at the nozzle of the rotating tube 401, and the angle mark is at the nozzle of the rotating tube. 90 degrees is the standard setting four, and at the same time set the reference mark 203 on the nozzle of the fixed tube 202. When rotating the graphite rod, you only need to rotate the rotating tube, and align the flip mark of the next measurement position with the reference mark, that is, the graphite to be tested is realized. The 90 standard angle flip of the rod completely avoids the flip error and improves the accuracy of the measurement results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com