Liquid crystal test box and manufacturing method thereof

A technology of liquid crystal testing and manufacturing methods, applied in nonlinear optics, instruments, optics, etc., can solve the problem that the cost cannot be further reduced, and achieve the effect of less shielding and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0054] Figure 1A to Figure 1E It is a schematic top view of the manufacturing process of the liquid crystal test box according to the first embodiment of the present invention. Please refer to Figure 1A , firstly, a first substrate 100 is provided. In this embodiment, the first substrate 100 is mainly used to carry components on the first substrate 100, and its material may be glass, quartz, organic polymer or other applicable materials.

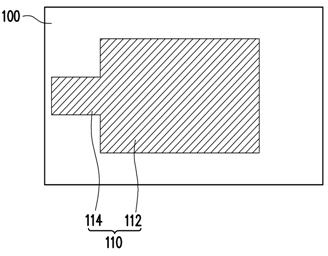

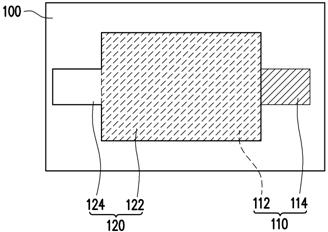

[0055] Please refer to Figure 1B, and then, a first conductive pattern 110 is formed on the first substrate 100 by using a first mask (not shown) as a mask. In this embodiment, the first conductive pattern 110 includes a first working portion 112 and a first terminal portion 114 . The first working part 112 of this embodiment is used to simulate the shared electrode in a fringe field switching (FFS) type liquid crystal display panel. The first working part 112 may be a complete conductive electrode. In other words, the first working ...

no. 2 example

[0072] The manufacturing process of the liquid crystal test box of this embodiment is almost the same as the manufacturing process of the liquid crystal test box of the first embodiment. The difference between the two is only that: the second conductive pattern 130B of this embodiment is different from the second conductive pattern 130 of the first embodiment. Therefore, the manufacturing process of the liquid crystal test box of this embodiment will not be repeated. In the following, only the structural differences between the liquid crystal test cell 1000B of this embodiment and the liquid crystal test cell 100 of the first embodiment will be described.

[0073] Figure 5 It is a schematic top view of the liquid crystal test box of the third embodiment of the present invention. Figure 6 for correspondence Figure 5 The schematic cross-sectional diagram of the liquid crystal test box drawn by the line segment C-C'. Please refer to Figure 5 and Figure 6 , the liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com