Contactless power socket

A power supply socket, non-contact technology, applied in electrical components, circuit devices, electromagnetic wave systems, etc., can solve the problems of easy oxidation of contact parts, unsafe use, and inability to waterproof, and achieve increased overcurrent protection function and convenient waterproof design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

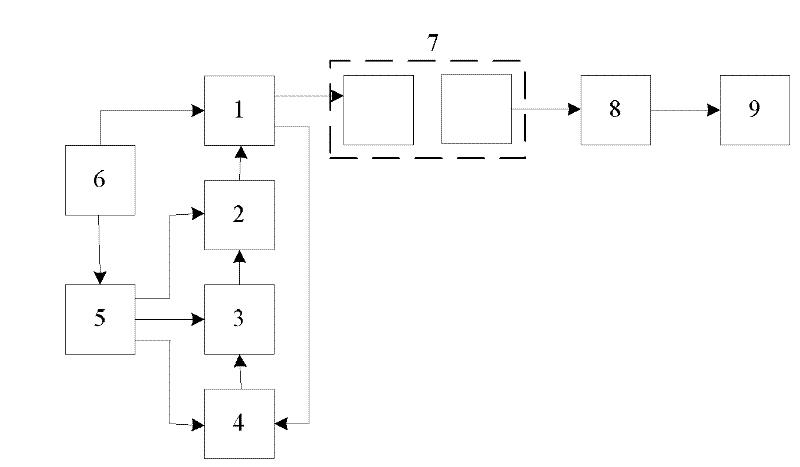

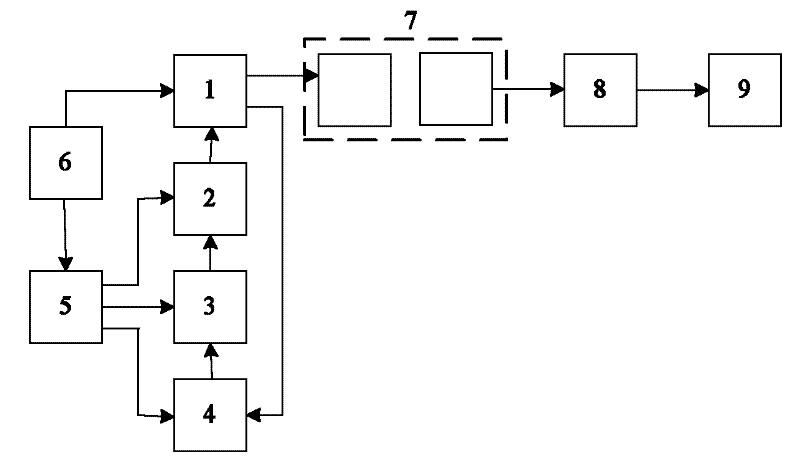

[0016] Such as figure 1 As shown, this embodiment includes: primary side power conversion module 1, controller module 2, signal conditioning and protection module 3, sensor module 4, weak current power supply module 5, strong current power supply module 6, loosely coupled transformer module 7 and secondary side The power processing module 8, wherein: the strong current power supply module 6 is connected to the primary side power conversion module 1 and the weak current power supply module 5 to transmit alternating current, the controller module 2 is connected to the primary side power conversion module 1 to transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com