Preparation technique and application of eye protection plaster

A protective sticker, gel layer technology, applied in ophthalmic treatment, medical science, dressings, etc., can solve the problems of closed eyes of patients and weak protection from direct damage to the eyes, so as to protect the direct damage, protect the eyes, and prevent exposed corneas. inflammation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

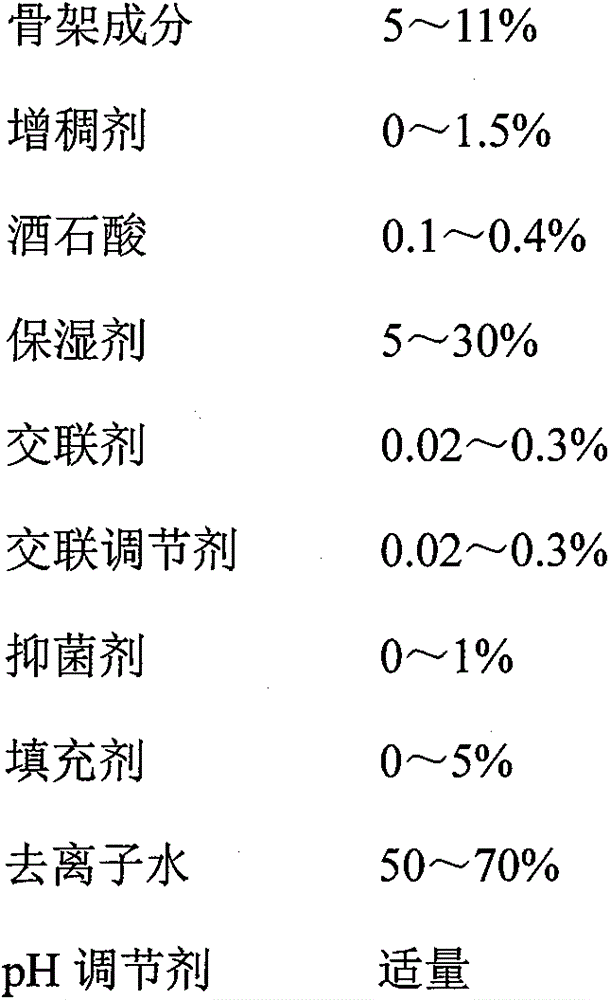

[0026] Take 4% cross-linked sodium polyacrylate, 1.5% CMC, 0.3% aluminum glycylate, 0.2% EDTA, 0.1% paraben according to the proportion of the formula, and disperse the above ingredients in 15 % glycerin and mix well to obtain liquid A.

[0027] Take 0.15% tartaric acid and 0.02% K-90 according to the proportion of the formula, and dissolve them in an appropriate amount of deionized water in turn under the stirring state of 200-1000rpm, spread 3% carbomer evenly on the liquid surface, and let it stand for swelling After 12 to 24 hours, after stirring evenly, add an aqueous solution containing 1% polyvinyl alcohol, and mix evenly to obtain liquid B.

[0028] Add the pre-configured liquid A to the liquid B under stirring at 15-60rpm to form a gel matrix, adjust the pH value to 7.0 with triethanolamine or NAOH, and add deionized water to the required content. Continue stirring and mixing, apply the gel matrix on the coating machine, cut, and then harden to obtain the gel layer a...

Embodiment 2

[0030] Take 8.5% sodium polyacrylate, 0.03% aluminum glycylate and 0.02% EDTA, 0.5% paraben, 5% titanium dioxide according to the proportion of the formula, and the above ingredients are dispersed in 30% moisturizing agent in turn under the stirring state of 15-60rpm and mix well to obtain liquid A.

[0031] Take 0.1% tartaric acid and 0.01% k-90 according to the proportion of the formula, and dissolve them in an appropriate amount of deionized water in turn under the stirring state of 200-1000rpm, spread 0.4% carbomer evenly on the liquid surface, and let it stand for swelling After 12 to 24 hours, after stirring evenly, add an aqueous solution containing 0.1% polyvinyl alcohol and mix evenly to obtain liquid B.

[0032] Add the pre-configured liquid A to the liquid B under stirring at 15-60rpm to form a gel matrix, adjust the pH value to 6.5 with triethanolamine or NAOH, and add deionized water to the required content. Continue stirring and mixing, apply the gel matrix on t...

Embodiment 3

[0034] Take 6% partially cross-linked sodium polyacrylate, 1% CMC, 0.3% aluminum glycylate and 0.3% EDTA, 0.5% paraben, 2% titanium dioxide according to the proportion of the formula, and mix the above ingredients in turn at a speed of 15-60rpm Disperse in 20% humectant and mix well to obtain liquid A.

[0035] Take 0.4% tartaric acid and 0.01% K-90 according to the proportion of the formula, and dissolve them in an appropriate amount of deionized water in turn under the stirring state of 200-1000rpm, spread 2% carbomer evenly on the liquid surface, and let it stand for swelling After 12 to 24 hours, after stirring evenly, add an aqueous solution containing 0.5% polyvinyl alcohol, and mix evenly to obtain liquid B.

[0036]Add the pre-configured liquid A to the liquid B under stirring at 15-60rpm to form a gel matrix, adjust the pH value to 6.5-8.0 with triethanolamine or NAOH, and make up to the required amount of deionized water content, continue to stir and mix, apply the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com