Device for controlling oil smoke concentration detection apparatus

A detection device and a technology for oil fume concentration, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as the loss of purification ability of the purifier, the oil fume purifier has been turned on, and the waste of adsorption media, etc., to reduce the cost of detection , avoid time gaps, and detect the effect of complete data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

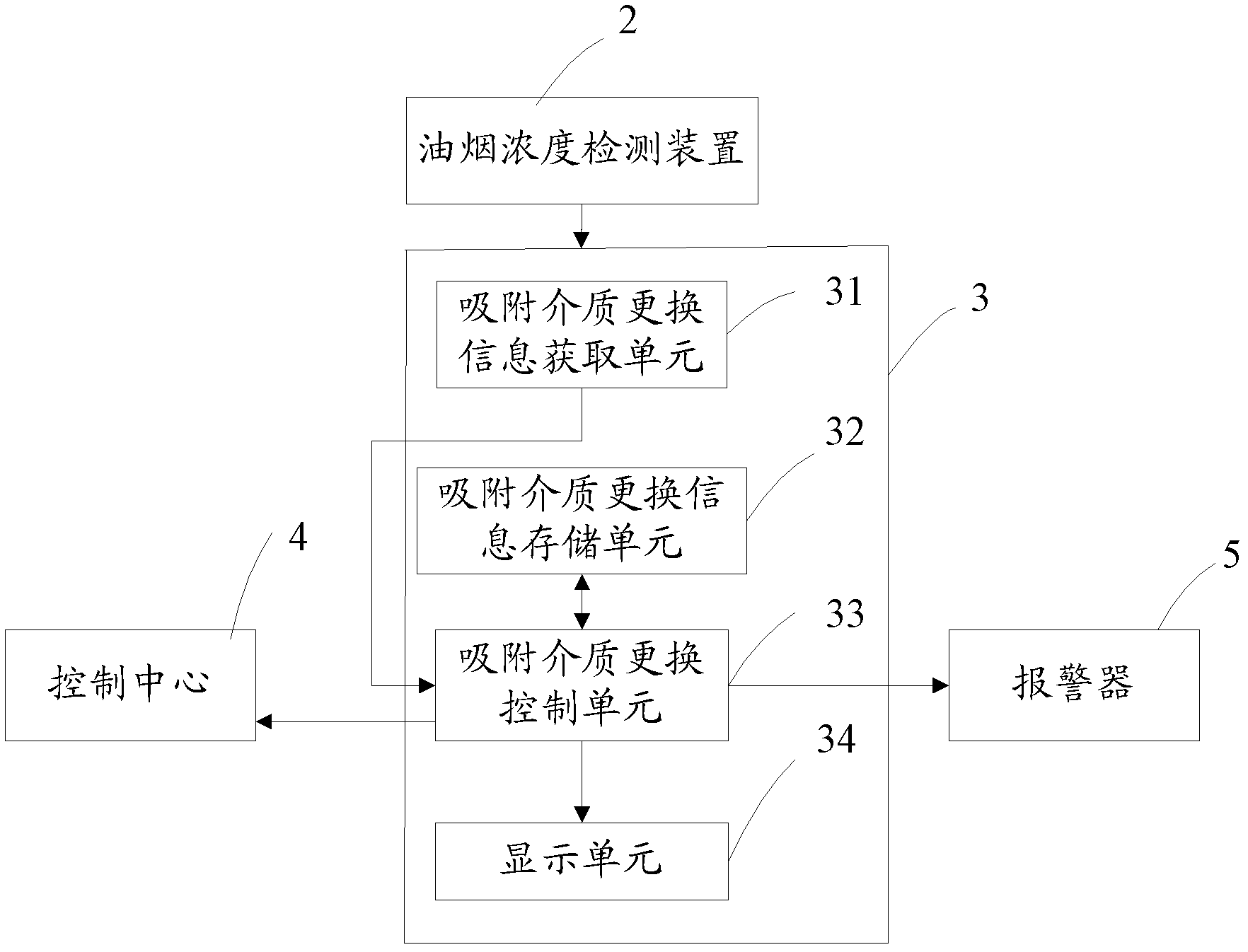

[0043] see figure 1 , the control device of the soot concentration detection device in this embodiment includes:

[0044] The adsorption medium management mechanism 3 is used to obtain the current adsorption medium replacement information, judge the use status of the adsorption medium, and send a prompt signal to the external control center when the adsorption medium is exhausted;

[0045] Among them, the adsorption medium management mechanism includes:

[0046] An adsorption medium replacement information acquisition unit 31, configured to obtain current adsorption medium replacement information;

[0047] The adsorption medium replacement information storage unit 32 is used to store the historical information of the adsorption medium replacement;

[0048] The adsorption medium replacement control unit 33 is used to send a signal indicating that the adsorption medium is exhausted to the external control center 4 before the adsorption medium is exhausted;

[0049] The displa...

Embodiment 2

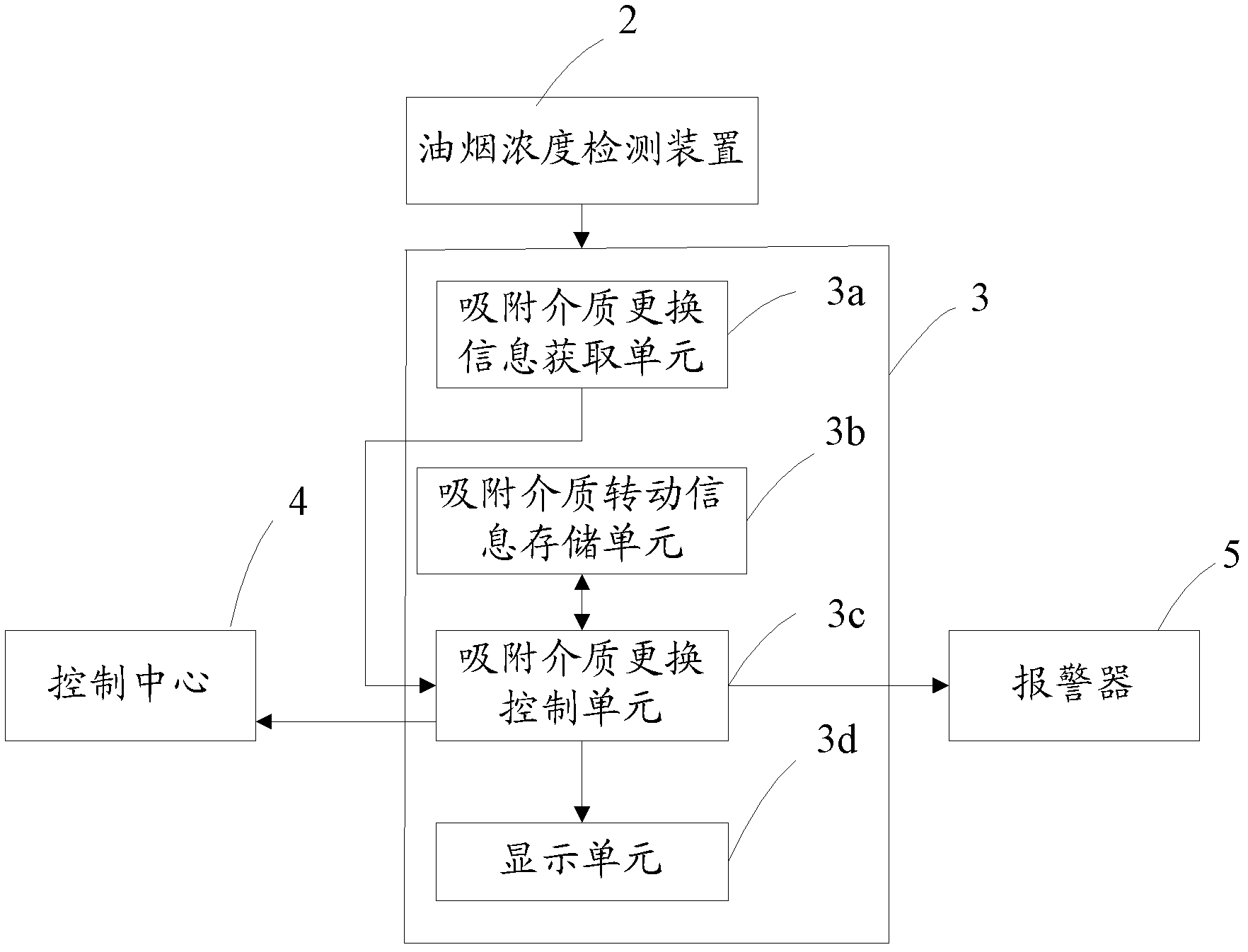

[0058] see figure 2 , The difference between this embodiment and Embodiment 1 lies in the difference of the adsorption medium management mechanism, the adsorption medium management mechanism 3 in this embodiment includes:

[0059] The adsorption medium replacement information acquisition unit 3a is used to obtain the current adsorption medium replacement information;

[0060] The adsorption medium rotation information storage unit 3b is used to store the history information of the adsorption medium rotation;

[0061] The adsorption medium replacement control unit 3c is used to send a signal indicating that the adsorption medium is exhausted to an external control center before the adsorption medium is exhausted;

[0062] The display unit 3d is used to display the usage status of the adsorption medium.

[0063] Among them, the adsorption medium replacement control unit includes:

[0064] The data operation module calculates the total number of rotations per unit of adsorpti...

Embodiment 3

[0069] see image 3 The difference between this embodiment and Embodiments 1 and 2 is that the control device of the oil fume concentration detection device in this embodiment also includes a linkage monitoring mechanism 6 for controlling the operation of the oil fume concentration detection device, including:

[0070] The operating state detection unit 61 of the oil fume purifier is used to receive the operating state signal of the oil fume purifier;

[0071] The linkage control unit 62 starts the oil fume concentration detection device when the operation state signal indicates that the oil fume purifier is started; when the operation state signal indicates that the oil fume purifier is closed, turns off the oil fume concentration detection device;

[0072] An information transceiving unit 63, configured to receive the detection data from the oil fume concentration detection device 2 and transmit it to the external control center 4;

[0073] a storage unit 64, configured to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com