Mine-used inspection vibrating screen

A vibrating screen, linear vibrating screen technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor environmental protection, high labor intensity, high equipment noise, etc. , the effect of high screening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

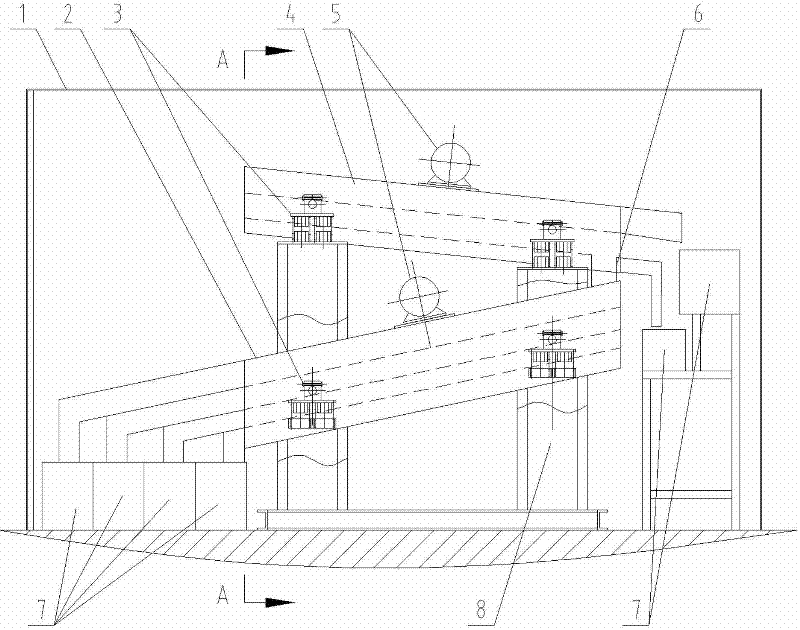

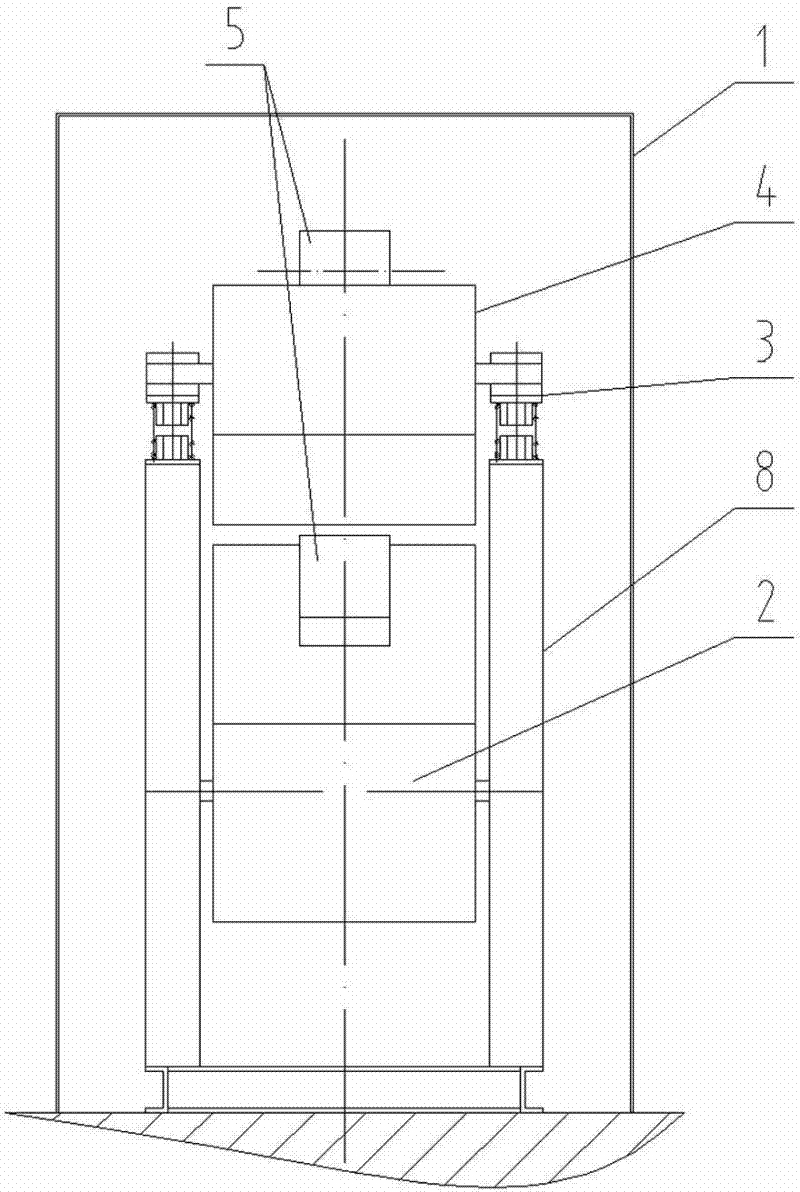

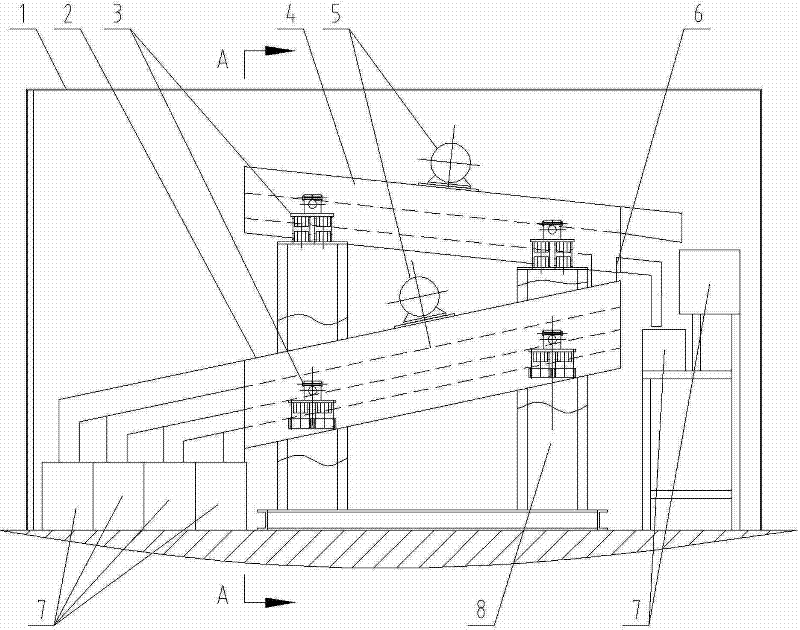

[0022] Such as figure 1 and figure 2 A kind of specific embodiment shown, it comprises closure cover 1, three-stage linear vibrating screen 2, elastic element 3, secondary linear vibrating screen 4, vibrator 5, chute 6, material box 7 and frame 8. The closure cap 1 is shielded from all other components.

[0023] The elastic element 3 includes a spring, an upper support arm and a lower support arm, there is a certain distance between the upper support arm and the lower support arm, and the spring connects the upper support arm and the lower support arm. The frame 8 includes a base and four uprights, and the four uprights are fixed on the four corners of the base. The secondary linear vibrating screen 4 is arranged above the four columns through four elastic elements 3 respectively connected to the four columns, and the upper support arms of the four elastic elements 3 are fixed on the housing of the secondary linear vibrating screen 4, The lower support arm of the elastic e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com