Large-tolerance docking acquisition device focused on space large mechanical arm and rendezvous and docking

A large-scale machine, rendezvous and docking technology, which is applied to the docking device, manipulator, program-controlled manipulator, etc. of space navigation vehicles. It can solve the problem of not being able to capture free-floating, small inertia, unpowered targets in space, and the tolerance range of heterogeneous and isomorphic peripheral docking mechanisms. and other problems, to achieve the effect of increasing reliability and success rate, wide tolerance range, simple driving and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

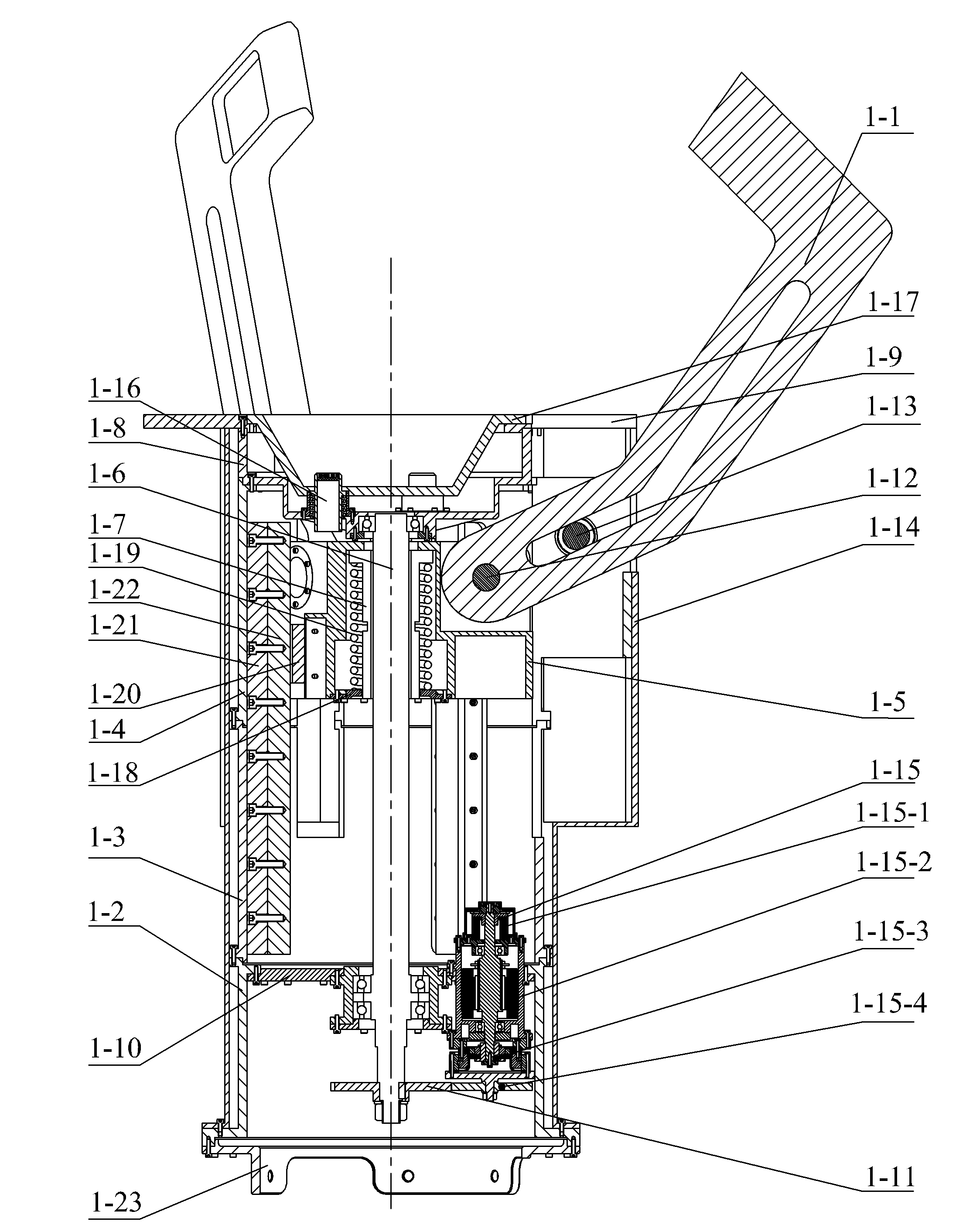

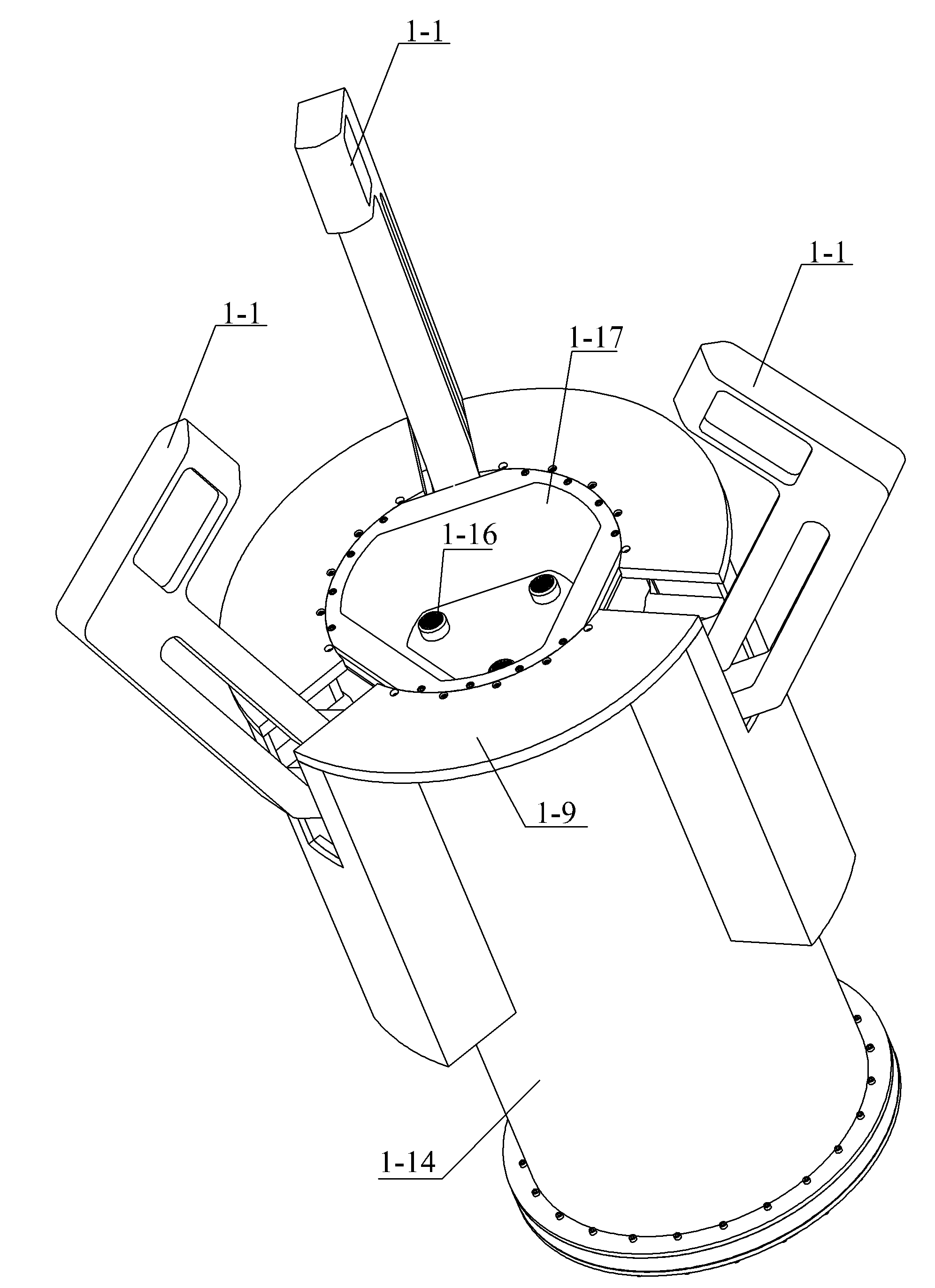

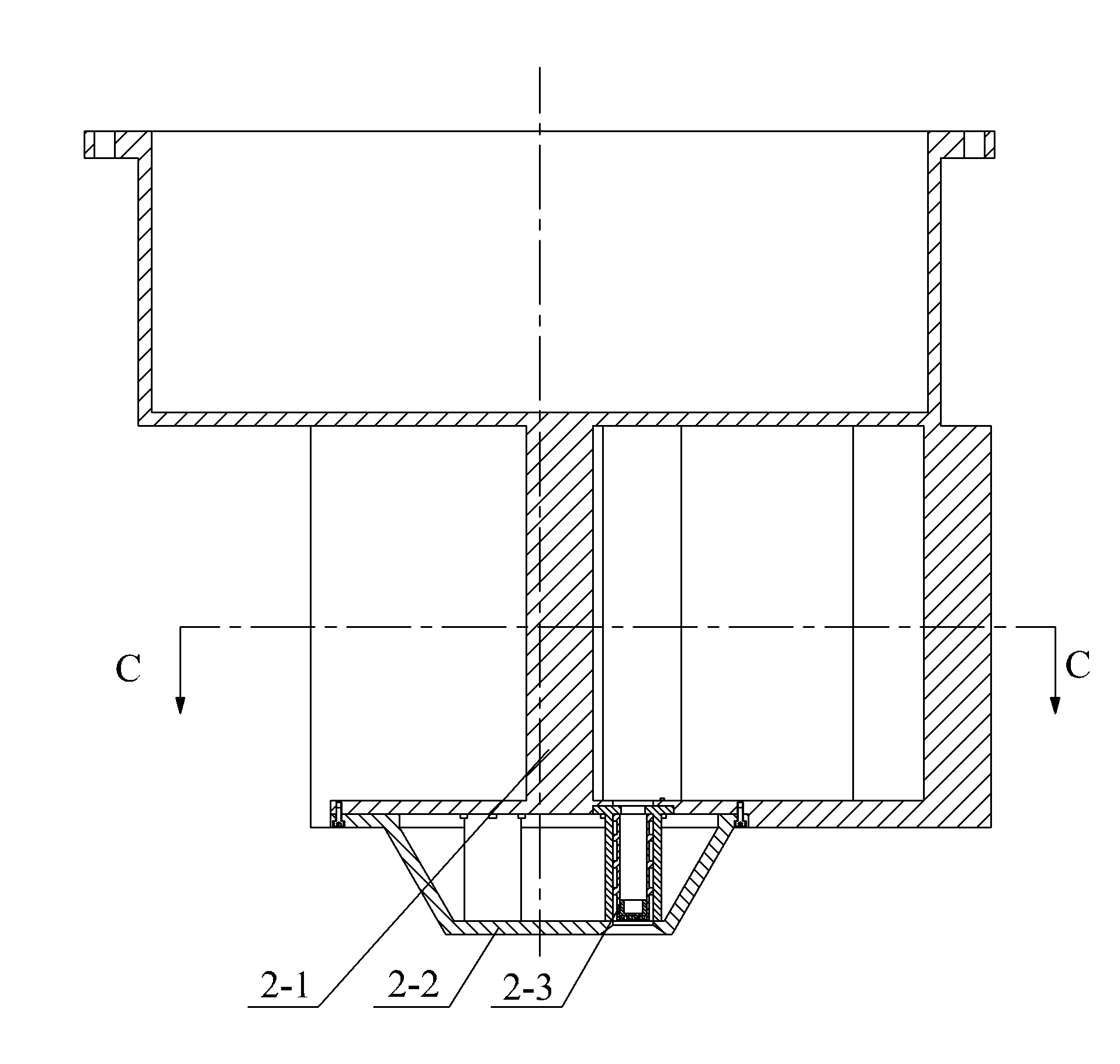

[0007] Specific implementation mode one: as figure 1 As shown, the large-tolerance docking capture device for space-oriented large robotic arm and rendezvous and docking described in this embodiment includes a capture mechanism 1 and an interface mechanism 2, and the capture mechanism 1 includes three fingers 1-1, a first support shell 1 -2. The second supporting shell 1-3, the third supporting shell 1-4, the finger mounting platform 1-5, the ball screw 1-6, the ball nut 1-7, the first mounting platform 1-8, the end Cover 1-9, second installation platform 1-10, first reversing gear 1-11, three connecting joints 1-12, three rotation limit joints 1-13, outer protective shell 1-14, drive assembly 1-15, three capture electrical connection components 1-16, positioning taper groove 1-17, three linear bearing sliders 1-20, three linear bearing guide post supports 1-21 and three linear bearing guide posts 1 -22, the first supporting shell 1-2, the second supporting shell 1-3, and the...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 1 The driving assembly 1-15 of the large-tolerance docking capture device facing the space-oriented large-scale robotic arm and rendezvous and docking described in this embodiment includes a motor power-off brake 1-15-1, a DC brushless motor 1-15-2, a harmonic A wave reducer 1-15-3 and a second reversing gear 1-15-4, the DC brushless motor 1-15-2 is fixedly installed on the second installation platform 1-10, the DC brushless motor 1 The output end of -15-2 is connected to the input end of the harmonic reducer 1-15-3, and the output shaft of the harmonic reducer 1-15-3 is connected to the second reversing gear 1-15-4, so The second reversing gear 1-15-4 meshes with the first reversing gear 1-11. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as figure 1 As shown, the capture mechanism 1 of the large-tolerance docking capture device facing space and rendezvous and docking described in this embodiment also includes a nut limited floating installation spring end cover 1-18 and a nut limited floating installation spring 1-19. The nut limited floating mounting spring 1-19 is set on the rolling nut 1-7, and the nut limited floating mounting spring end cover seals the nut limited floating mounting spring between the rolling nut 1-7 and the inner wall of the finger mounting platform 1-5 between. This embodiment enables the ball nuts 1-7 to have a certain degree of self-alignment and buffering capacity, even in the presence of partial loads and impacts, the ball nuts 1-7 can still be loaded evenly, and will not be damaged due to impacts, increasing Extend the service life of ball nut 1-7. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com