Bus handle with adjustable height

A technology for handlebars and buses, which is applied to vehicle parts, special positions of vehicles, transportation and packaging, etc., can solve the problems of low handlebars and inconvenient gripping beams, etc., and achieves the effect of solving use requirements, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

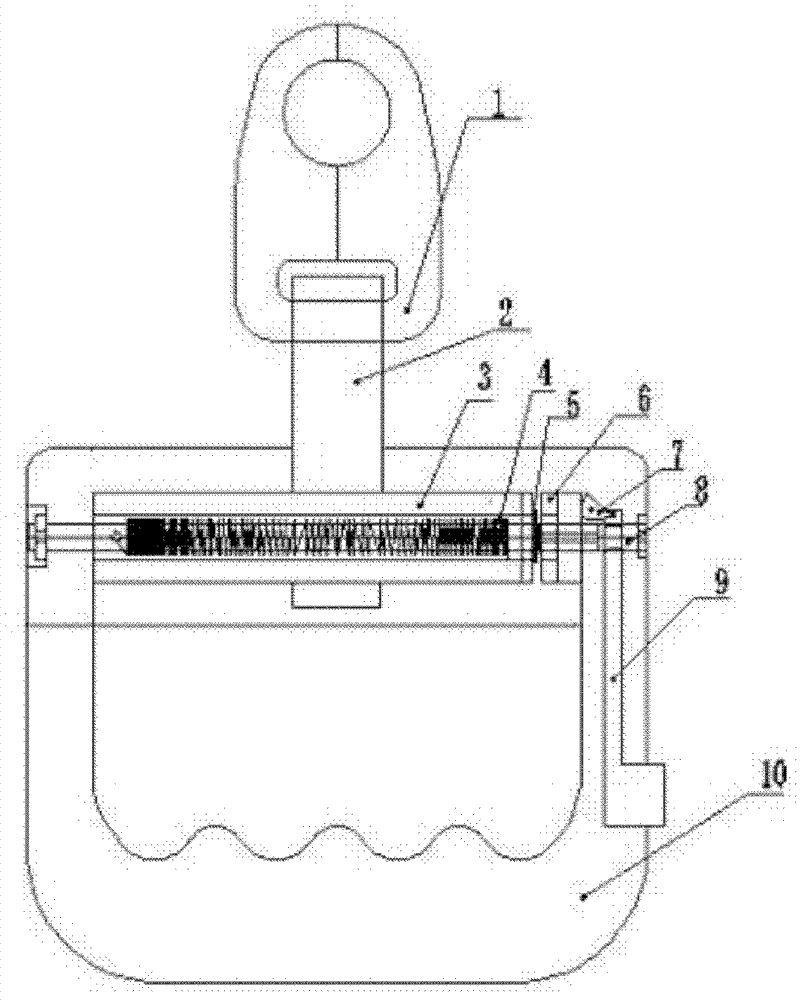

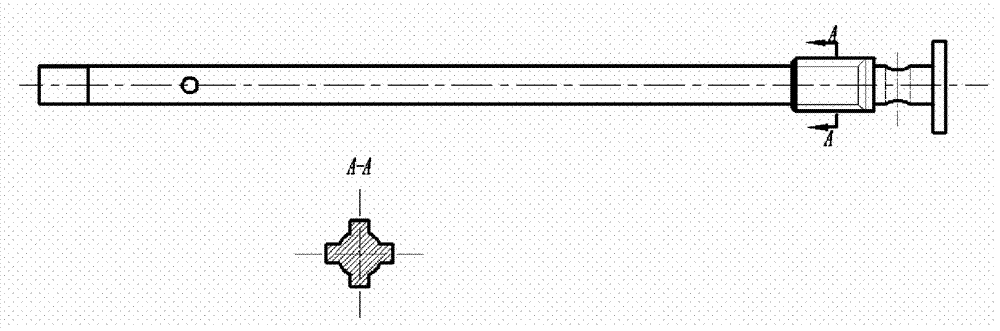

[0015] Such as figure 1 . figure 2 Described, the present invention fixes the handle on the bus beam by the fixing sleeve 1, and when not in use, the cloth tape 2 is wound on the reel 3, and the bus handle is at the maximum height position; When appropriate, hold the handle 10 and pull it downward, the chuck 6 and the reel 3 are in a separated state under the action of the jacking force spring at this time, the reel 3 rotates around the fixed shaft 8, and the cloth tape wrapped on the reel 2 will be pulled out, thereby lowering the height of the bus handle, pushing the lock switch, and the push rod 9 moves upward, driving the camshaft plate 7 to rotate counterclockwise along the pin shaft, pushing the chuck 6 to move to the left, and the chuck 6 and The reel 3 is engaged, the reel 3 can no longer rotate around the fixed shaft 8, and the height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com