Roller slope control device

A technology for controlling device and wheel inclination, which is applied in transportation and packaging, winding strips, thin material processing, etc., and can solve problems affecting the processing of working links, material belt damage, uneven pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

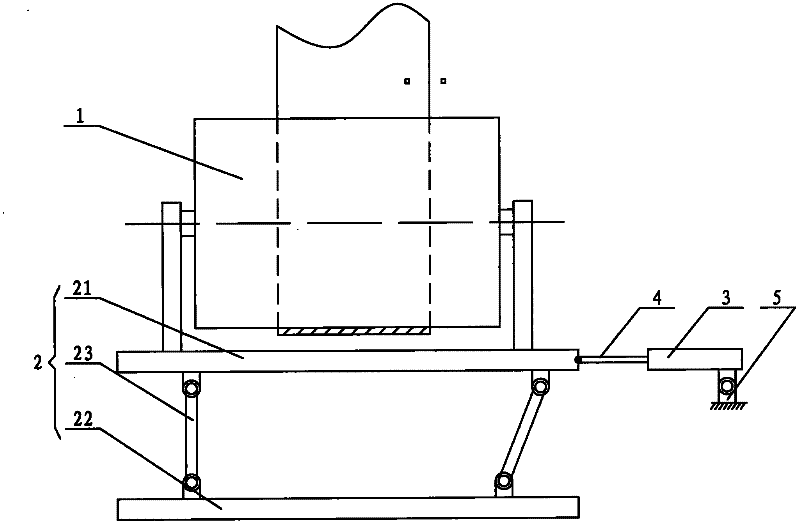

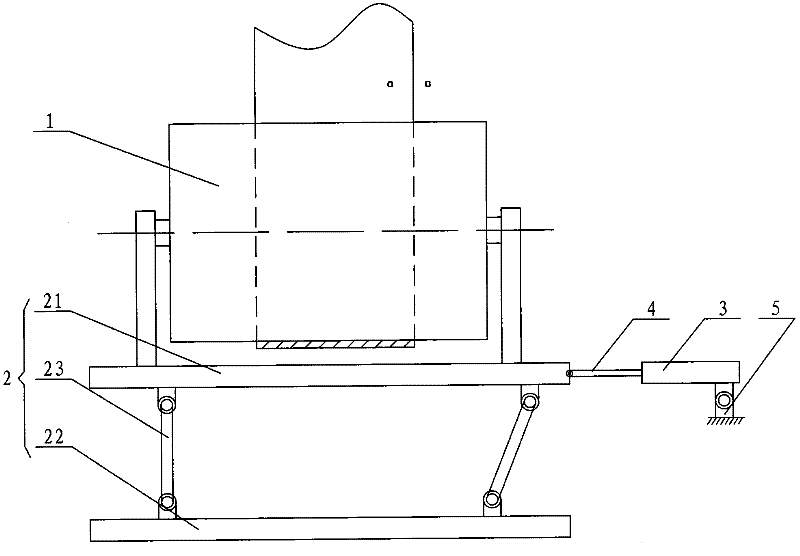

[0014] Such as figure 1 As shown, the roller inclination control device according to the present invention mainly includes a roller 1, an inclination control mechanism 2 and a driving cylinder 3. However, the roller 1 plays a supporting role on the material belt, and the roller shafts at the centers of the two ends of the roller 1 are respectively installed on the upper bracket of the tilt control mechanism 2, and the bracket is installed upright on the upper surface of the tilt control structure 2 and For fixing, the movable end of the tilt control mechanism 2 is affixed to the piston rod 4 of the drive cylinder 3, and the position of the drive cylinder 3 itself is fixed; the tilt control mechanism 2 includes an upper panel 21 and a lower base plate 22, and the lower base plate 22 is fixed in position, and the upper panel 21 is a movable plate. Two support plates 23 are supported between the upper panel 21 and the lower base plate 22. Hinged, the upper panel 21 , the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com