A quick-replacement torque release device for steel wire ropes

A release device and wire rope technology, which is applied in the field of steel wire rope replacement devices for coal mine hoists, can solve problems such as low efficiency, unsatisfactory reliability and safety, and no effective guarantee for the personal safety of operators, and achieve simple overall structure and easy operation. Easy to use and disassemble, ensuring personal safety and property damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

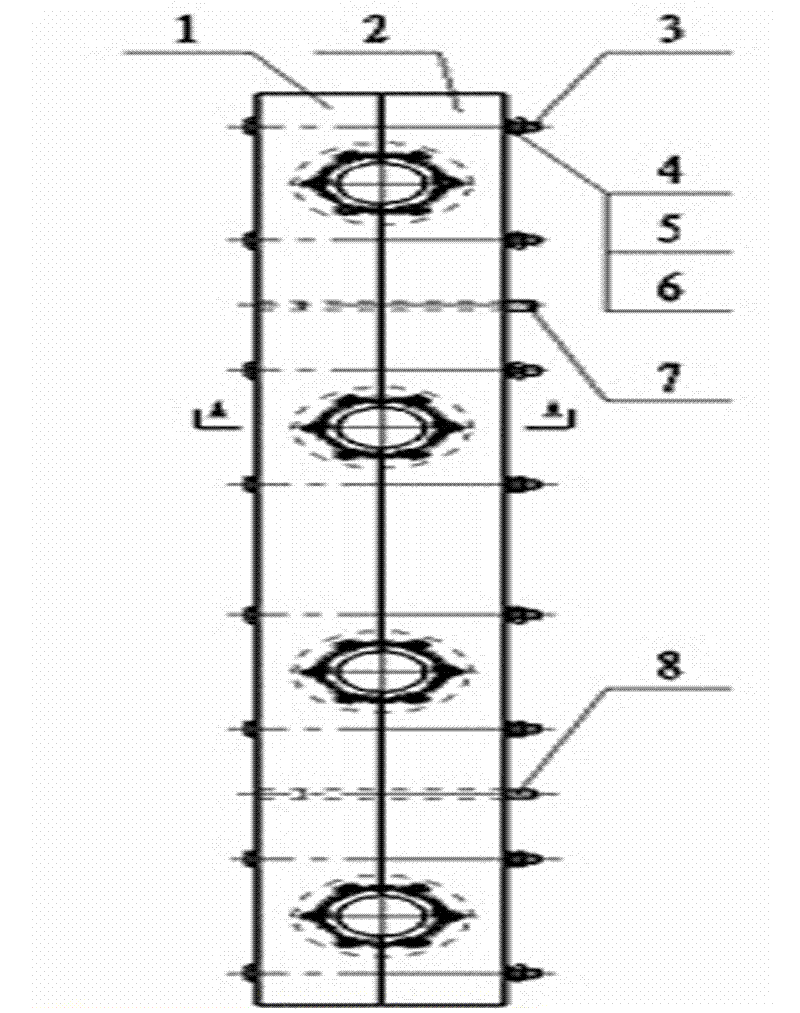

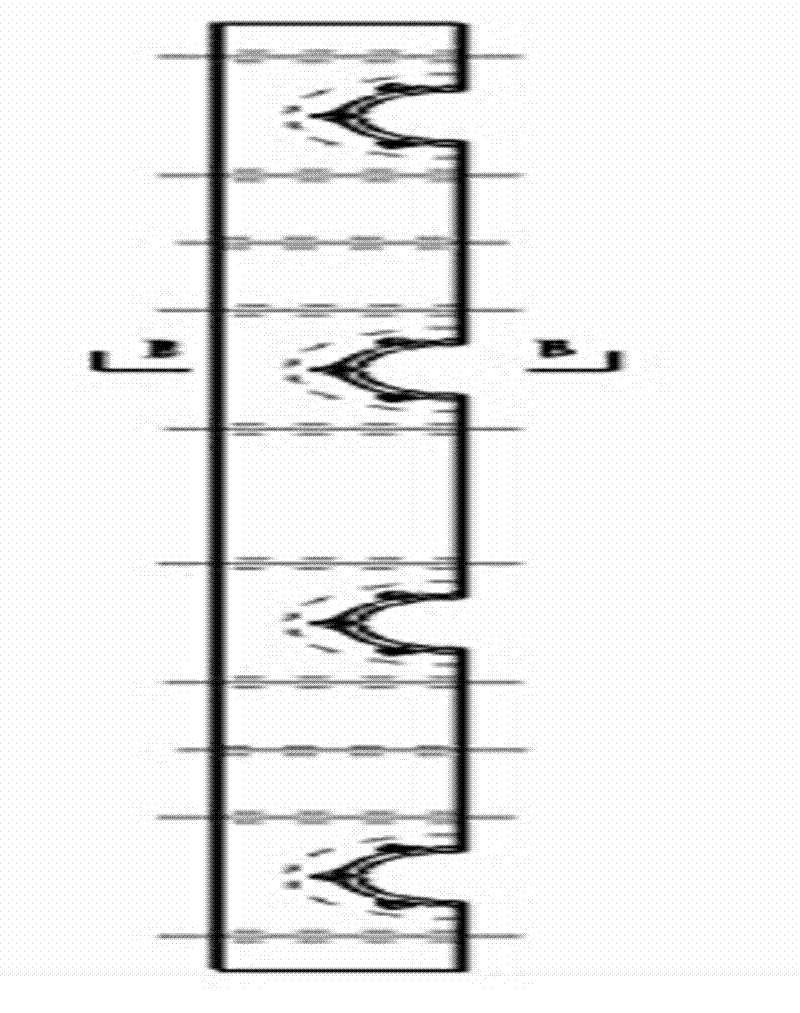

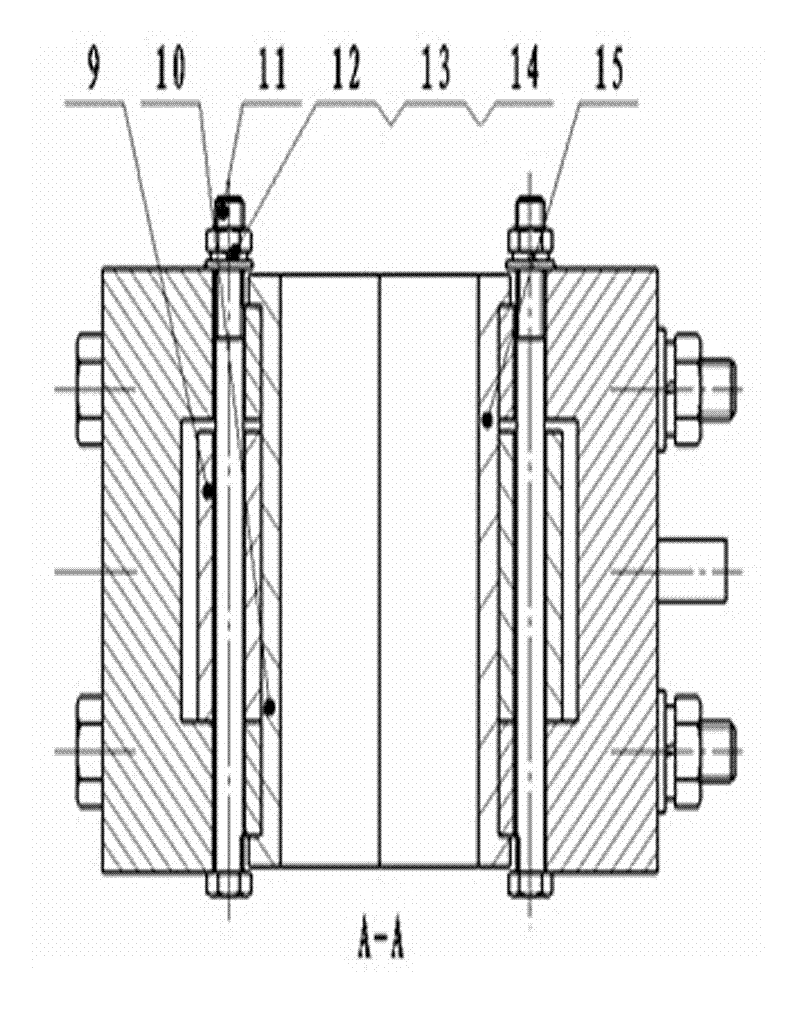

[0014] The technical scheme of a kind of steel wire rope fast replacement torsion release device provided by the present invention is further described below in conjunction with the accompanying drawings:

[0015] Such as figure 1 and figure 2 As shown, the concrete technical scheme of implementing a kind of steel wire rope fast replacement torque release device of the present invention is to be respectively provided with an annular groove inside the middle part of the 4 holes of the left card 1 and the right card 2, respectively set in the grooves There are three cylindrical rollers 9 at an angle of 60°, and hexagon head bolts 11 are provided to connect the cylindrical rollers 9 with the left board 1 and the right board 2 respectively in the form of penetration. The inner side of the hole of the right plate card 2 is respectively provided with a left half sleeve 10 and a right half sleeve 15. Wherein the cylindrical roller 9 has reduced the frictional force generated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com