Polyamideimide cured epoxy resin composite material and preparation method thereof

A technology of polyamide-imide and epoxy resin, which is applied in the field of polyamide-imide (PAI)-cured epoxy resin composite materials and its preparation, and can solve problems such as poor compatibility, low heat resistance, and easy oxidation. problems, to achieve the effect of moderate crosslinking degree, avoiding insufficient toughness and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

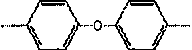

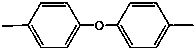

Image

Examples

Embodiment 1

[0042] Dissolve 100g of tetraglycidylamine epoxy resin (epoxy value 0.80eq / 100g) in an appropriate amount of N,N'-dimethylacetamide, add 283g of PAI-2 curing agent after fully dissolved, put Put it into a blast oven, pre-cure at 165°C for 1 hour, and cure at 235°C for 3 hours. The tensile strength of the obtained cured product is 113MPa, the initial thermal decomposition temperature is 401°C, the residual carbon is 43.1%, and the limiting oxygen index is 34.7%.

Embodiment 2

[0044] Dissolve 100g of tetraglycidylamine epoxy resin (epoxy value 0.80eq / 100g) in an appropriate amount of N,N'-dimethylacetamide, add 242g of PAI-1 curing agent after fully dissolved, put Put it into a blast oven, pre-cure at 165°C for 1 hour, and cure at 250°C for 3 hours. The tensile strength of the obtained cured product is 106MPa, the initial thermal decomposition temperature is 398°C, the residual carbon is 41.7%, and the limiting oxygen index is 34.2%.

Embodiment 3

[0046] Dissolve 100g of bisphenol A epoxy resin (epoxy value 0.44eq / 100g) in an appropriate amount of N,N'-dimethylacetamide, add 156g of PAI-3 curing agent after fully dissolved, put Pre-cured at 165°C for 1 hour and cured at 224°C for 3 hours in a blast oven. The tensile strength of the cured product was 101MPa, the initial thermal decomposition temperature was 393°C, the residual carbon was 39.9%, and the limiting oxygen index was 33.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com