Dispersed fiber gathering and distributing device

A technology of distributing device and fiber, applied in fiber processing, textile and papermaking, floc filling, etc., can solve the problems of affecting the workshop environment, slow filling of floc fibers, and insufficient filling of finished thread floc fibers, etc. The effect of plumpness and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

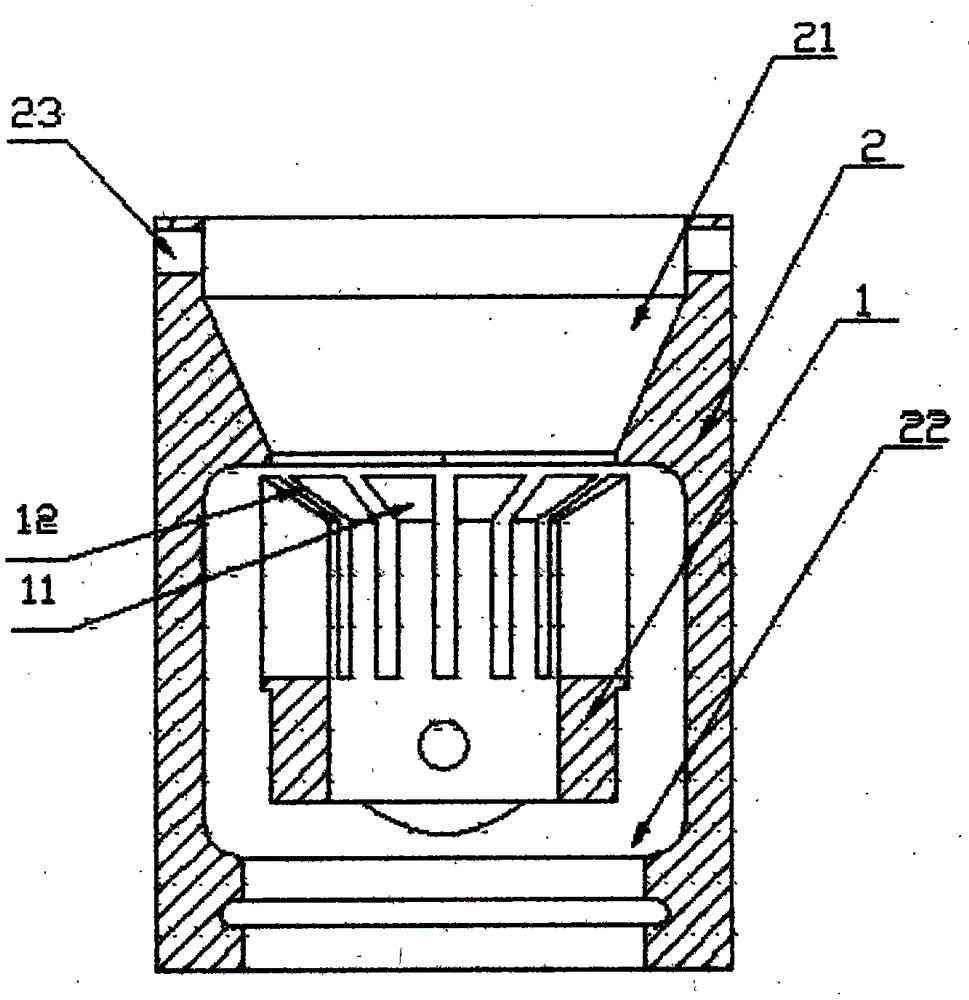

[0010] Embodiment: A device for gathering and distributing scattered fibers, including a fiber distributor 1, based on the use direction, the inside of the fiber distributor 1 is provided with a funnel through hole 11 whose upper end diameter is larger than the lower end diameter, and the axial side wall of the fiber distributor 1 Spaced axial opening grooves 12 are arranged on the top, and a diffuse fiber collector 2 is also included. The upper section of the diffuse fiber collector 2 is provided with a funnel hole 21 whose upper diameter is greater than that of the lower end, and the lower section of the diffuse fiber collector 2 is provided with a The axial through hole 22 connected to the funnel hole 21, the fiber distributor 1 can be fixedly inserted into the axial through hole 22 in the lower section of the diffuse fiber collector 2, and the upper end surface of the fiber distributor 1 just covers the diffuse fiber collector. The lower end of the funnel hole 21 of 2, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com