Longitudinal guide rail installation method and device

A technology of longitudinal guide rail and installation method, which is applied in the direction of ship lifting device, vertical lifting ship machinery, construction, etc., can solve the problems of narrow installation space, small structural rigidity, long construction period, etc., to meet the requirements of high precision and facilitate installation and adjustment. , to solve the effect of small stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

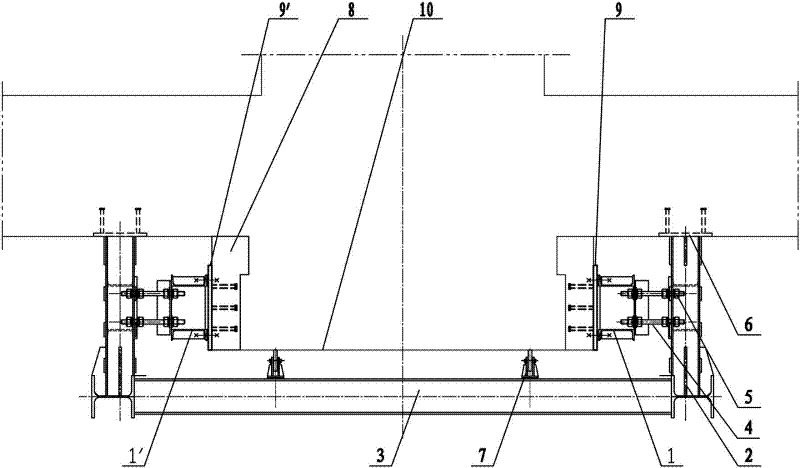

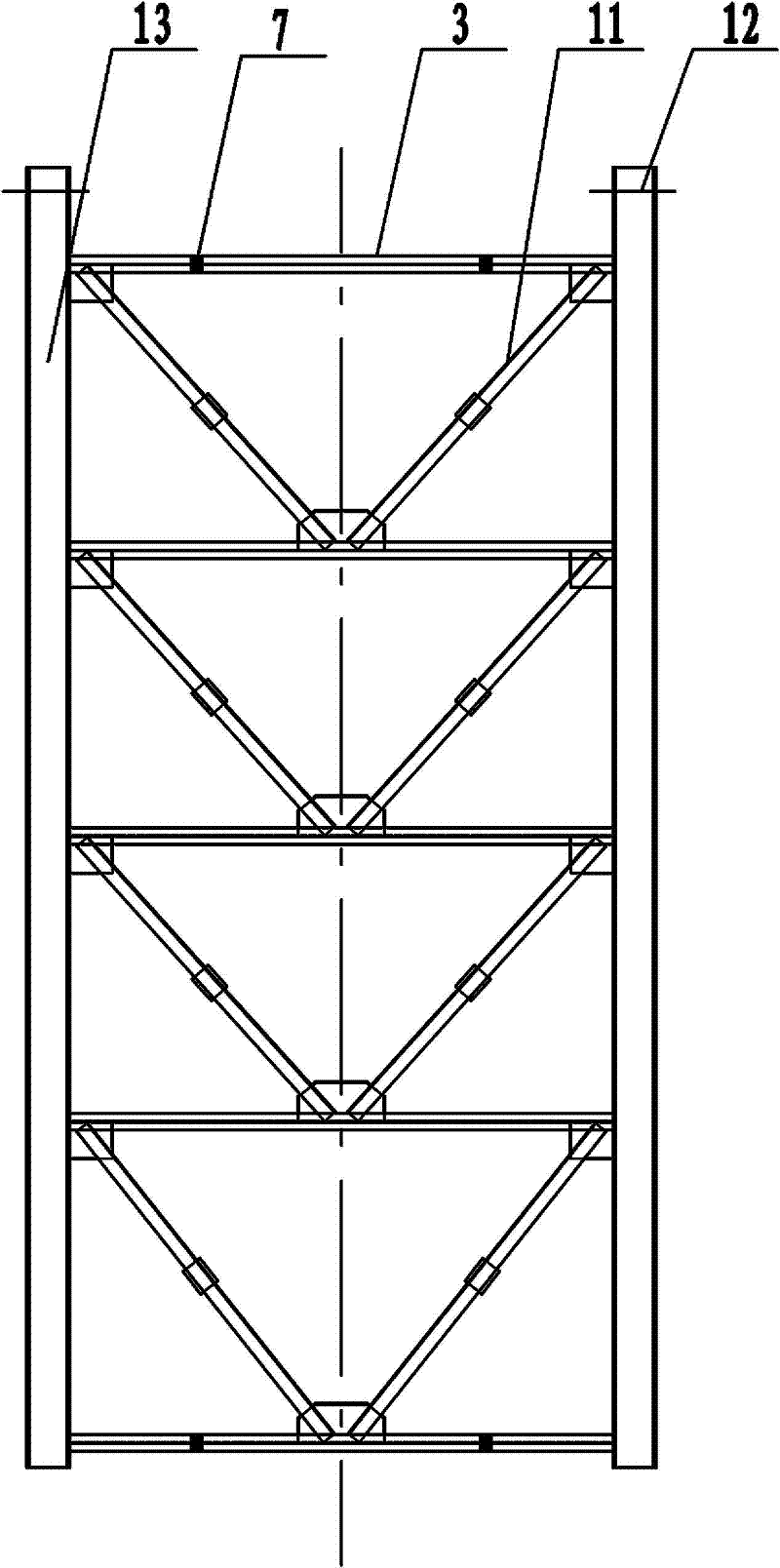

[0027] A method for installing a longitudinal guide rail, comprising the following steps:

[0028] 1) Concrete convex wall 10 is poured, and anchor plate embedded parts 6 are pre-embedded on both sides of poured concrete convex wall 10, which are used for the fixed installation of "U"-shaped steel beam frame;

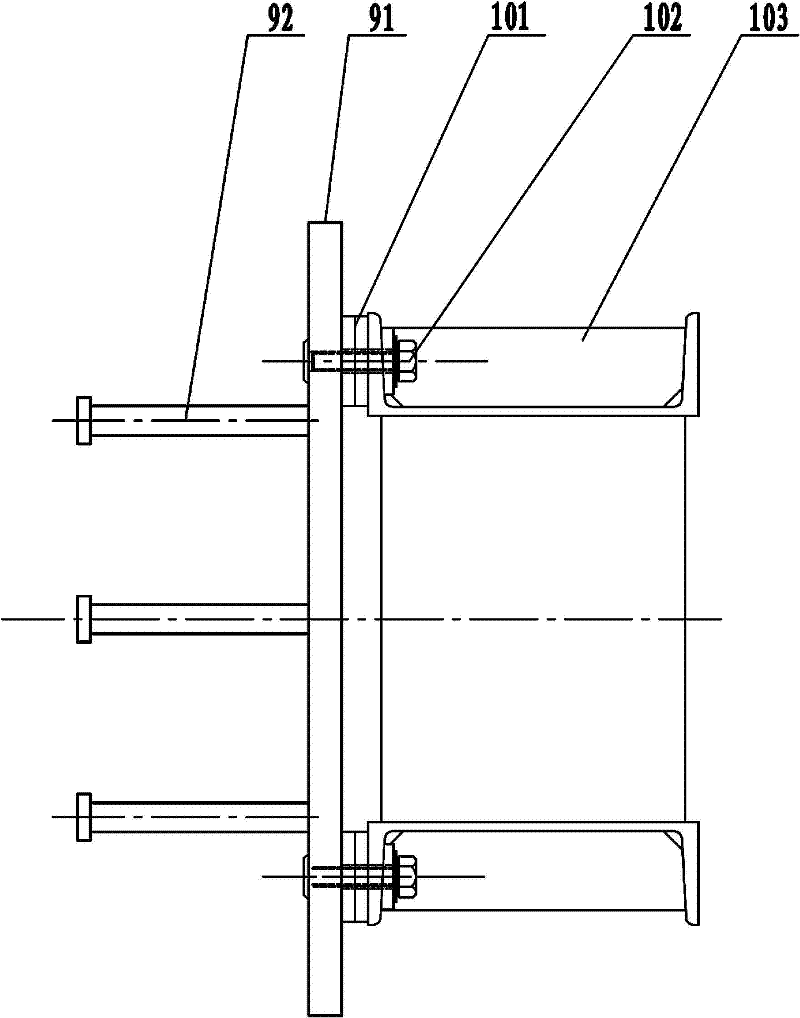

[0029] 2) Hoist the "U"-shaped steel beam frame and connect it with the embedded part 6 of the anchor plate, and connect the built-in steel frame 1,1' and the longitudinal guide rails 9,9' through the fixing bolts 102 on the pre-assembled platform; specifically, the built-in steel frame The auxiliary steel frame 103 in 1, 1' is connected with the guide rail working panel 91 in the longitudinal guide rails 9, 9' through fixing bolts 102, in order to ensure the accuracy, there is also a spacer between the auxiliary steel frame 103 and the guide rail working panel 91 101, the mating surface of the spacer 101 and the guide rail working panel 91 is machined to improve flatn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com