Limiting device and method of lifting and pushing mechanism of mine excavator

A technology for excavators and mines, which is applied in the field of limit devices, can solve the problems that affect the life of equipment mechanisms, only have mechanical baffles, and the accuracy cannot meet the requirements, etc., and achieve the effect of meeting urgent needs, accurate and flexible setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the drawings.

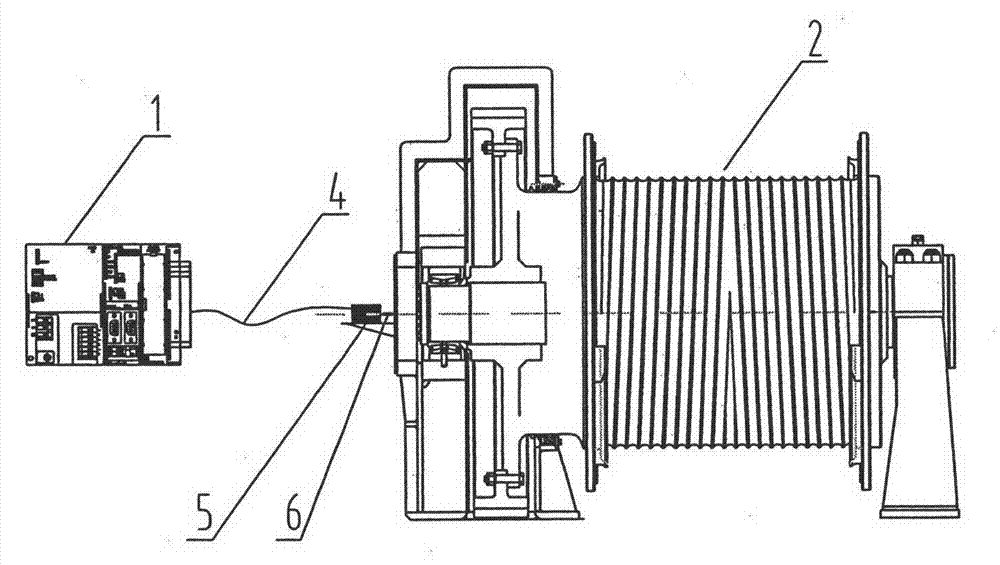

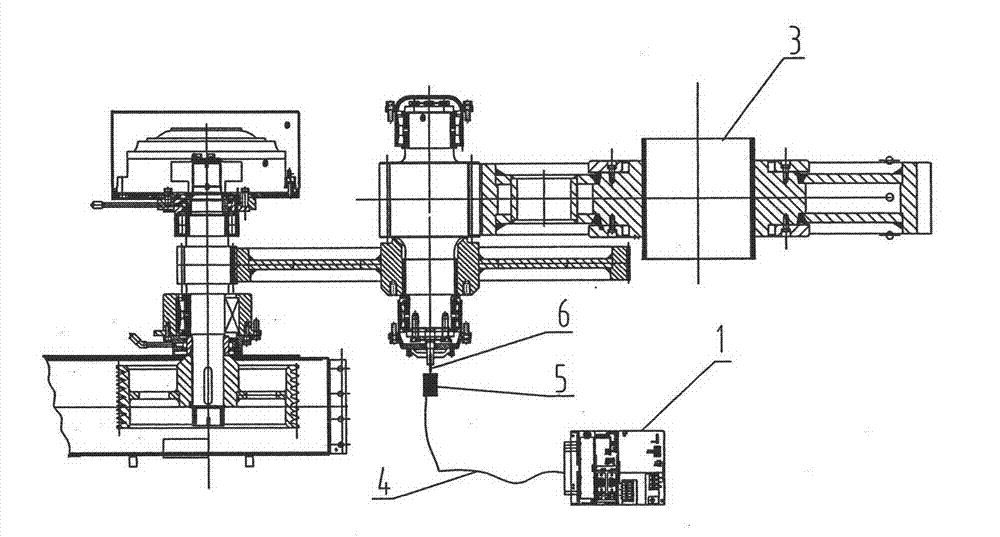

[0019] Such as figure 1 with figure 2 As shown, the installation diagram of lifting and pushing absolute encoder. The limit device of the lifting and pushing mechanism of the mining excavator, including the programmable controller PLC 1, the human-machine interface HMI, the lifting and pushing absolute value encoder; the lifting absolute value encoder 5 passes through the flexible shaft 6 is connected to the reel 2 of the lifting mechanism; the pushing absolute value encoder 5 is connected to the shaft of the reducer 3 of the pushing mechanism through the flexible shaft 6; the signal of the lifting and pushing absolute value encoder 5 Connect to the position input module of the programmable controller PLC through the shielded cable 4.

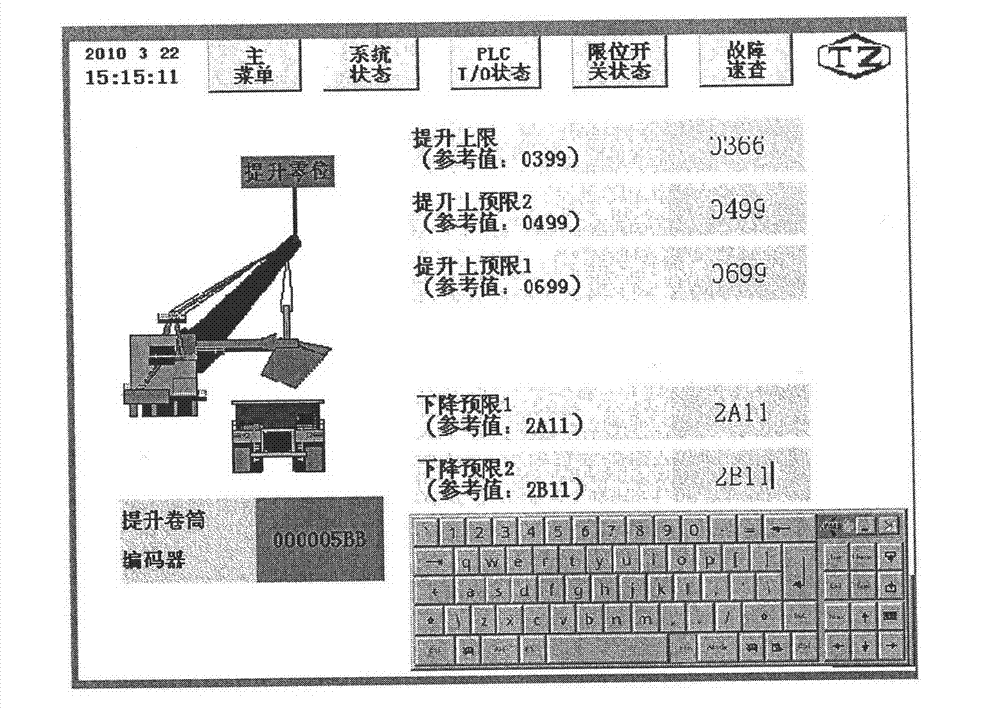

[0020] The limit method of the lifting and pushing mechanism of the mining excavator uses the programmable controller PLC 1, the man-machine interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com