Lining method for tunnel emergency turnout strips and tunnel-lining trolley

A technology for lining trolleys and trolleys, which is applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems of difficulty in guaranteeing lining accuracy, large labor force, and low efficiency, and achieve the goal of reducing labor intensity, shortening construction period, and improving lining efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0026] The lining method of tunnel emergency avoidance belt of the present invention comprises the steps:

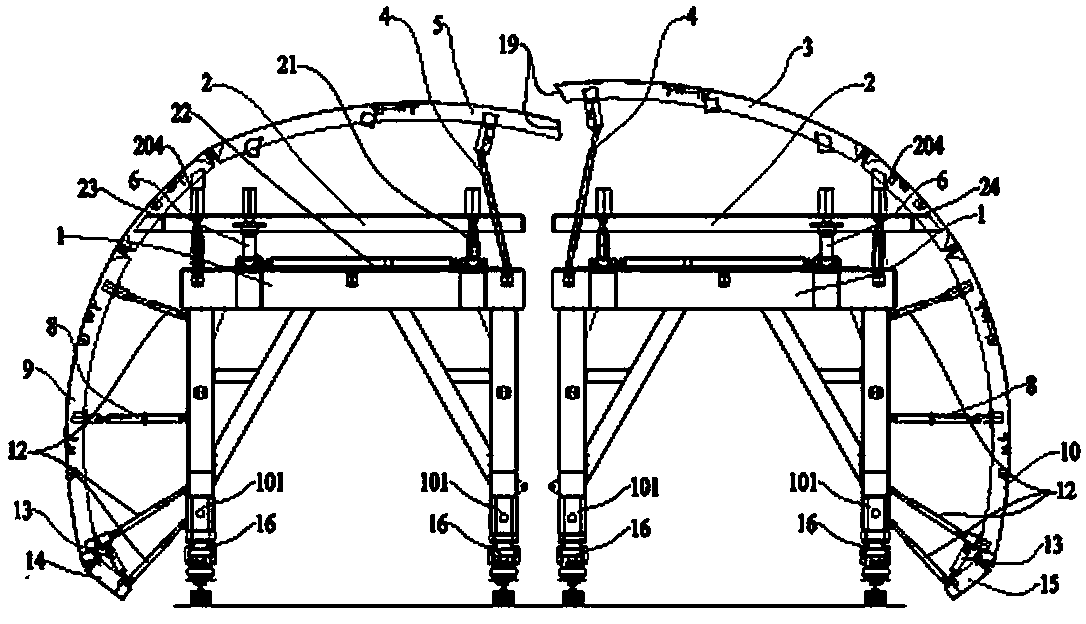

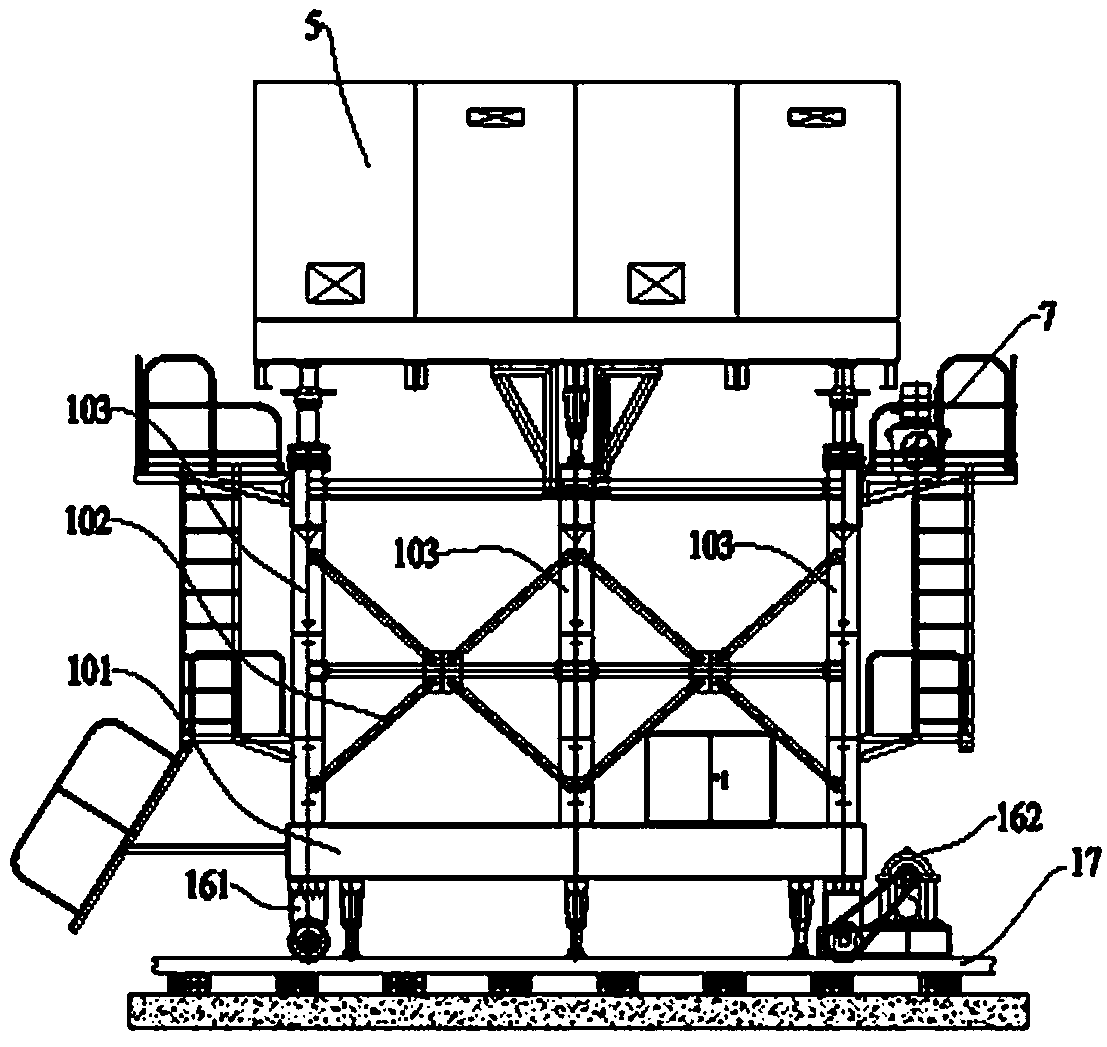

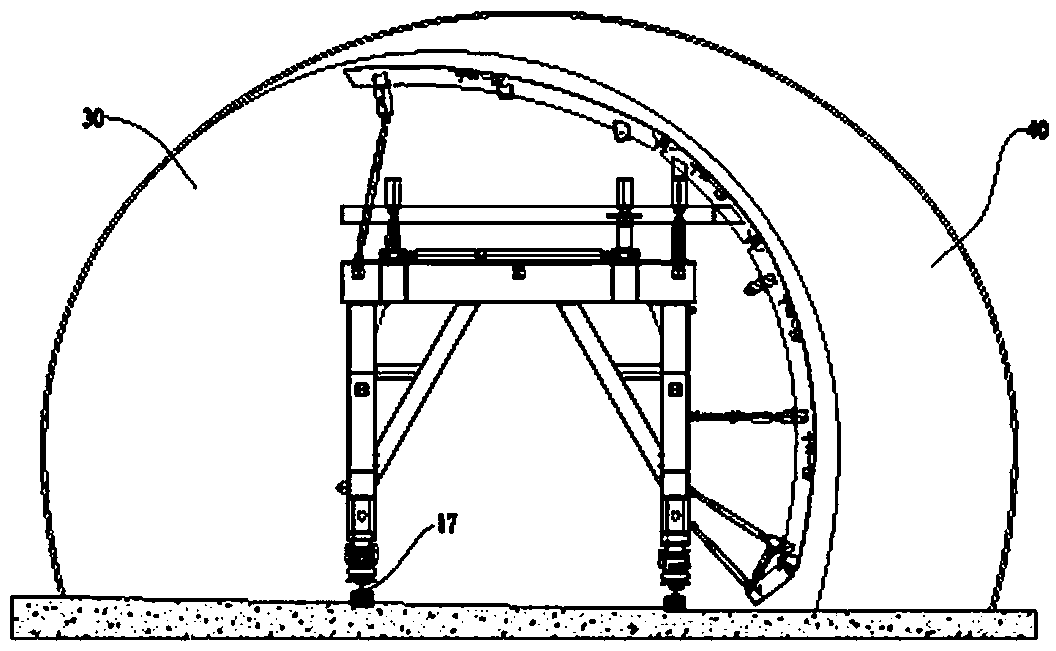

[0027] (1) Refer to figure 1 and image 3 , decompose the tunnel lining trolley into two left and right tunnel lining trolleys with independent running mechanisms, and the left trolley includes the top formwork for installation 5, the left side formwork 9, running mechanism 16, door frame 1, bracket 2, bracket support jack 4 and side jack 12. The right trolley includes the top mold frame for installation 3, the right side formwork 10, traveling mechanism 16, door frame 1, bracket 2, bracket support jack 4 and side jack 12. The running mechanism of the left and right trolleys can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com