Intelligent lining trolley for tunnel

A lining trolley, intelligent technology, applied in the direction of tunnel lining, tunnel, wellbore lining, etc., can solve the problems of increasing the risk factor, generating cracks, falling off fragments, etc., to achieve the effect of improving the breadth of application, reducing manufacturing costs, and improving lining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

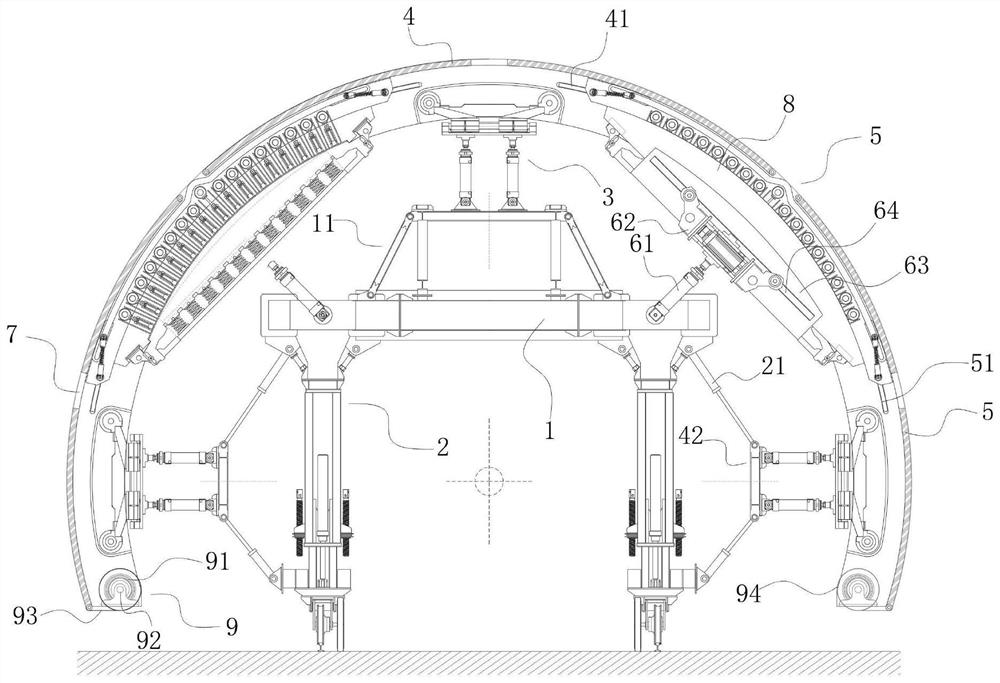

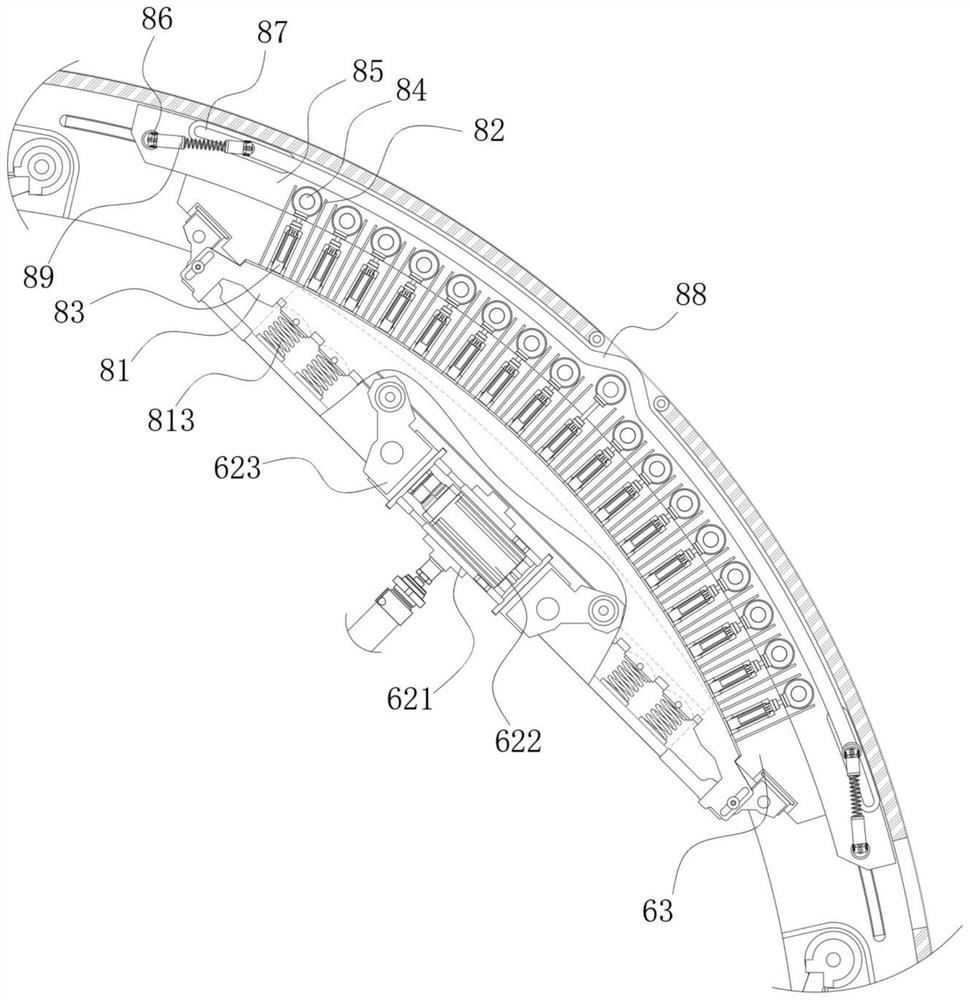

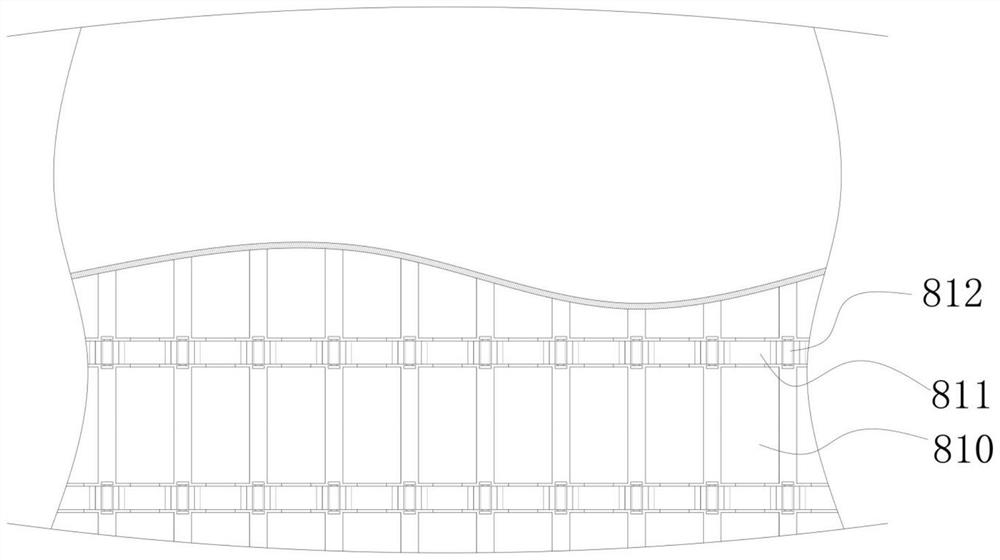

[0035] refer to Figure 1-5 , the present invention provides a technical solution: a tunnel intelligent lining trolley, which includes:

[0036] Crossbeam frame 1, multiple groups are arranged parallel to the front and rear of the same level, and are fixed. A trapezoidal support frame 11 is installed in the center of the upper side of each group of horizontal frame 1, and a vertically arranged liftable walking frame 2 is installed on the lower side near the left and right ends. The left and right ends are symmetrically installed with an upwardly inclined 45° mold expanding device 6, and the outer boundary surface of the mold expanding device 6 is an arc-shaped curved surface, and the outer side of the liftable walking frame 2 is hinged with a lifting rod 21 at the upper and lower ends;

[0037] The hydraulic jacking frame 3 is configured in multiple groups, and is installed vertically on the upper end of the corresponding trapezoidal support frame 11, and installed horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com