A device for separating projectile and projectile support

A separation device, projectile support technology, applied in the direction of projectiles, offensive equipment, weapon types, etc., can solve the problems of low connection strength, debris hitting the target board, and the interceptor can only be used one time, to achieve the connection High strength and impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

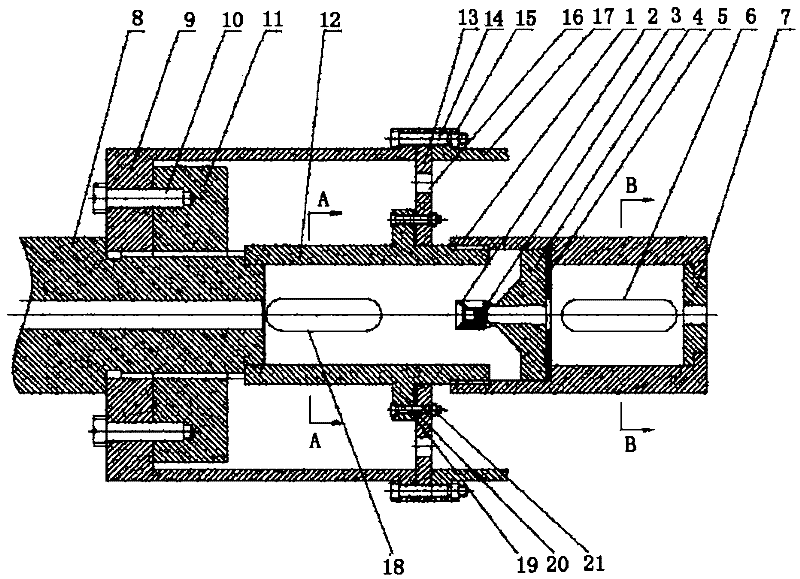

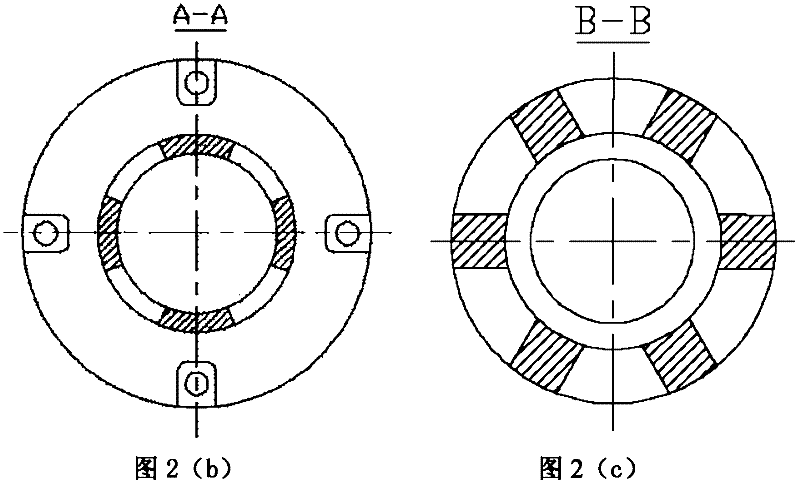

[0017] Referring to Fig. 2, Fig. 2 is the structure schematic diagram of the moment of separation of the projectile and cartridge separating device of the present invention, the shunt chamber 9 of the light gas gun body is arranged on the gun barrel 8, and the shunt chamber 9 of the light gas gun body is connected with a flange by a screw 10 Disc 11 is provided with guide chamber 12 and separation chamber 1 at the outlet of gun barrel 8. The guide chamber 12 is provided with an elliptical air release port 18, the separation chamber 1 is provided with an oval air release port 6, and the guide chamber 12 is connected with a support plate. 13. The support plate 13 is connected with the split chamber 9 of the light gas gun body and the test chamber 17 of the light gas gun body by screws, and the support plate 13 has a gas leak port 16 .

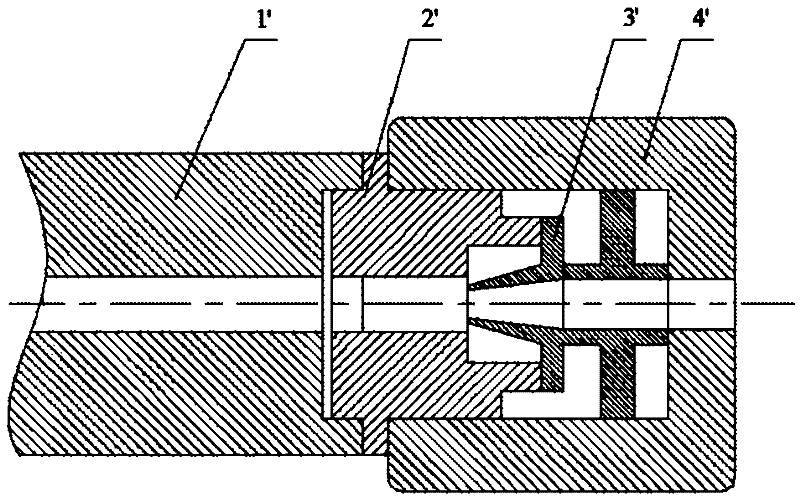

[0018] One end of the separation chamber 1 is threadedly connected to the guide chamber 12 , and a separation block 4 , a buffer plate 5 and a bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com