Inductive sliding micrometer

A micrometer and inductive technology, which is applied in the direction of measuring devices, instruments, and electrical devices, can solve the problems of greater influence on instrument stability and measurement accuracy, restrictions on sensitivity and measurement accuracy, and low measurement accuracy. Achieve fast positioning, high sensitivity, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

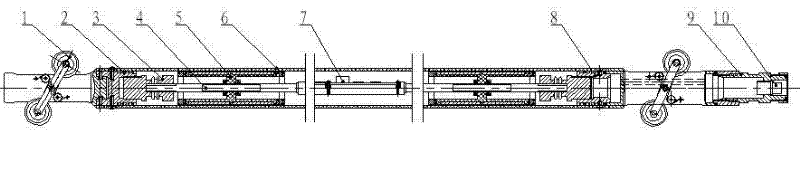

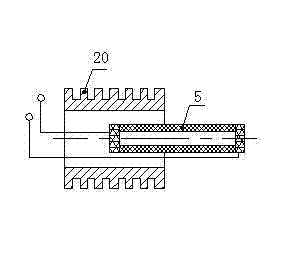

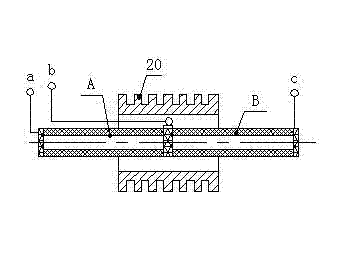

[0032] Such as figure 1 As shown, an inductive sliding micrometer includes a housing 6, an upper seal seat 8, a lower seal seat 2, a guide roller component 1, a cable outlet seat 9, a central support rod 4, an inductance coil 5, an elastic connecting rod 3, Measurement and control circuit board 7. The central support rod 4 is a long rod located in the shell 6, and the two ends of the central support rod 4 are covered with elastic connecting rods 3, and a group of inductance coils 5 are respectively installed on the central support rod 4 near the two ends. , a total of two groups of inductance coils 5, each group of inductance coils 5 is composed of two small coils wound on the same bobbin in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com