A Method for Measuring Three Components of Magnetic Induction Intensity by Optical Pump Three-coil Compensation Method

A technology of magnetic induction intensity and compensation method, which is used in radio wave measurement systems, measurement devices, and electrical/magnetic exploration, etc., to achieve the effects of convenient operation, flexible use and simple structure combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

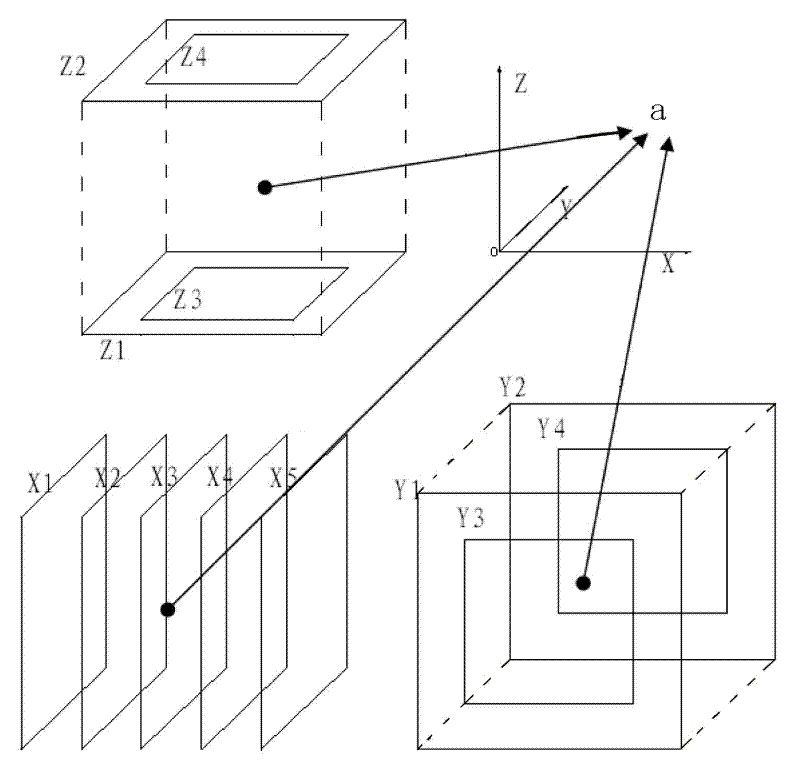

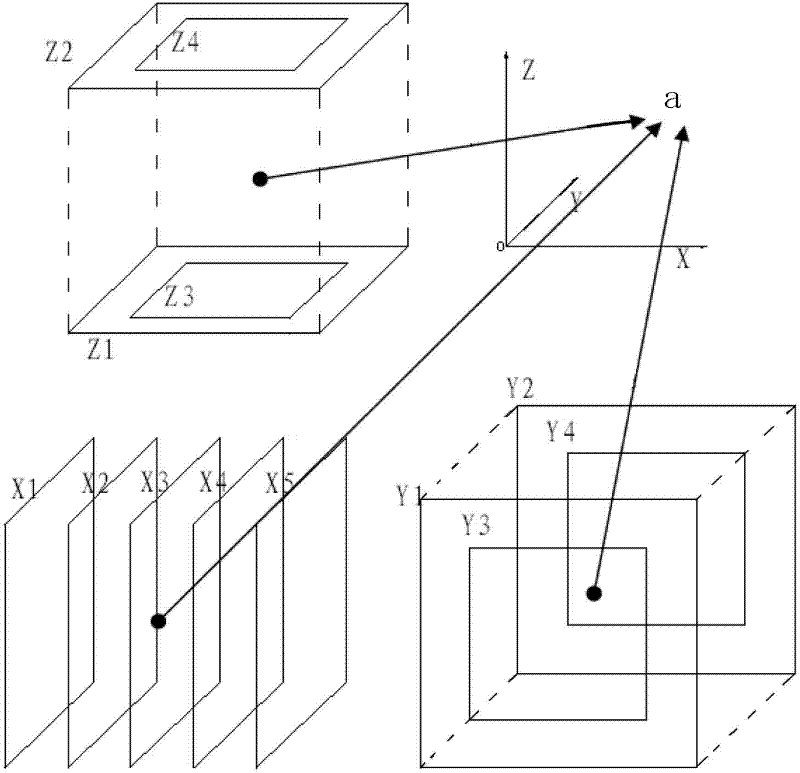

[0013] The invention is mainly composed of a three-coil compensation system and an optical pump system. The optical pump is placed in the uniformity of the three-coil compensation system

[0014] in the district. A three-coil compensation system is used to cancel two components, and the output of the optical pump is used to measure the other component.

[0015] The measuring process of the present invention is as follows:

[0016] (1) Earth magnetic field x component compensation: place the optical pump in the uniform area of the compensation coil, adjust the current of the coil in the x direction, since the output of the optical pump = , when the output of the optical pump is minimum, it indicates that the x component compensation is completed;

[0017] (2) Compensation of the y component of the geomagnetic field: place the optical pump in the uniform area of the compensation coil, and adjust the current of the coil in the y direction. Since the output of the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com