Stator-rotor structure with replaceable crushing gear rings for high shearing equipment

A high-shear, stator-rotor technology, applied in the manufacture of the stator/rotor body, etc., can solve the problems such as the number of teeth and the gap between the rack and rack cannot be adjusted, the flow of energy materials is not smooth, the size of the stator and rotor is large, and the crushing effect is improved. , low cost of use, and optimized material flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

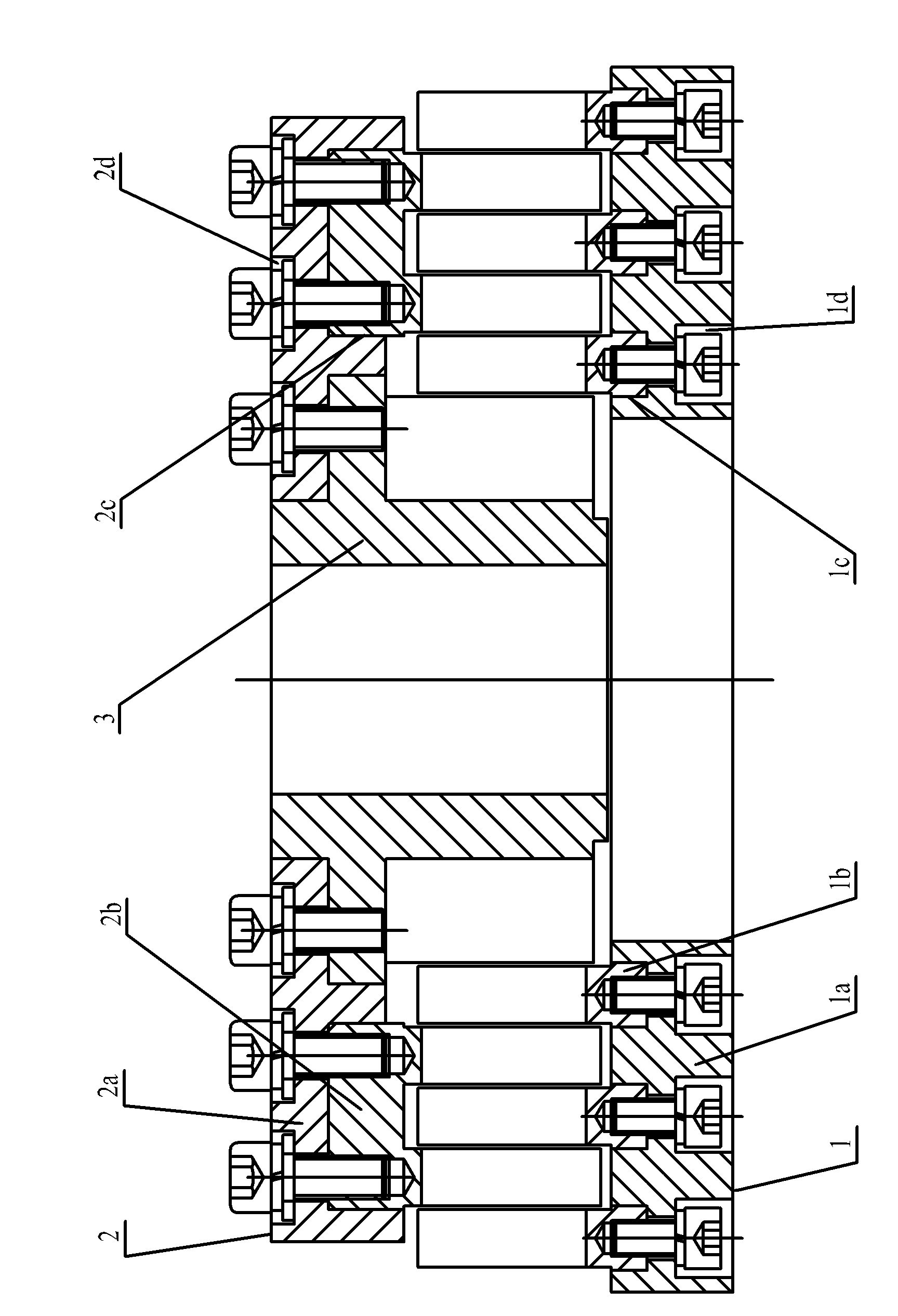

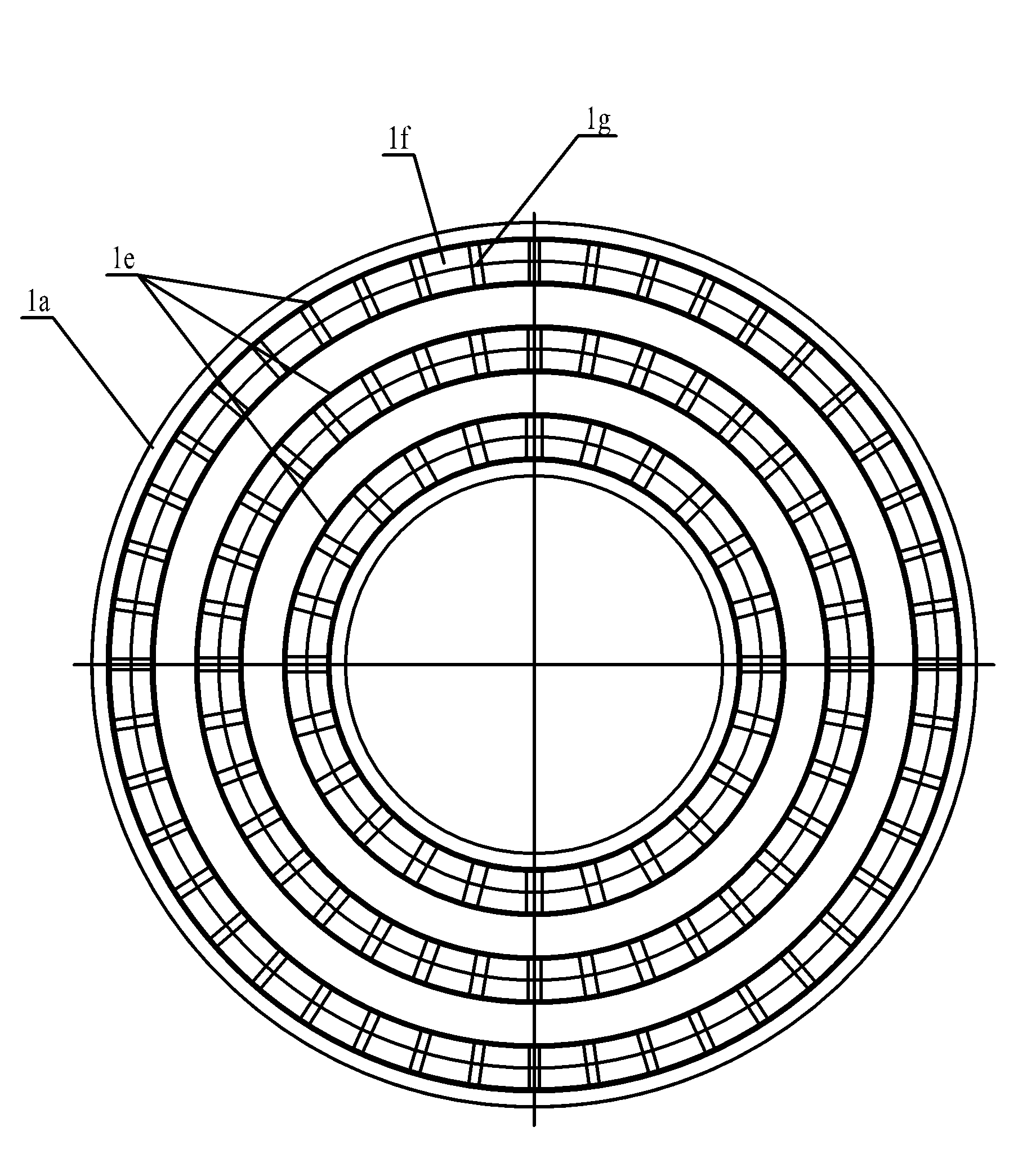

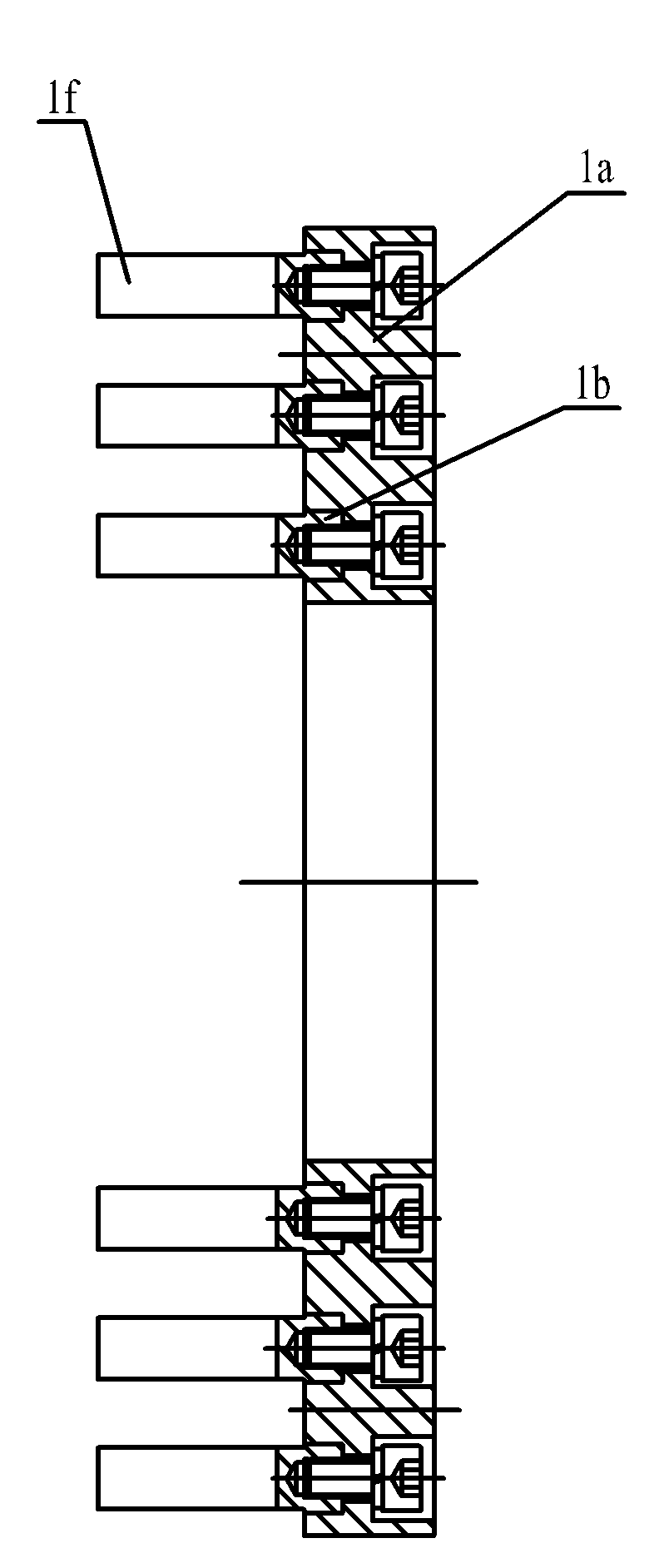

[0024] As shown in the figure, the replaceable stator-rotor structure of the crushing ring gear in the embodiment mainly includes two parts: a stator 1 and a rotor 2 . The stator 1 is mainly composed of a stator base 1a and a stator crushing ring gear 1b. The stator base 1a is provided with three concentric annular stator positioning grooves 1c, and a detachable stator crushing groove 1c is embedded in each annular stator positioning groove 1c. Ring gear 1b; the bottom of each annular stator positioning groove 1c is provided with mounting holes 1d uniformly distributed along its circumference, and the stator crushing ring gear 1b is fixed on the stator base 1a by fastening screws passing through the mounting holes 1d; in the embodiment The stator crushing ring gear 1b is provided with a layer of stator crushing gear ring 1e, and the stator crushing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com