A method for distributing simulated ceramic tiles with internal thin line texture and ceramic tiles

A technology of texture and thin lines, which is applied to the cloth method of simulated tiles and the field of tiles. It can solve the problems of poor controllability of texture position and size, mixing materials, etc., and achieve the effect of improving the degree of simulation, flexible size setting, and ensuring continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

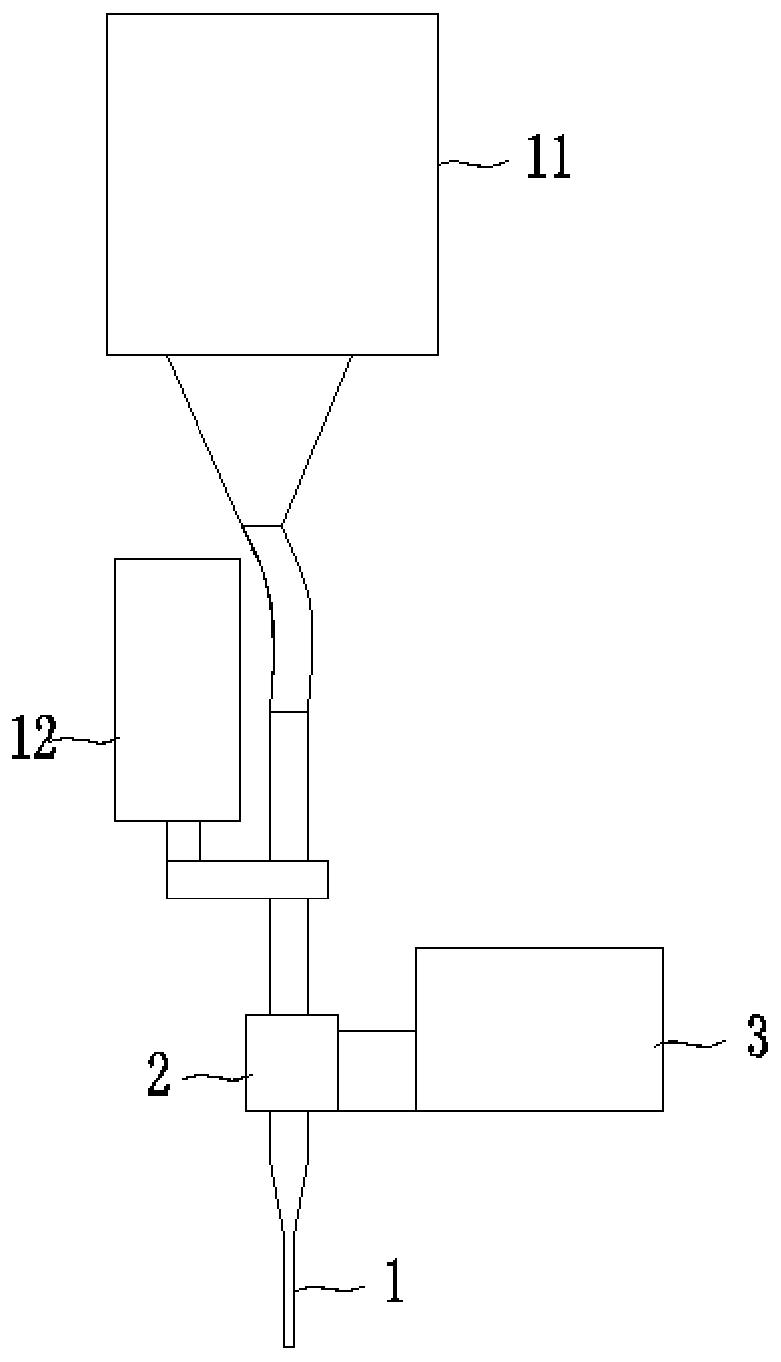

[0060] A method for distributing simulated ceramic tiles with internal thin-line textures, comprising steps (1) to (4), and the details are as follows.

[0061] (1) The basic powder is distributed on the conveyor belt to obtain the blank.

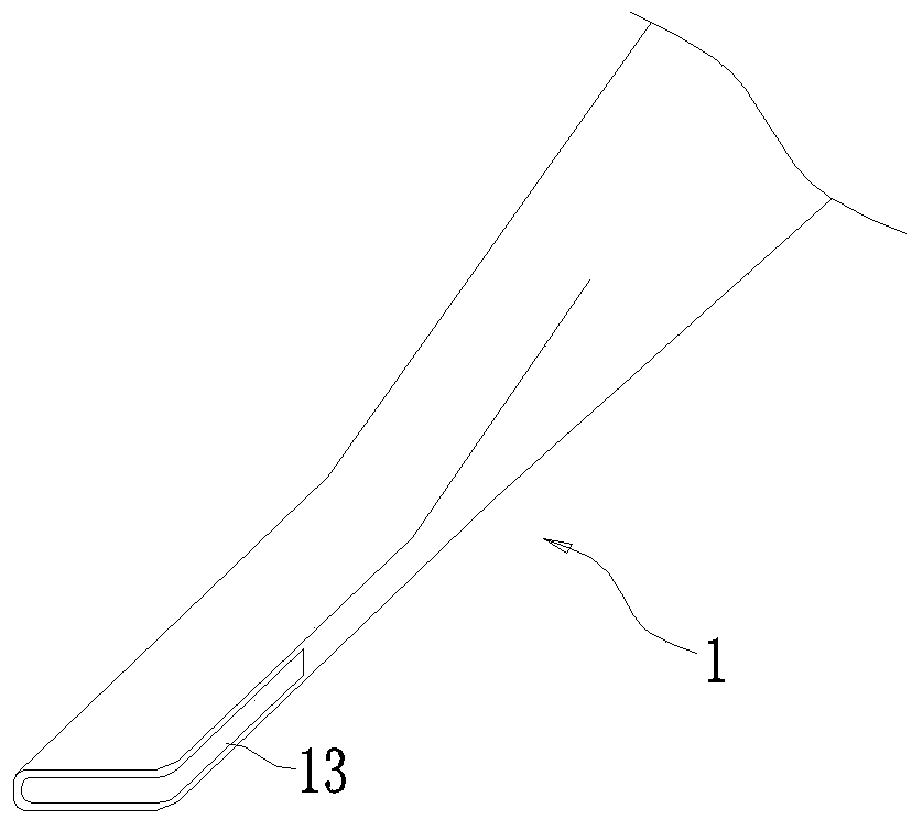

[0062] (2) Insert the flat cannula with a blanking opening at the bottom into the blank, so that the flat cannula moves in a direction parallel to the blank, and at the same time, the colored powder in the flat cannula falls to fill the gap formed by the movement of the flat cannula in the blank. , forming the underlying thin line texture;

[0063] The bottom and sides of the flat cannula form an L-shaped blanking opening. The depth at which the flat cannula is inserted into the blank is 1 to 3 mm from the bottom surface of the blank. The thickness of the flat cannula is 15-20 mm and the width is 1-2 mm. Multiple flat cannulas move in the blank with different moving paths, and the multiple paths intersect, parallel or overlap each other....

Embodiment 2

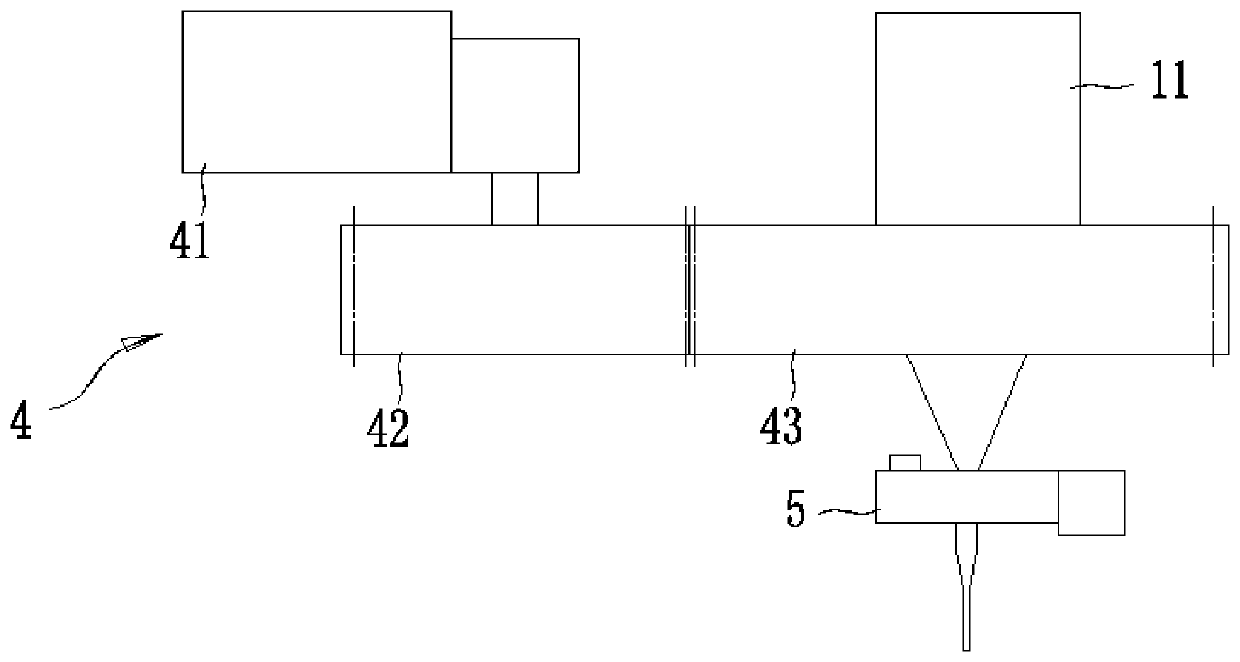

[0073] A method for distributing simulated ceramic tiles with internal thin-line texture, comprising steps (1) to (5), as follows.

[0074] (1) The basic powder is distributed on the conveyor belt to obtain the blank.

[0075] (2) Insert the flat cannula with a blanking opening at the bottom into the blank, so that the flat cannula moves in a direction parallel to the blank, and at the same time, the colored powder in the flat cannula falls to fill the gap formed by the movement of the flat cannula in the blank. , forming the underlying thin line texture;

[0076] The bottom and sides of the flat cannula form an L-shaped blanking opening. The depth at which the flat cannula is inserted into the blank is 1 to 3 mm from the bottom surface of the blank. The thickness of the flat cannula is 15-20 mm and the width is 1-2 mm. Multiple flat cannulas move in the blank with different moving paths, and the multiple paths intersect, parallel or overlap each other.

[0077] (3) Arrang...

Embodiment 3

[0089] A method for distributing simulated ceramic tiles with internal thin-line texture, comprising steps (1) to (5), as follows.

[0090] (1) The basic powder is distributed on the conveyor belt to obtain the blank.

[0091] (2) Insert the flat cannula with a blanking opening at the bottom into the blank, so that the flat cannula moves in a direction parallel to the blank, and at the same time, the colored powder in the flat cannula falls to fill the gap formed by the movement of the flat cannula in the blank. , forming the underlying thin line texture;

[0092] The bottom and sides of the flat cannula form an L-shaped blanking opening. The depth at which the flat cannula is inserted into the blank is 1 to 3 mm from the bottom surface of the blank. The thickness of the flat cannula is 15-20 mm and the width is 1-2 mm. Multiple flat cannulas move in the blank with different moving paths, and the multiple paths intersect, parallel or overlap each other.

[0093] (3) Pressing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com