Method and apparatus for quality control in the manufacture of composite materials

A technology for composite materials and quality control, which is used in the field of quality control and equipment in the manufacture of composite materials, and can solve problems such as lack of product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

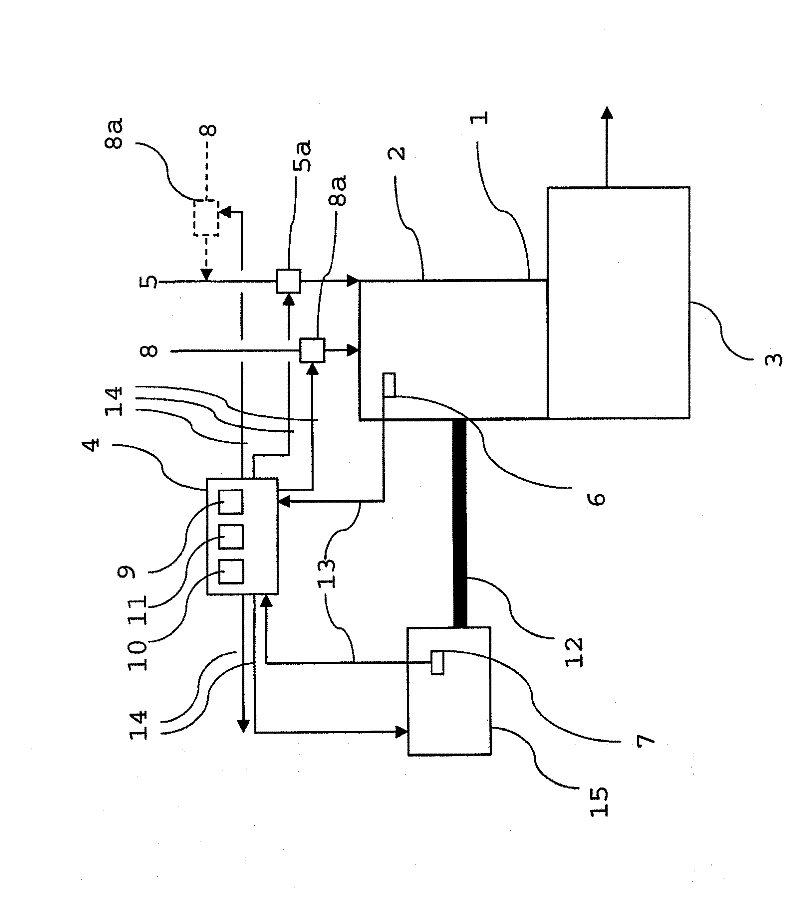

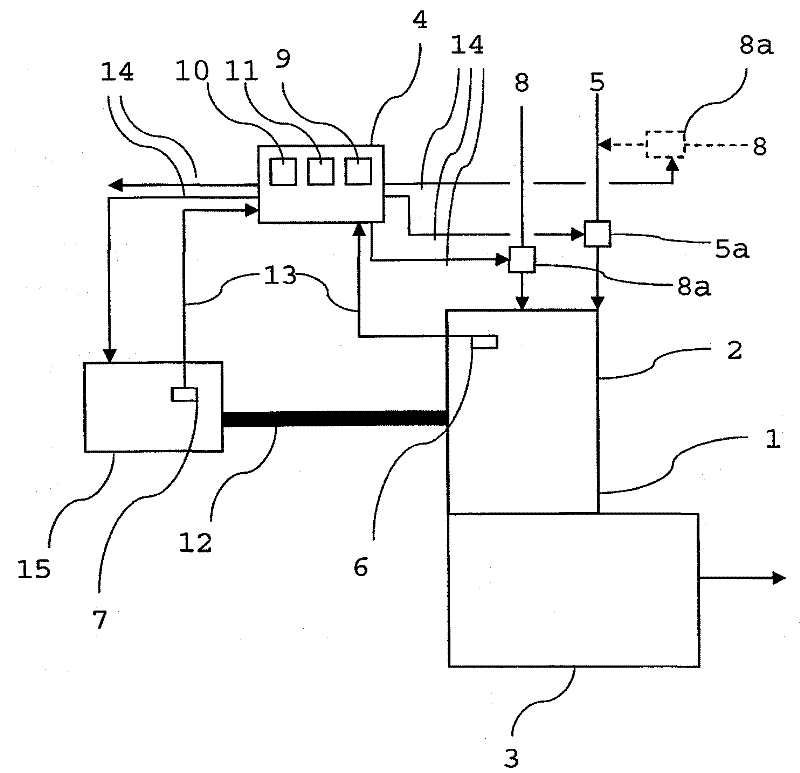

[0064] In this test, the examiner passes the figure 1 The formation of agglomerates in the mixing equipment and the quality of the agglomerates provided.

[0065]The quality of the agglomerates is controlled by observing process variables and adjusting the control parameters of the mixing process, ie the supply of raw materials, additional material and additional plastic, and the rotational speed of the mixer, based on the observations obtained from the process variables. Process variables to be observed include temperature and current consumption. If necessary, the supply of raw material, additional material and / or additional plastic can be interrupted.

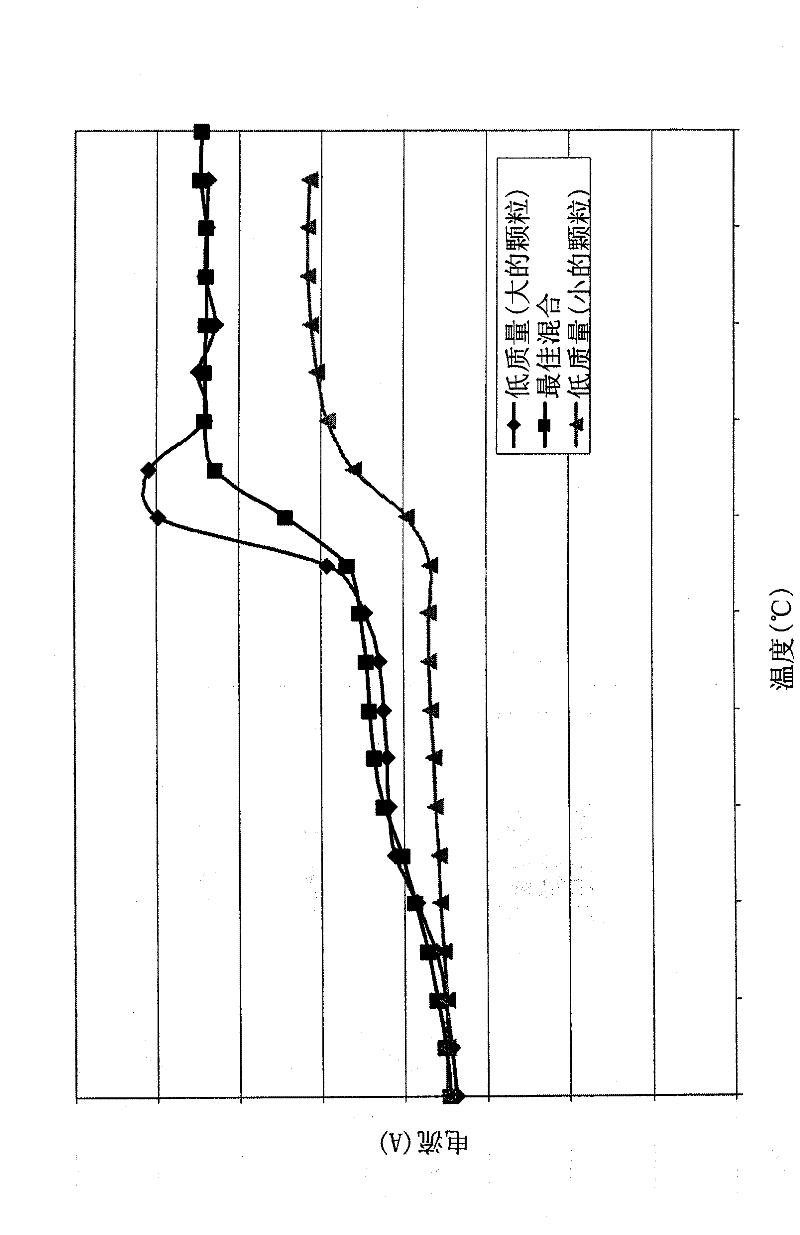

[0066] figure 2 Provides the current draw measured during the test as a function of temperature. The resulting process variable curves were compared to known process variable curves for the formation of agglomerates of good quality. Based on this comparison, the control parameters are adjusted to the correct direction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com