Wire drawing machine

A wire drawing machine and wire drawing technology, applied in the field of wire drawing machines, can solve the problems of not being able to produce multiple types of wire rods, large operating manpower expenditure, and low production efficiency, and achieve the effects of compact structure, small footprint, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

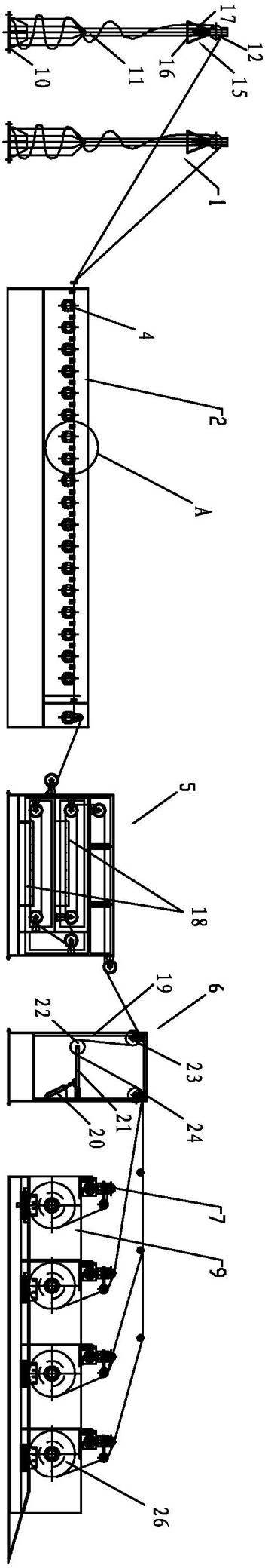

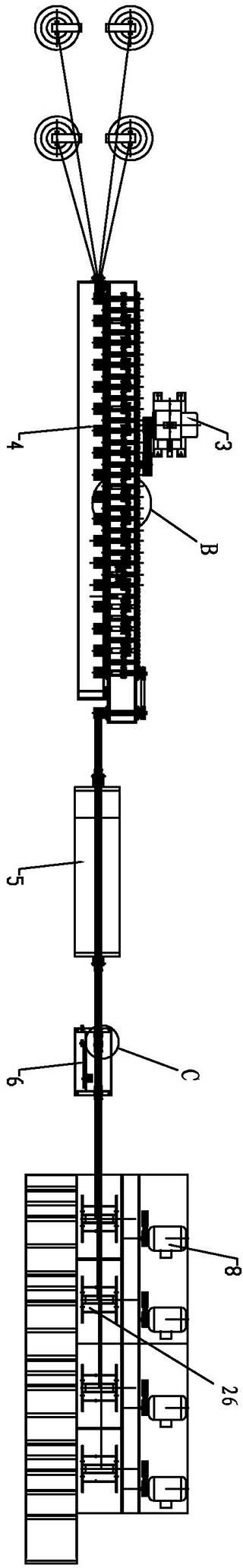

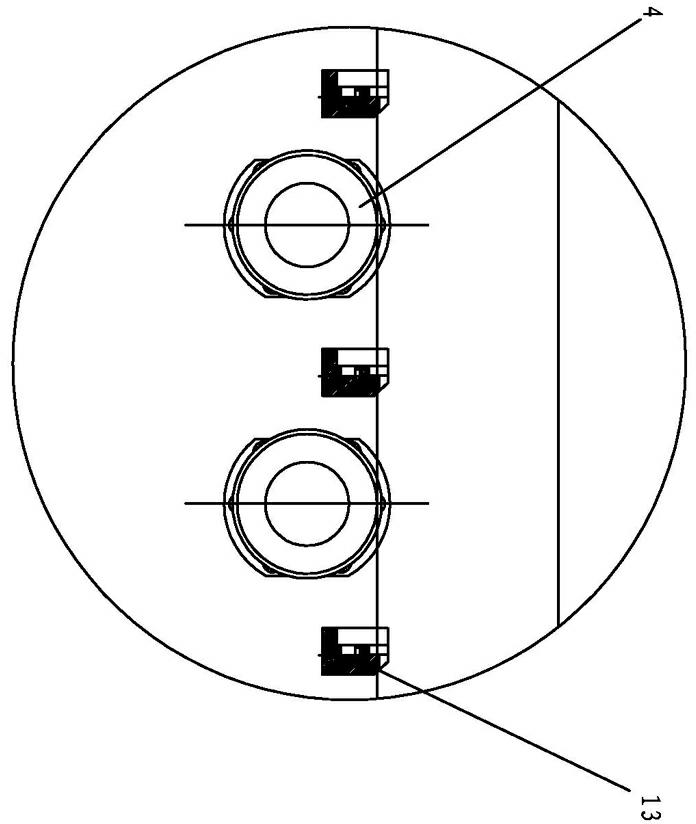

[0021] refer to Figure 1 to Figure 5 , a wire drawing machine, comprising four pay-off devices 1, a wire draw device 2 behind the pay-off device 1 and a wire take-up device 9 behind the wire draw device 2, the pay-off device 1 comprising a base 10 fixed on the ground, the base 10 A pole 11 is installed on the pole 11, and a wire wheel 12 is installed on the top of the pole 11; the wire drawing device 2 includes several wire drawing wheels 4 for winding metal wires, and four extrusion wheels 4 are arranged between adjacent two wire drawing wheels 4. Die 13, several drawing wheels 4 are driven by gear 14, and are connected with main motor 3 transmissions. Wherein, the drawing wheel 4 is provided with four rolling grooves 27 . Put the wire harness on the base 10 of the pay-off device 1, then pull the wire upwards, let the metal wire cross the wire wheel 12 on the top of the pole 11, then let the metal wire wrap around the wire drawing wheel 4, and then pass through the extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com