Heating furnace upright post cofferdam internal mold and making method thereof

A production method and heating furnace technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems affecting the construction period, increasing cleaning work, affecting the quality of pouring finished products, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

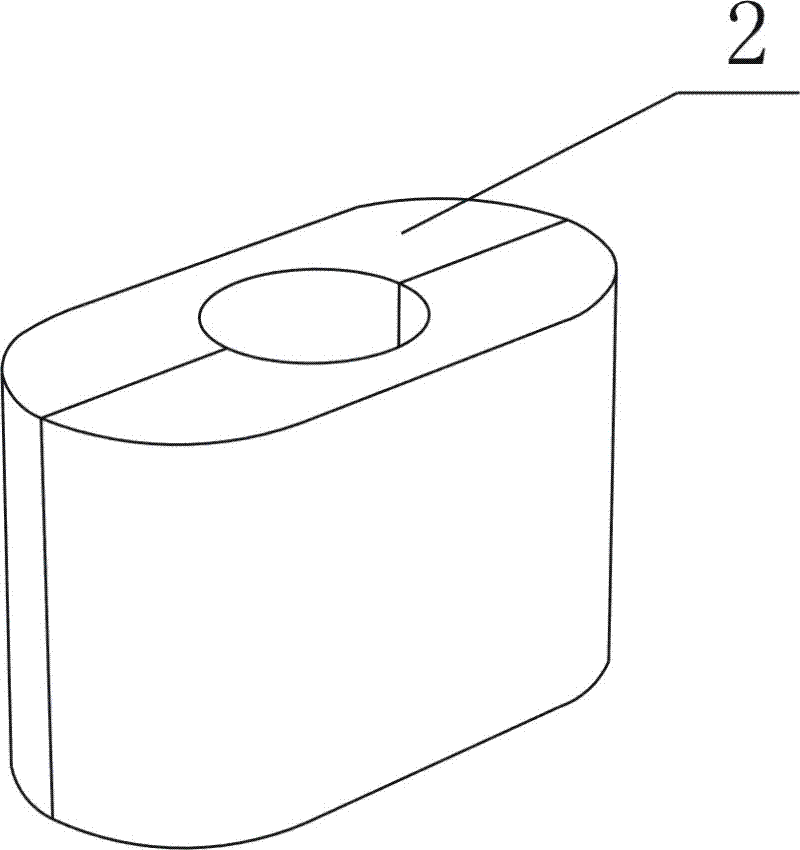

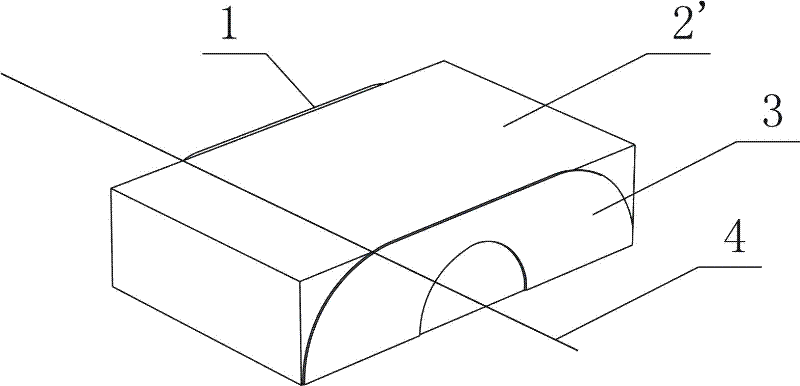

[0024] Such as figure 1 As shown, the inner mold of the heating furnace column embankment of the present invention has a circular through hole axially, and the diameter of the circular hole is equal to the outer diameter of the movable column 8, which can just pass through the movable column 8. Die internal mold member 2 of one-half mold. The splicing line of a pair of dike inner mold components 2 on the section of the dike inner mold is the center line of the section of the dike inner mold along the length direction, and its material is expanded polystyrene.

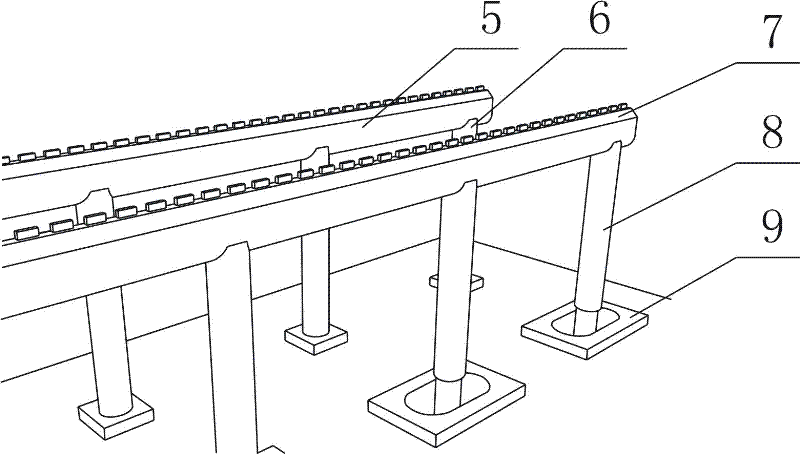

[0025] Such as image 3 As shown, the operation of supporting the dike inner mold and pouring is roughly as follows: wrap the two processed dike inner mold members 2 around the movable column 8, use wide adhesive tape to tighten a pair of dike inner mold members 2, And seal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com