Patents

Literature

38results about How to "Craft time saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

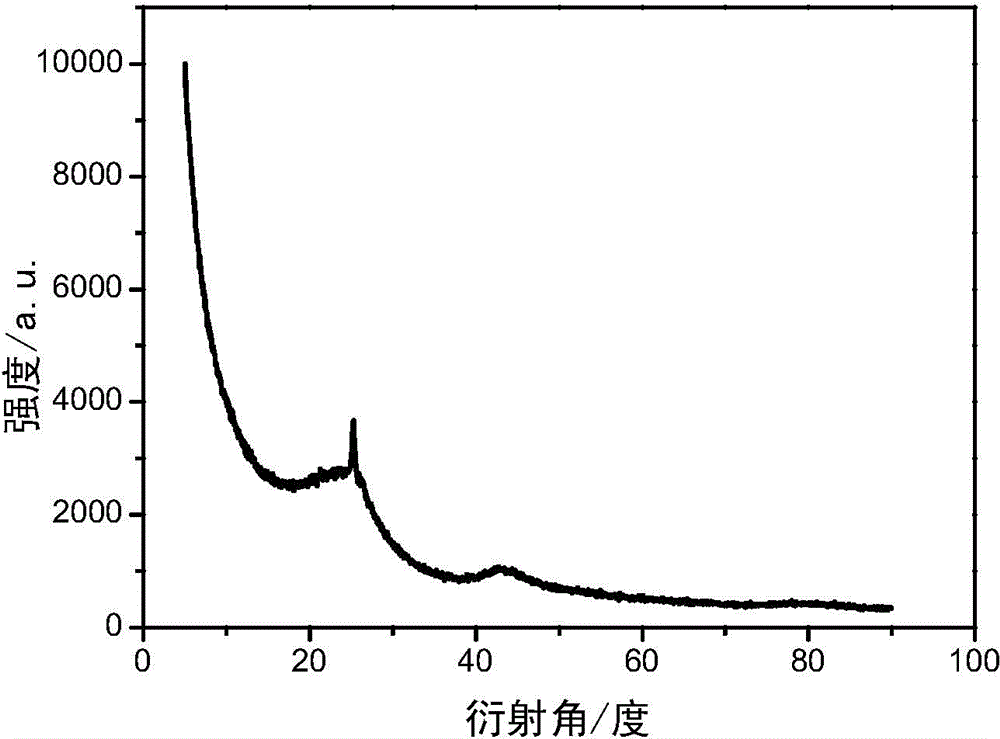

Method for preparing carbon nitride/ titanium dioxide heterojunction photocatalyst in one-step electrostatic spinning way

ActiveCN107456987AThe method is simple and time-savingImprove utilization efficiencyWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic degradationElectrospinning

The invention belongs to the technical field of photocatalysts for degrading organic sewage, and specifically relates to a method for preparing a carbon nitride / titanium dioxide heterojunction photocatalyst in one-step electrostatic spinning way. The heterojunction photocatalyst is prepared in the one-step electrostatic spinning way, wherein the one-step electrostatic spinning way specifically comprises the following steps: adding melamine or guanidine hydrochloride or urea to a mixed solution containing glacial acetic acid, tetrabutyl titanate, polyvinylpyrrolidone and an organic solvent; then performing the electrostatic spinning technology and the high-temperature sintering treatment to obtain the carbon nitride / titanium dioxide heterojunction photocatalyst. The prepared photocatalyst is outstanding in heterojunction and outstanding in performance of photocatalyzing degrading the organic sewage; the preparation technology of the carbon nitride / titanium dioxide heterojunction photocatalyst is simplified; the technology is simple; the time is saved. Therefore, the method has a good application prospect in organic sewage treatment.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Enzymolysis preparation of Cordyce militaris polypeptide and product

InactiveCN101469338APromote absorptionNo pollution in the processFermentationPlant ingredientsWater bathsUltrafiltration

The invention provides a method for preparing polypeptide of Cordyceps militaris by enzymolysis and product development. Cultivated Cordyceps militaris is dried at a temperature of between 37 and 72 DEG C and is crushed into powder, a biocatalyst (enzyme) of which weight is 0.007 to 0.05 percent of the weight of the Cordyceps militaris is added, and a zymoexciter is added at the same time. The hydrolysis is performed for 3 to 6h under water bath condition that the temperature is between 25 and 55 DEG C and the pH value is between 1.0 and 10.0, then the centrifugation and ultrafiltration are performed to obtain a clear yellowy Cordyceps militaris hydrolysate, and the hydrolysis rate is between 70 and 80 percent. The Cordyceps militaris hydrolysate contains a large amount of small molecular polypeptide, growth factors, esters (phospholipid, steroid compounds, fatty acid, and so on), more than 20 amino acids, trace elements and various effective medicinal components such as cordycepin, cordycepic acid, and so on. An obtained product can be applied to a plurality of aspects such as pharmacy, health care products and food, cosmetics, and so on, has convenient application, time saving and no pollution, and can develop a plurality of new products.

Owner:吴益民

Biological enzyme desizing enzyme wash-bath process of pure cotton and cotton-containing type blended denim clothing

ActiveCN104452315AReduced desizingNo generationBiochemical fibre treatmentDry-cleaning apparatus for textilesState of artDenim

The invention relates to a biological enzyme desizing enzyme wash-bath process of pure cotton and cotton-containing type blended denim clothing. The process comprises the following steps: (1) performing desizing enzyme wash-bath: adding the denim clothing into an industrial washing machine, adding water, heating the water to 40-50 DEG C, adding desizing enzyme wash-bath enzyme into the industrial washing machine, controlling the pH value of the solution to be 6.0-8.0, opening the industrial washing machine, preserving the heat and rotating for 30-90 minutes, discharging the solution and washing for two times with clear water; (2) neutralizing with a reducing agent: adding the clothing on which monkey is sprayed into the industrial washing machine, adding water, heating the water to 25-40 DEG C, adding the reducing agent into the industrial washing machine, controlling the pH value of the solution to be 5.0-7.0, controlling the total hardness of water of the solution to be 70-150 ppm, opening the industrial washing machine, preserving the heating and rotating for 5-20 minutes, discharging the solution and cleaning for 1-2 times with clear water. Compared with the prior art, the process has the advantages that the process is time-saving, simple, easy to control and rational, no toxic or harmful substance is produced, the production efficiency is obviously improved, the product quality is more stable, and the production comprehensive cost is greatly reduced.

Owner:FIBER CHEM BIOLOGICAL CHEM

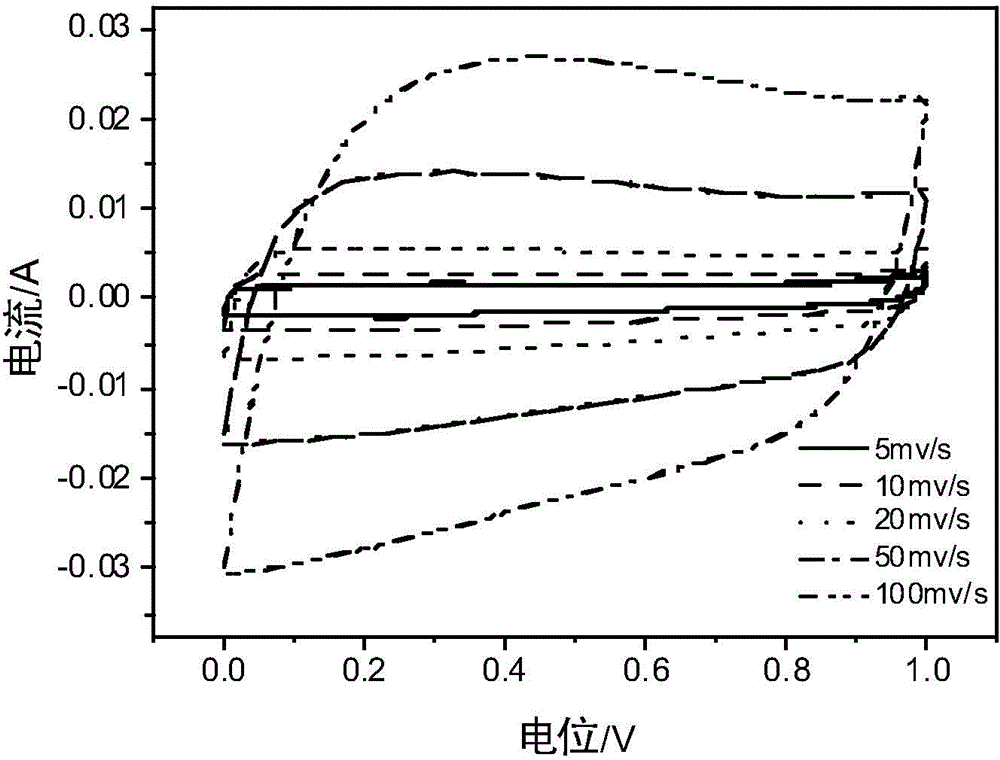

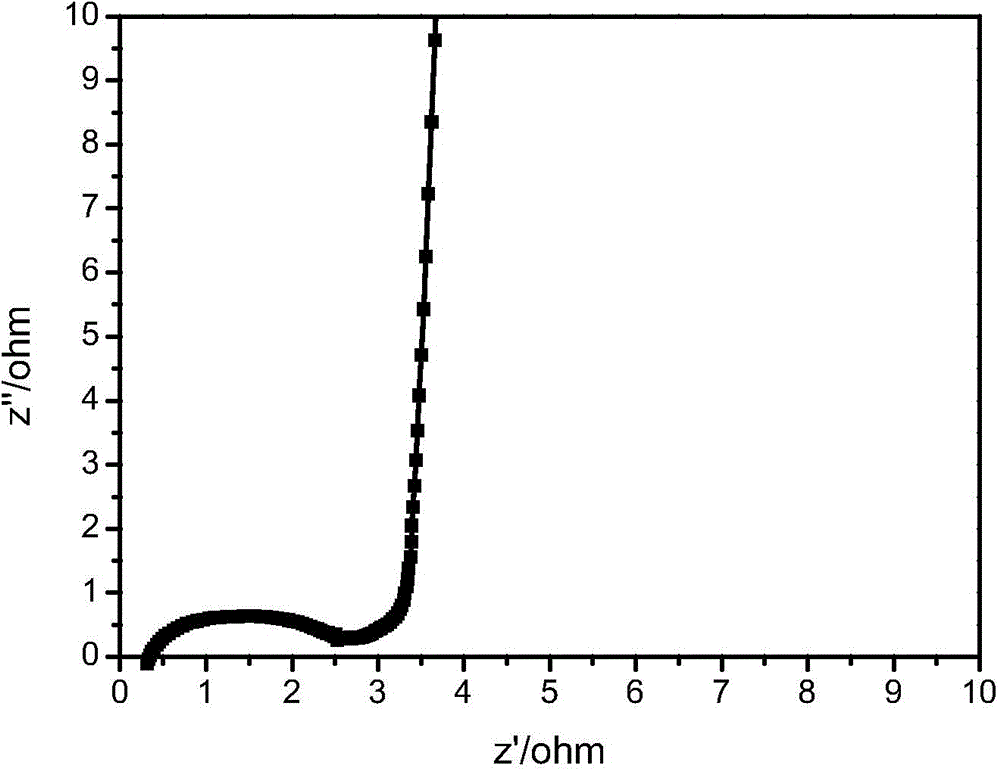

High-magnification active carbon and active graphene composite electrode material and preparation method thereof

ActiveCN105321726AHigh specific capacityImproved magnification performanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMoisture

The invention relates to a high-magnification active carbon and active graphene composite electrode material and a preparation method thereof. The material is characterized in that active carbon is uniformly dispersed into an activator-contained oxidized graphene solution and heated to remove moisture therein, an obtained mixture is reduced and activated at certain temperature in the protective atmosphere, and a product is washed, filtered and dried to obtain the active carbon and active graphene composite electrode material. The active carbon and active graphene composite electrode material provided by the invention is high in the specific capacity and magnification, and the specific capacitive of the material is kept in 250F / g in the current density range of 2-10A / g; and the preparation method of the material is simple in technical process, saves time, is low in cost and is easy to realize large-scale industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Water-based rust-converting anti-corrosive primer

ActiveCN104403435AHigh viscosityLabor-saving processAnti-corrosive paintsWater basedChemical reaction

A water-based rust-converting anti-corrosive primer belongs to the technical field of water-based paint products and is characterized by comprising the following components in parts by weight: 40 to 50 parts of a water-based rust-converting agent, 30 to 40 parts of an anion-modified emulsion, 1 to 3 parts of a stabilizer, 1 to 3 parts of a defoamer, 1 to 10 pats of a thickener and 10 to 20 parts of deionized water. According to the primer provided by the invention, chemical reaction occurs between the water-based rust-converting agent and rust on the surface of metal, so that the rust of ferric oxide (Fe2O3) is reduced to ferric (Fe) which can be almost dissolved with steel as a whole, and then calcium, manganese, chromium, nickel or other metal in the steel is converted into an alloy film. When in use, the primer can be sprayed directly to achieve the best effect, and primer, intermediate coat and finishing coat can be omitted, so that the cost for rust protection is greatly lowered, and the labor intensity and the working time are decreased at the same time.

Owner:ZIBO HUIHE PAINT

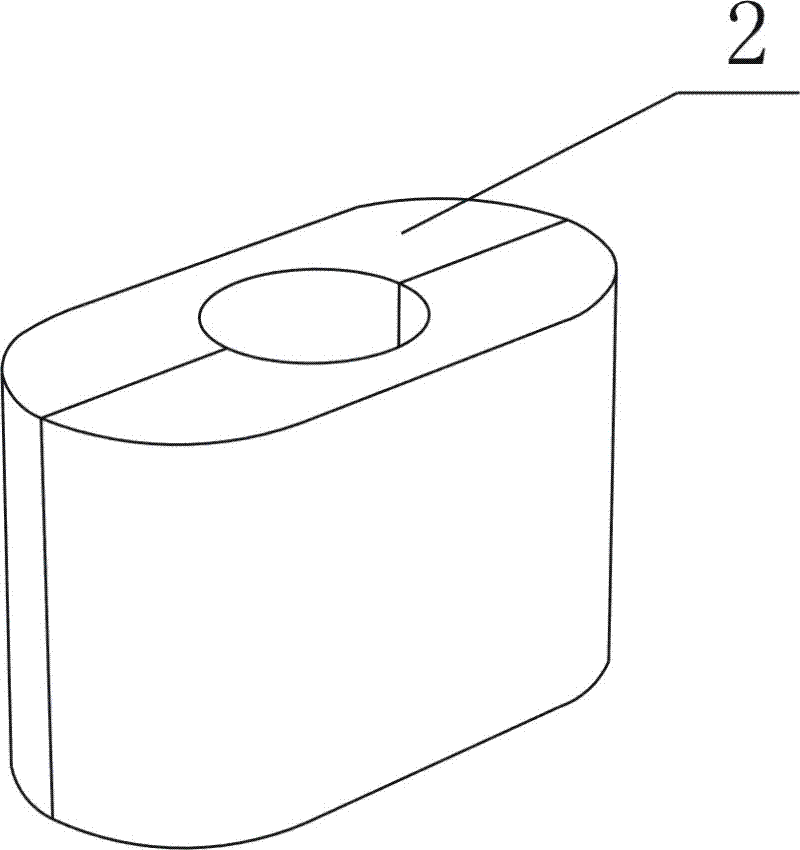

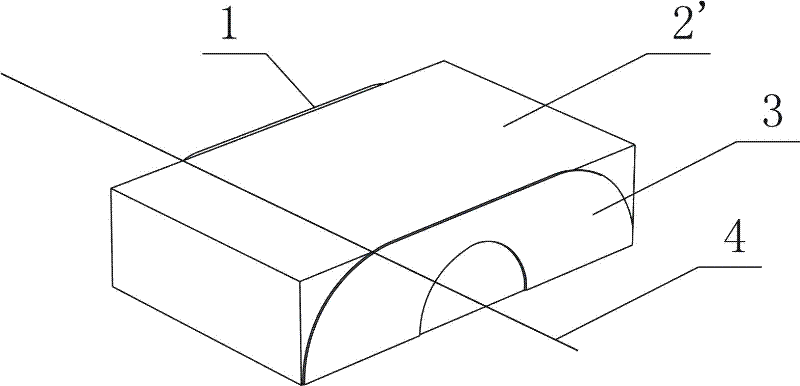

Heating furnace upright post cofferdam internal mold and making method thereof

ActiveCN102303359AFull time maintenancePrevent fallingCeramic shaping apparatusCofferdamHeating furnace

The invention discloses a heating furnace upright post cofferdam internal mold. The cofferdam internal mold is axially provided with a through hole through which a movable upright post passes, and the cofferdam internal mold comprises a pair of cofferdam internal mold members in a size which is half of the cofferdam internal mold. The cofferdam internal mold is characterized in that: the cofferdam internal mold members are made of expanded polystyrene. A making method of the heating furnace upright post cofferdam internal mold comprises the following steps of: 1) making a pair of sample plates in a size which is half of the section of the cofferdam internal mold; 2) making an expanded polystyrene board into a preformed block, the height of which is equal to that of the cofferdam internal mold and the section of which is greater than or equal to half of the section of the cofferdam internal mold; and 3) tidily putting the pair of sample plates made in the step 1) on two sections of the preformed block in parallel, cutting the preformed block along the outlines of the pair of sample plates to obtain the cofferdam internal mold members in a size which is half of the cofferdam internal mold, and thus forming the heating furnace upright post cofferdam internal mold by using the pair of cofferdam internal mold members. The cofferdam internal mold is convenient and fast for supporting, simple in making and low in cost.

Owner:CHINA FIRST METALLURGICAL GROUP

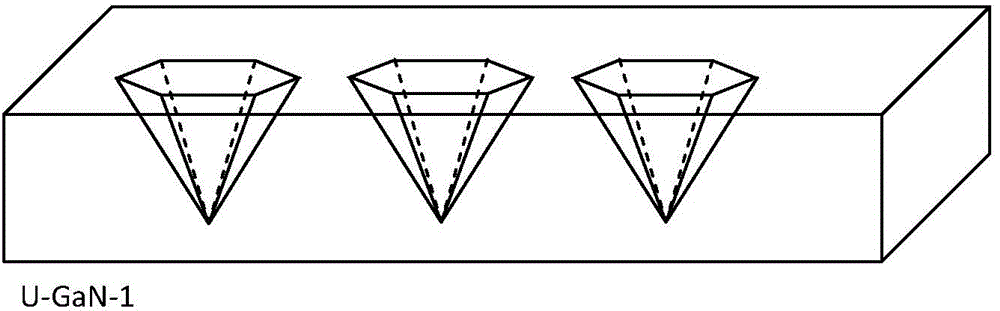

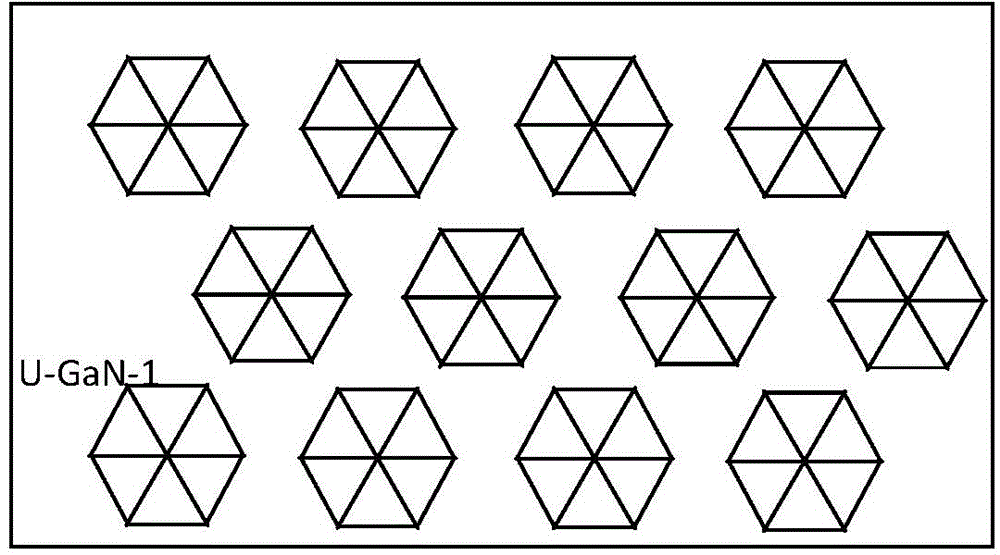

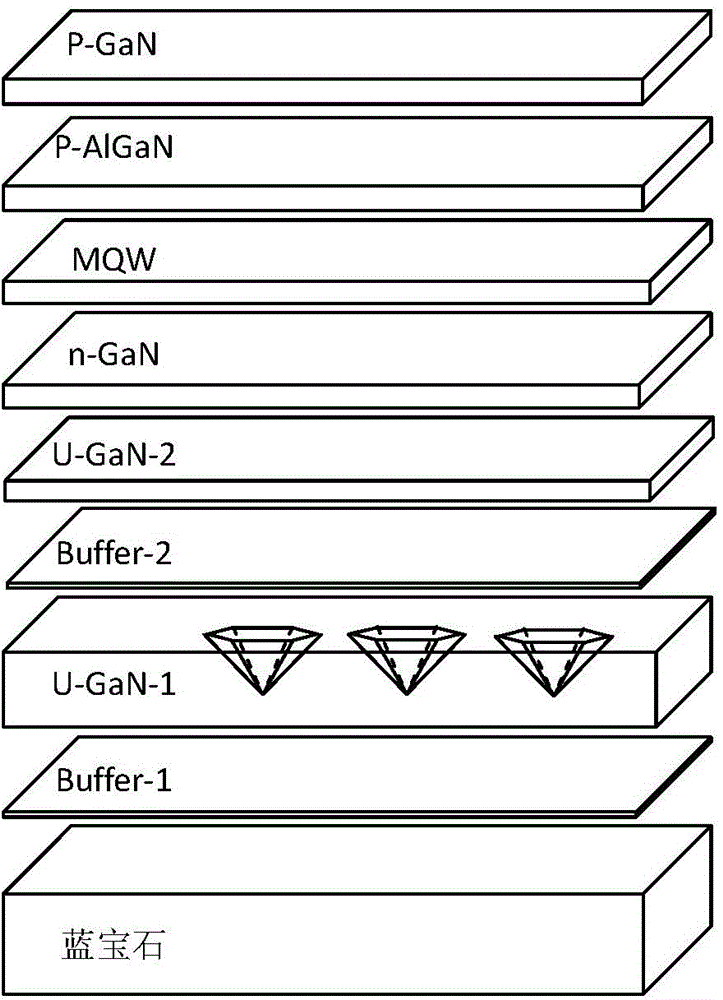

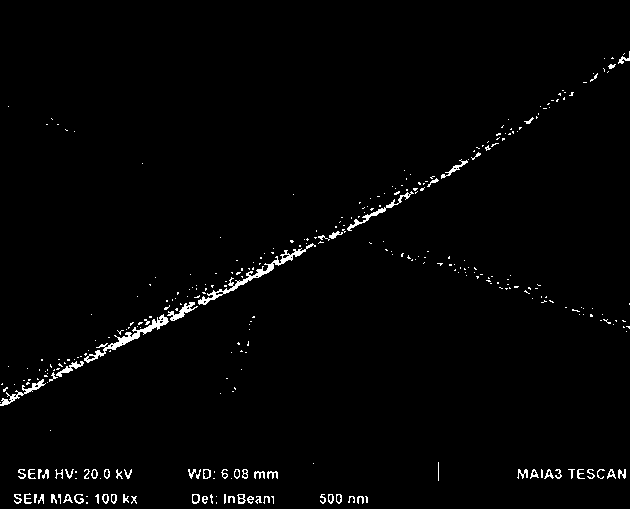

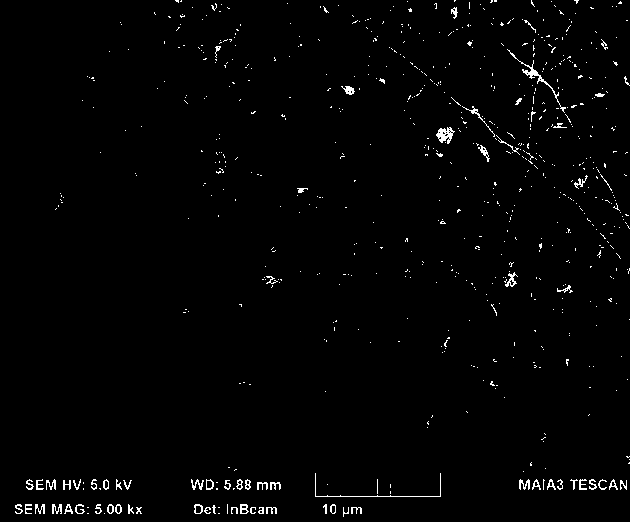

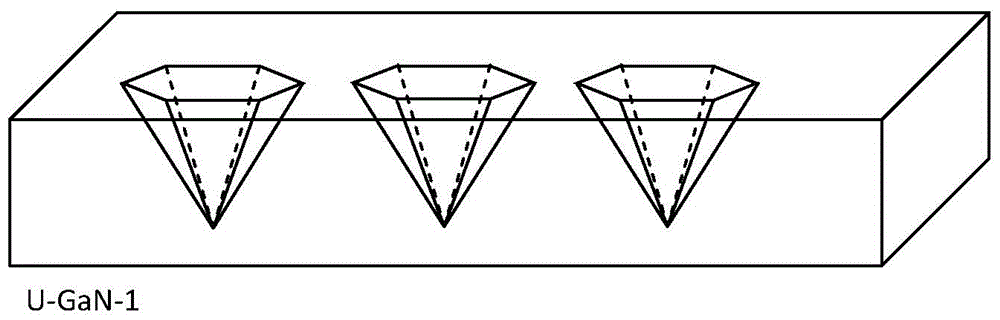

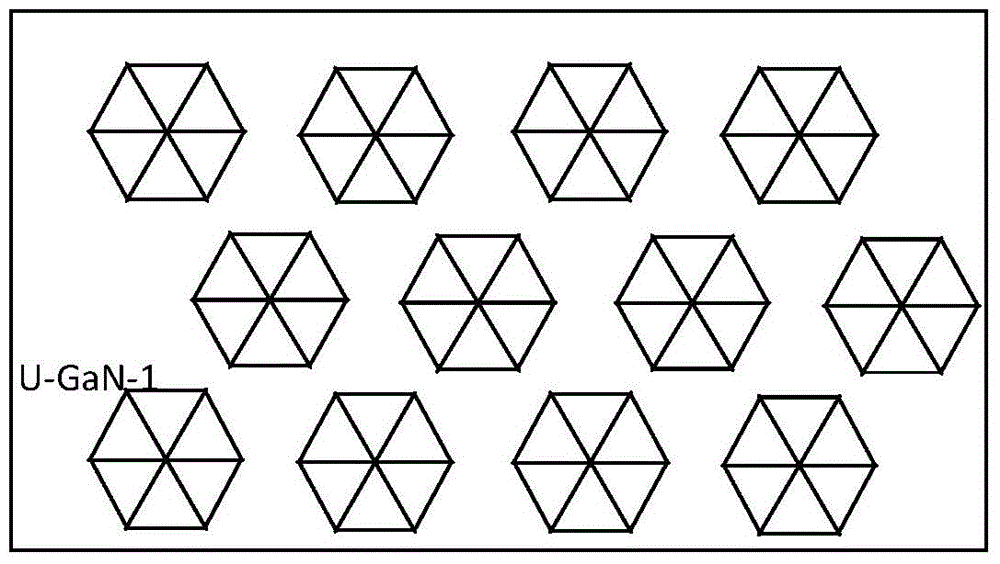

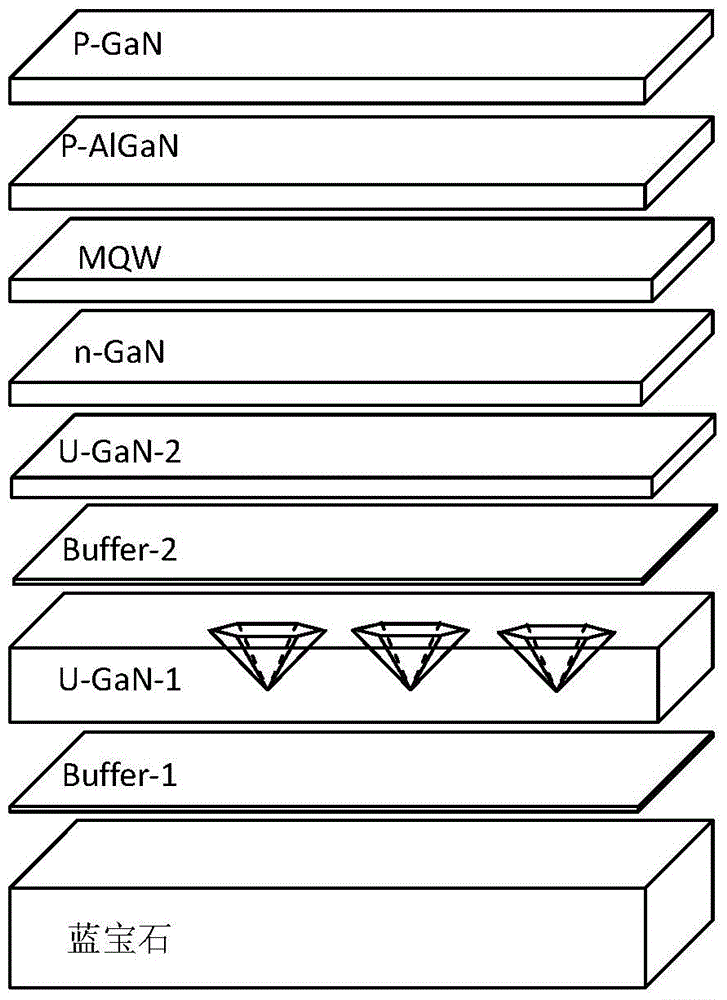

Transverse epitaxial growth method for double buffer layers for improving brightness of LED (Light Emitting Diode)

InactiveCN104900774AQuality improvementAvoid secondary pollution and other problemsSemiconductor devicesSulfateQuantum well

The invention discloses a transverse epitaxial growth method for double buffer layers for improving the brightness of an LED (Light Emitting Diode). The method comprises the following steps: 1) growing a first AlxGa1-xN buffer layer at a low temperature by using conical PSS (Polysaccharide Sulfate) as a growth substrate, wherein 0<=x<=1; 2) growing a first U-GaN layer with hexagonal conical array micro pits at a high temperature; 3) performing high-temperature annealing in an NH3 environment, then cooling to a low temperature, and growing a second low-temperature AlxGa1-xN buffer layer; 4) growing a second U-GaN layer at a high temperature to completely cover the hexagonal conical array micro pits of the first U-GaN layer, and forming cavities at the micro pits; 5) sequentially growing a SiH4-doped n-GaN layer, a multi-quantum well active layer, a doped p-type AlGaN barrier layer and a doped p-type GaN layer; and 6) annealing in nitrogen. According to the method, a layer of hexagonal conical array micro pits is grown on the sapphire substrate, and the buffer-2 is grown on the GaN in the area, namely GaN is grown on the GaN substrate, so that crystal nuclei with fewer defects, lower internal stress and lower crystal orientation difference can be obtained.

Owner:西安明德理工学院

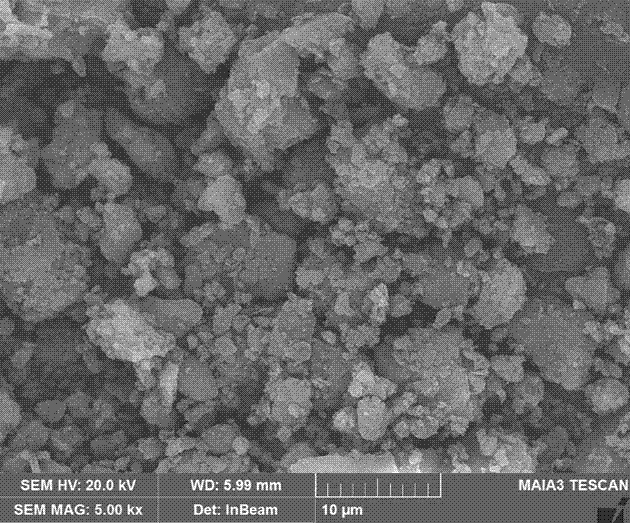

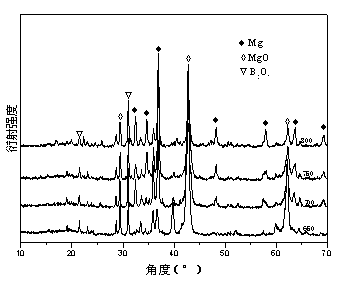

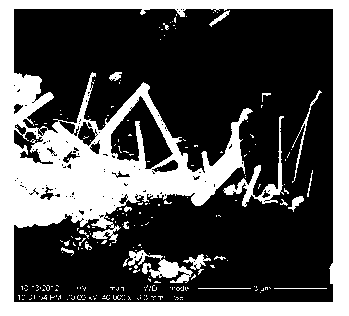

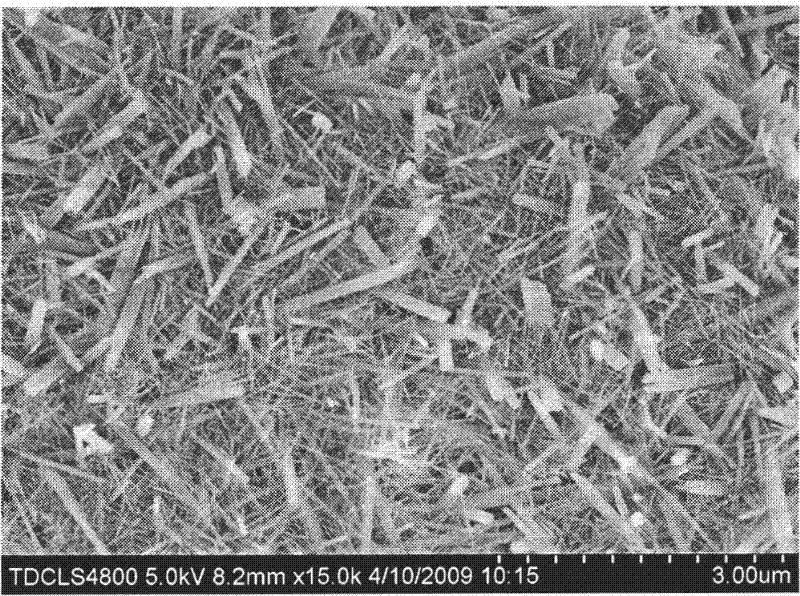

Method for preparing magnesium oxide whisker/ magnesium composite powder by in-situ growth on surface of magnesium powder

InactiveCN103008652ASimple processCraft time savingPolycrystalline material growthFrom solid stateMass ratioEthanol

The invention discloses a method for preparing a magnesium oxide whisker / magnesium composite powder by in-situ growth on the surface of magnesium powder, which belongs to the technology of a ceramic whisker / a metal composite powder material. The method comprises the steps of: first, dissolving boric acid adequately with an appropriate amount of absolute ethyl alcohol, then, dispersing magnesium powder with mass ratio of 1-3 with boric acid in the boric acid and ethanol solution, agitating at a constant temperature by a magnetic agitator, and taking out the sample and drying to obtain pre-mixed powder after completely evaporating absolute ethyl alcohol; paving the pre-mixed powder in a quartz ark and placing the quartz ark in a constant temperature area of a vacuum tubular heating furnace; and calcining at 650-800 DEG C under protection of argon to prepare the magnesium oxide whisker / magnesium composite powder. The method has the advantages that the process is simple and easy for realizing production in a large scale; magnesium oxide whiskers growing on a magnesium powder substrate are uniform in size and good in bonding performance with the magnesium powder substrate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

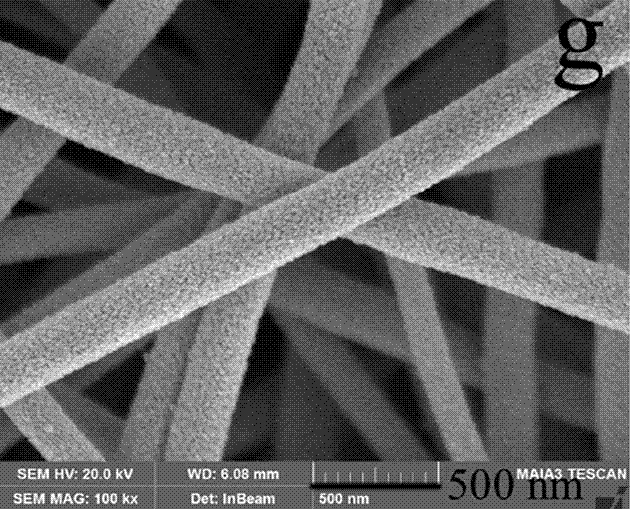

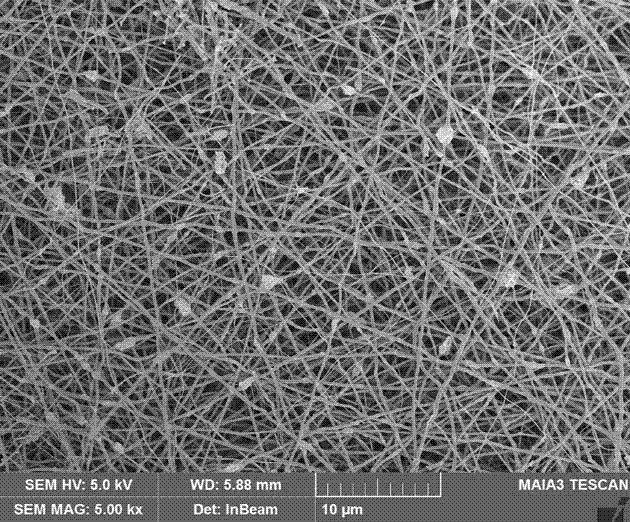

Preparation method of bionic nanofiber scaffold with electrical stimulation effects

InactiveCN105664240APromote regenerationEasy to manufactureFilament/thread formingPharmaceutical delivery mechanismFiberNeurotrophic factors

The invention discloses a preparation method of a composite bionic nanofiber scaffold with electrical stimulation effects. Beta-tricalcium phosphate is polarized for 0.5-3 hours in air with the effects of a 2-8KV / cm-1 direct-current electric field at 200-600 DEG C, and polarized beta-TCP is obtained; polylactic acid is dissolved in an organic solvent, the polarized beta-TCP powder is added, and PLA / beta-TCP pre-electrospinning liquid 1 is prepared; a medicament with biological activity is added in an aqueous solution of chitosan-acetic acid with uniformly stirring for dispersion, and CS / medicament with biological activity pre-electrospinning liquid 2 is prepared; PLA / CS / beta-TCP is prepared by coaxial electrospinning. The nanofiber scaffold with electrical stimulation effects has a double layer internal structure and a large surface area, in order to realize timely and proper controlled release of neurotrophic factors and various medicaments; the nanofiber scaffold has the advantages of good biological compatibility, stable performance, preservation convenience, and good application prospects in peripheral nerve repair and other biomedical fields.

Owner:WUHAN UNIV OF TECH

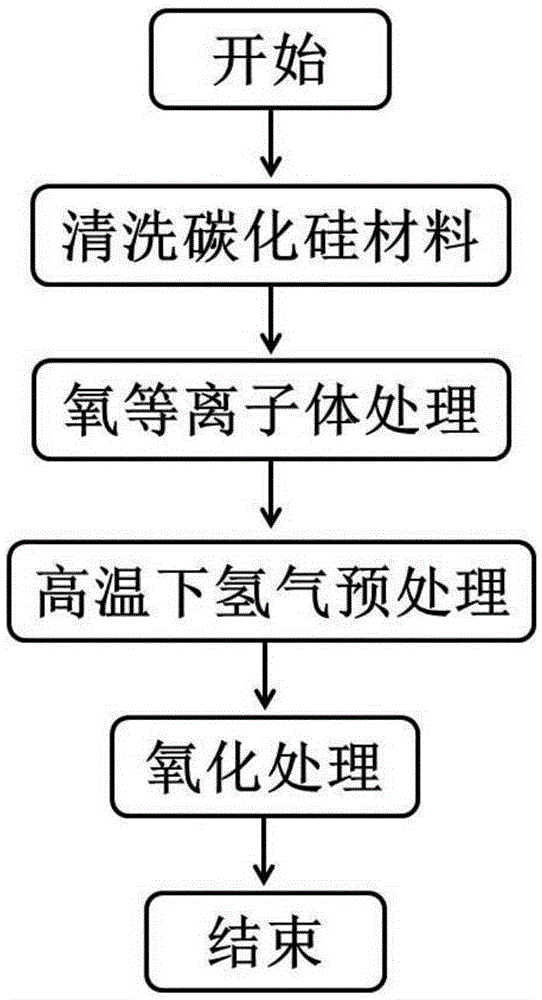

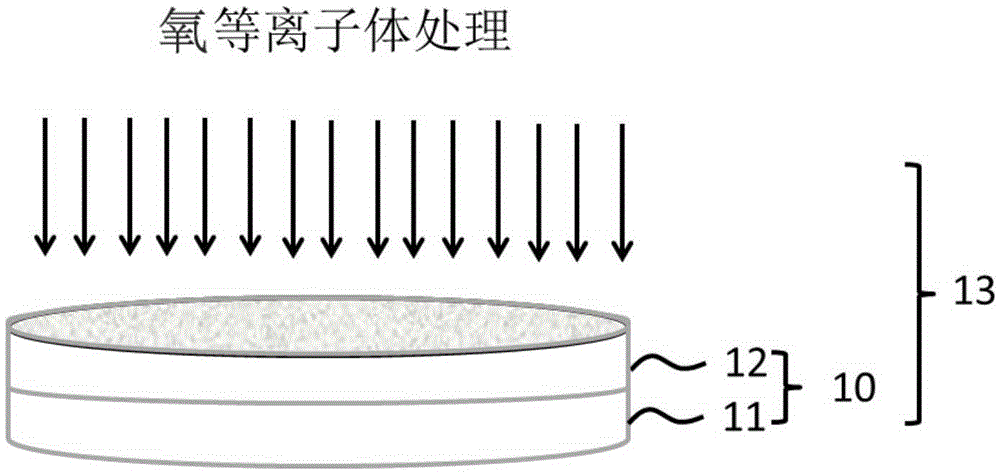

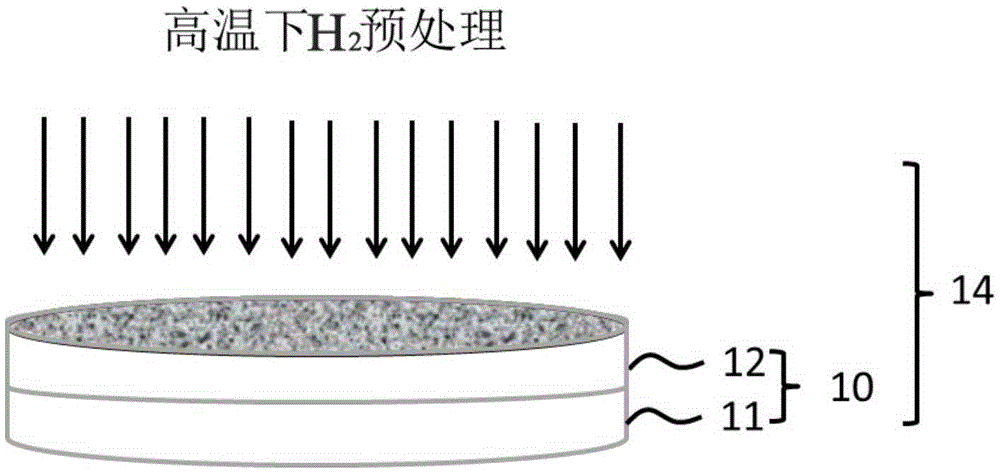

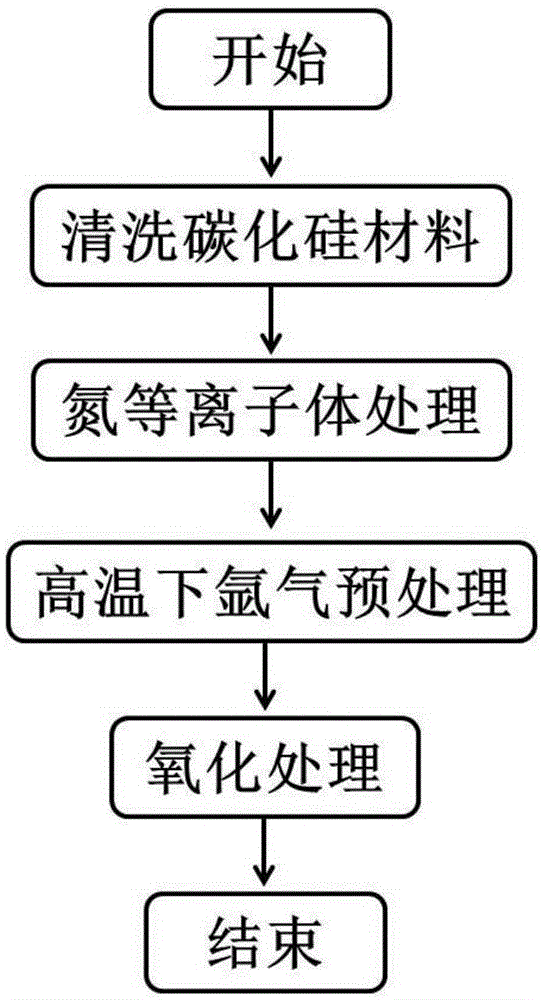

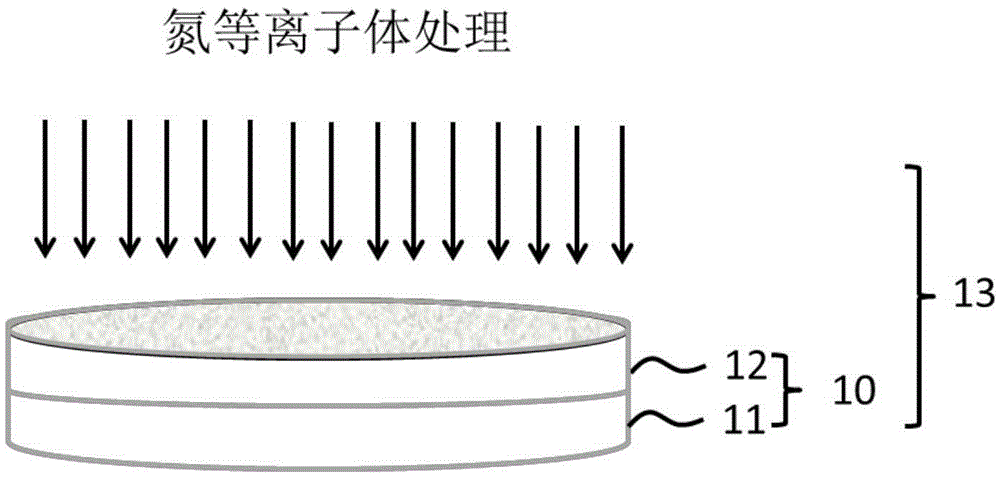

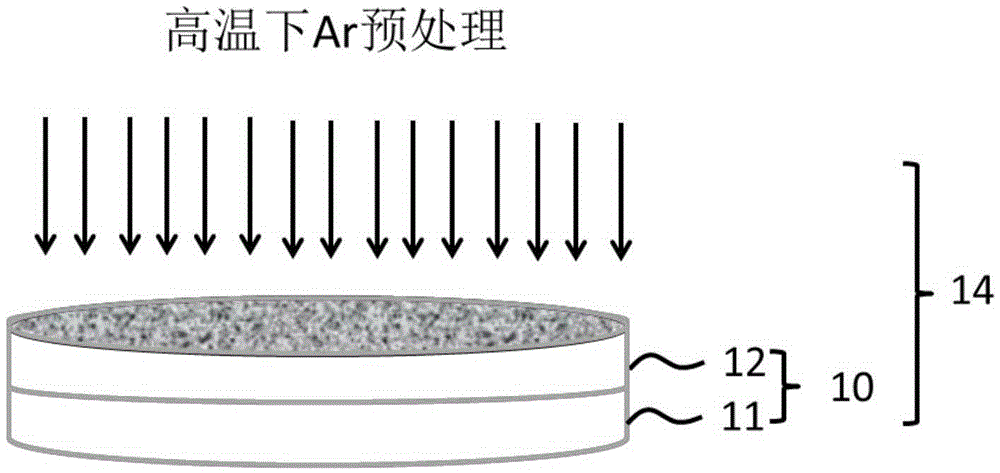

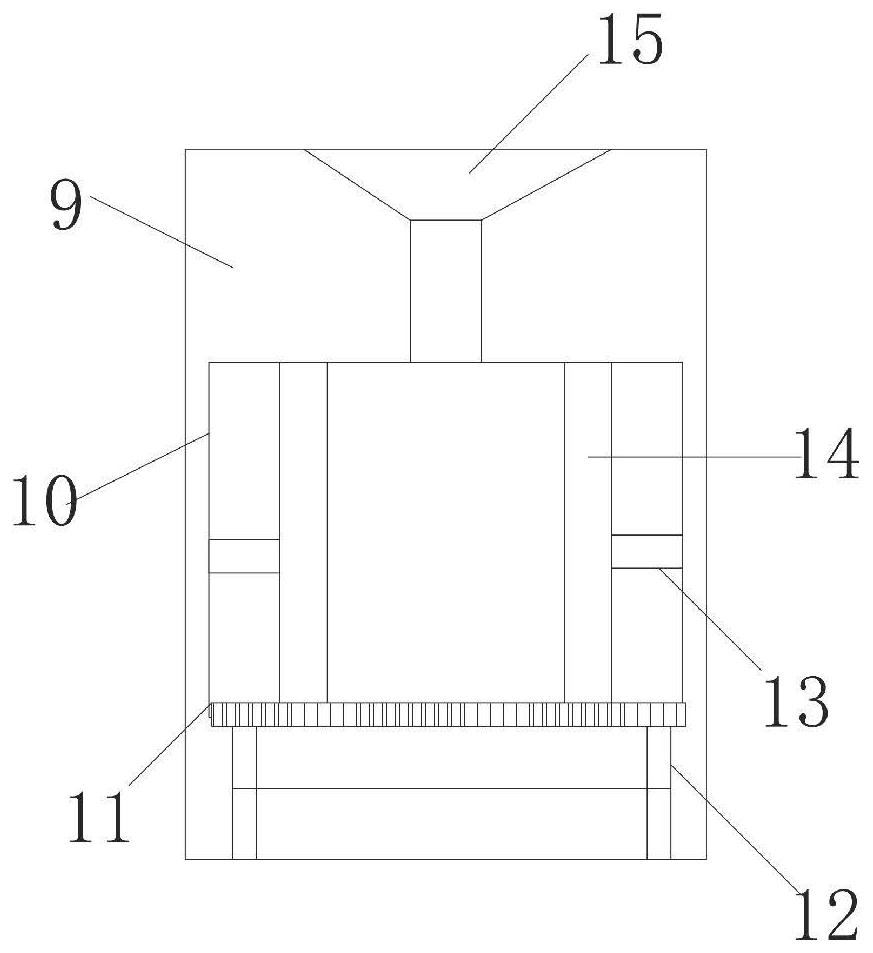

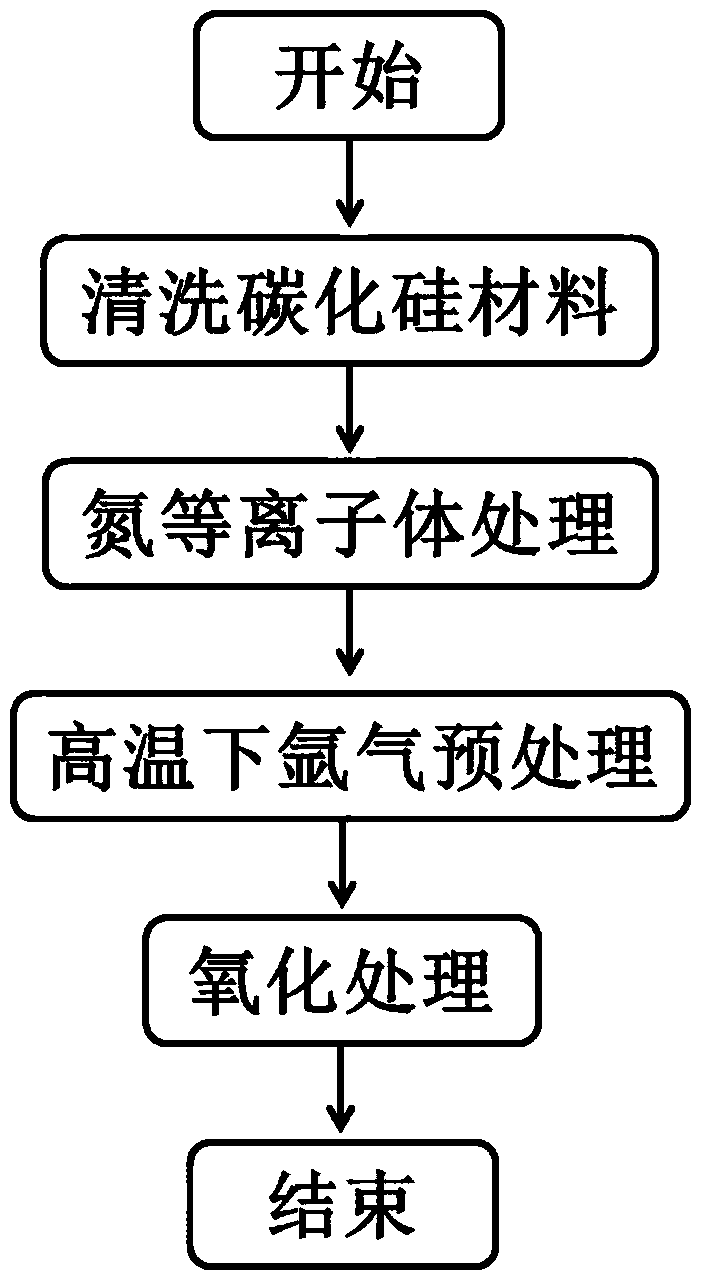

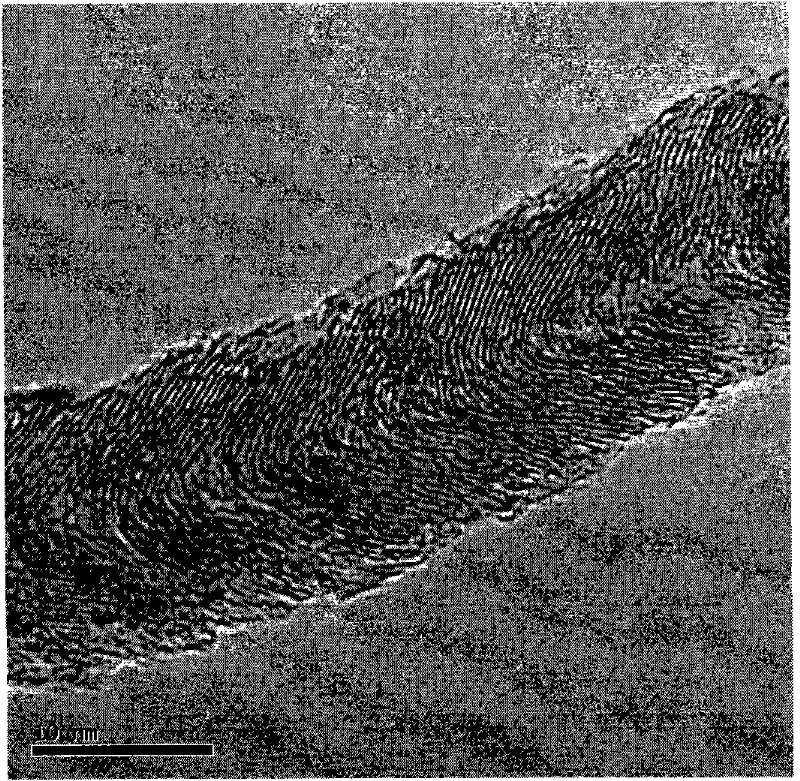

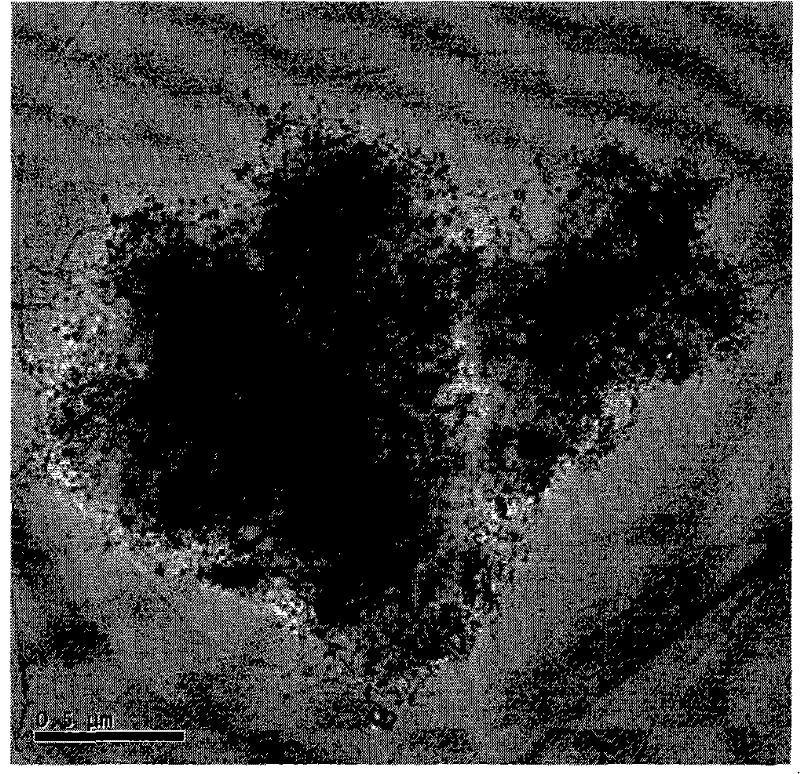

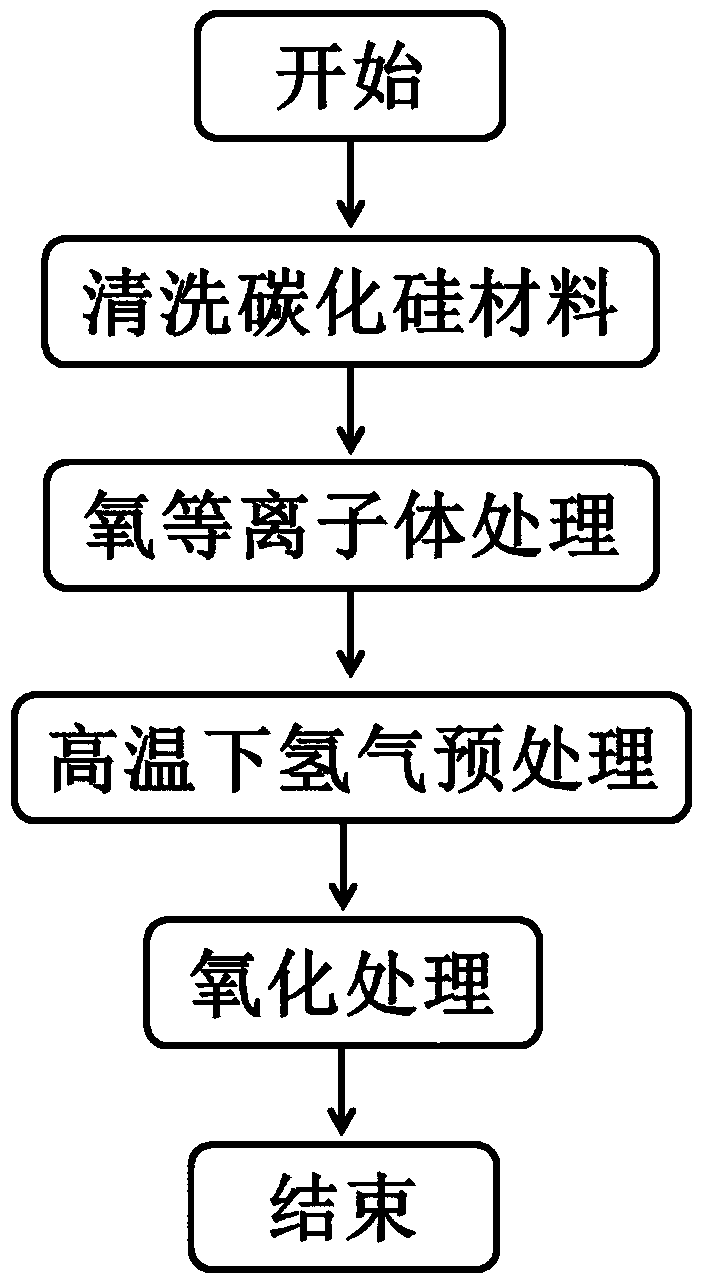

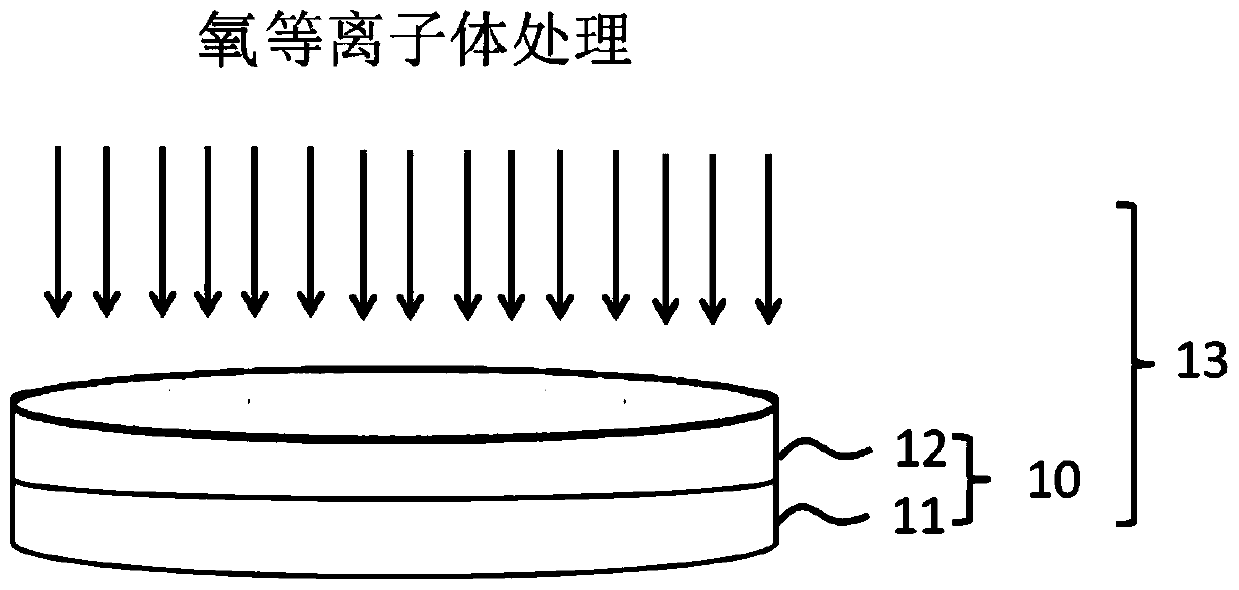

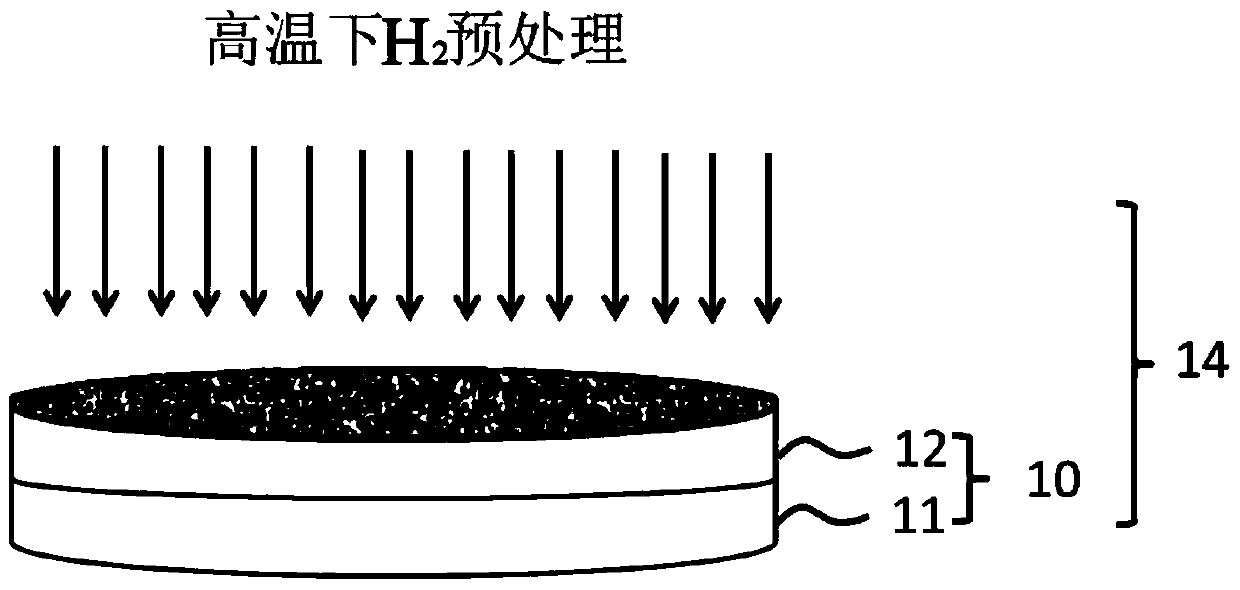

Preparation method of oxidization film in surface of silicon carbide

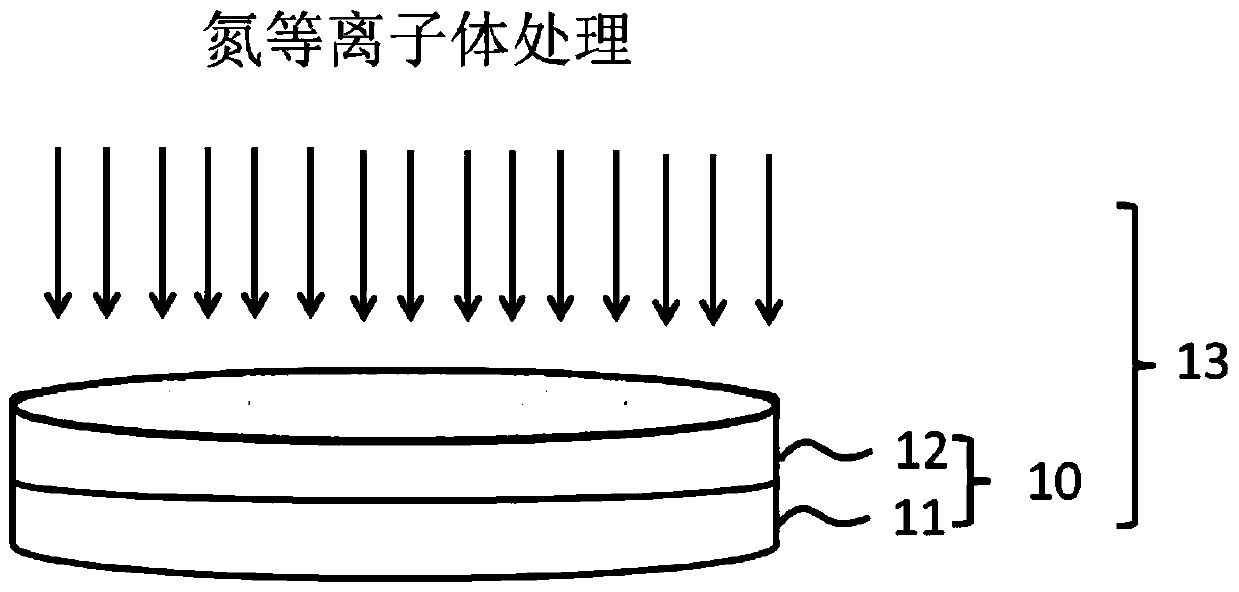

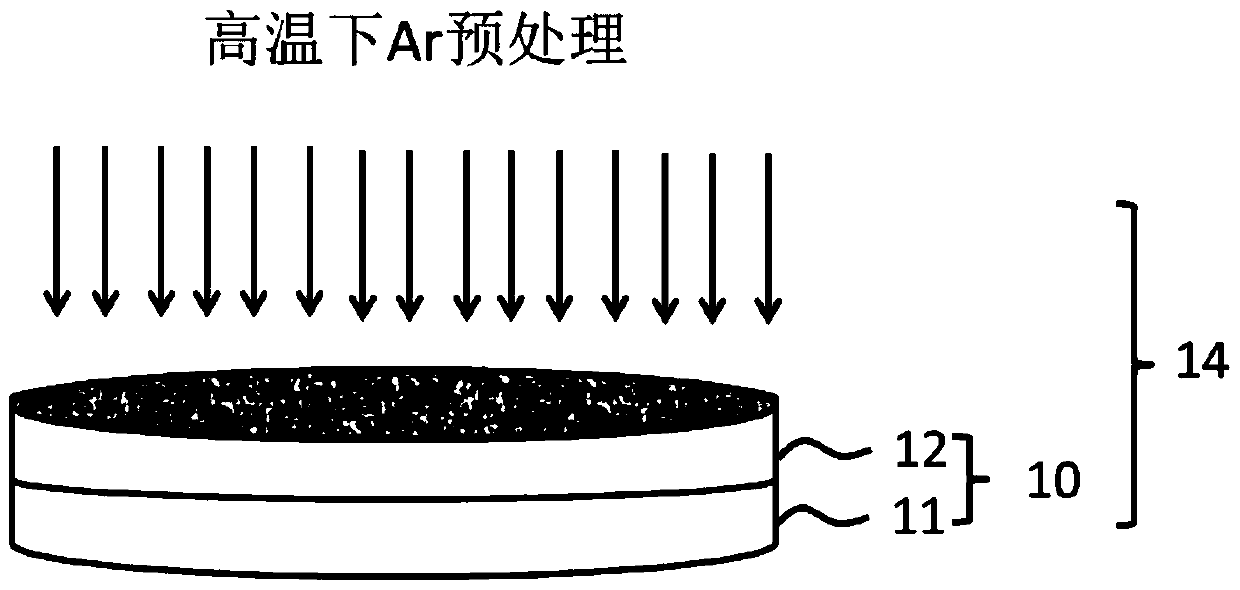

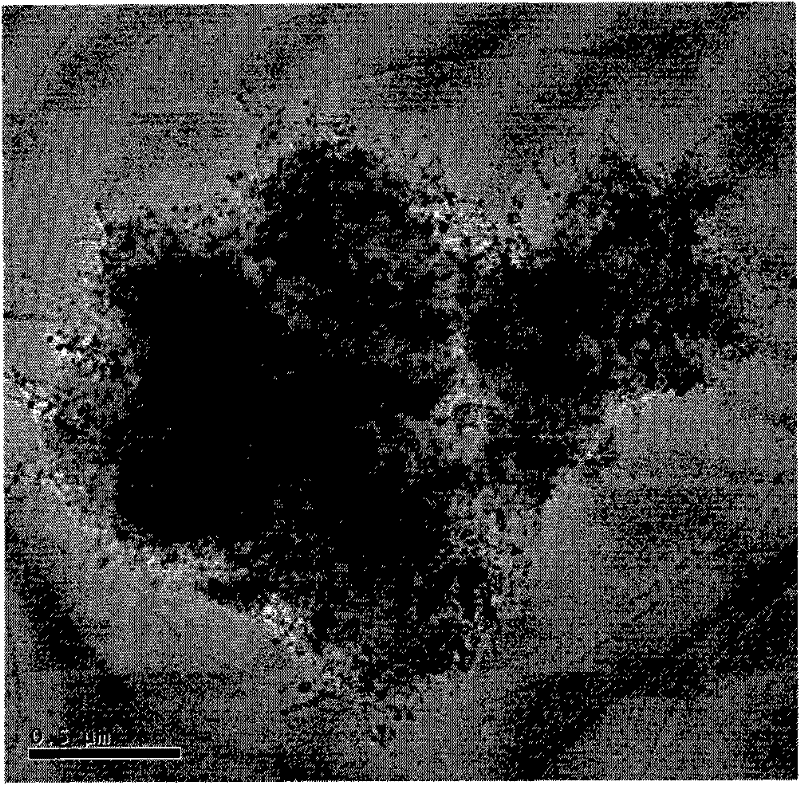

ActiveCN106611700AQuality improvementReduce interface state densitySemiconductor/solid-state device manufacturingOxygen plasmaPre treatment

The invention discloses a preparation method of an oxidization film in a surface of silicon carbide. The method comprises the following steps of 1) cleaning a silicon carbide material (10) containing a substrate (11) and an epitaxial thin film (12); 2) performing oxygen plasma processing on an upper surface of the epitaxial thin film (12); 3) pre-processing a sample (13) obtained in the step 2) in a high temperature; and 4) oxidizing a sample (14) obtained in the step 3) to obtain the oxidization film (15). According to the method, by passivation on the surface of the silicon carbide before formation of the silicon carbide oxidization film, the quality of the silicon carbide oxidization film is improved, and the silicon carbide / silicon dioxide interface state density is reduced; and the method is simple and practical and is suitable for industrial production on a large scale.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Process for after-finishing biological enzymes of ramie yarn and bast fiber cloth

InactiveCN101713149AProcess time savingImprove product qualityBiochemical fibre treatmentVegetal fibresChemistryEnzyme

The invention relates to a process for after-finishing biological enzymes of ramie yarn and bast fiber cloth. The process comprises the following steps of: (1) placing a composite enzyme ingredient in a material cylinder, controlling the pH value, raising the temperature to 50 to 60 DEG C and running the cloth under a liquid level for 30 to 60 minutes; (2) guiding the solution to a main cylinder, controlling the pH value, raising the temperature to 50 to 60 DEG C, running the cloth under the liquid level for 30 to 60 minutes, raising the temperature to 70 to 85 DEG C and running the cloth under the liquid level for 10 to 20 minutes; and (3) placing a film-forming ingredient in the main cylinder, controlling the pH value, raising the temperature to 50 to 60 DEG C to obtain the solution and running the cloth under the liquid level for 30 to 60 minutes. Compared with the prior art, the process for after-finishing the biological enzymes of the ramie yarn and the bast fiber cloth saves energy consumption, simplifies a technological process, prevents the production of toxic substances, remarkably enhances the product quality, achieves a top-quality product rate of over 98 percent and greatly reduces the production cost.

Owner:上海龙之杰企业发展有限公司 +2

Preparation method of silicon carbide surface oxidation film

ActiveCN106611696AQuality improvementReduce interface state densitySemiconductor/solid-state device manufacturingState densitySurface oxidation

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

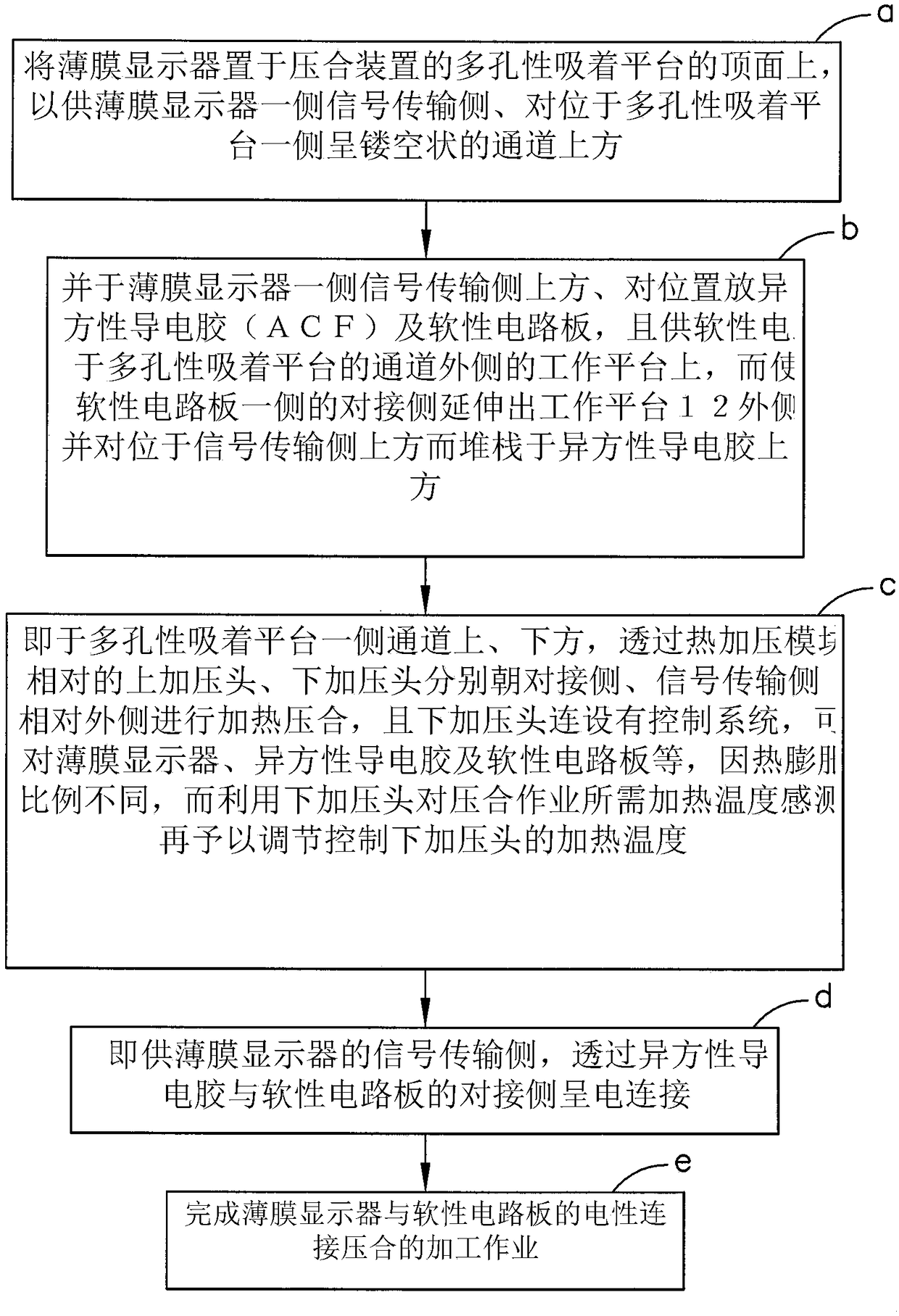

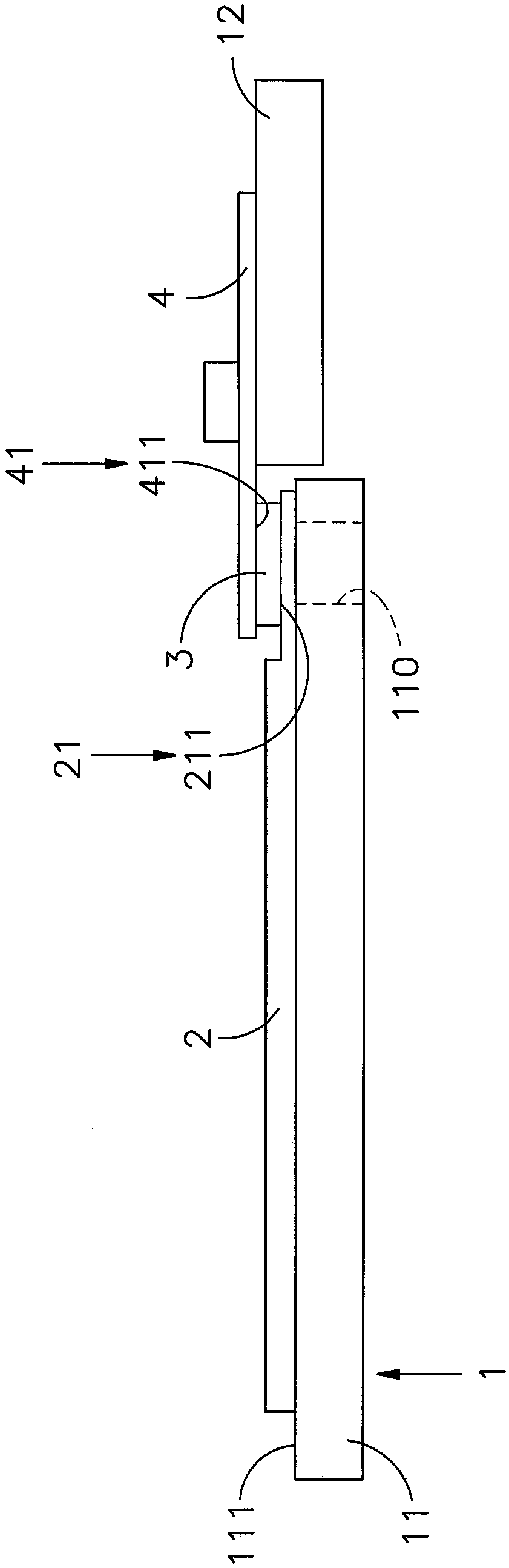

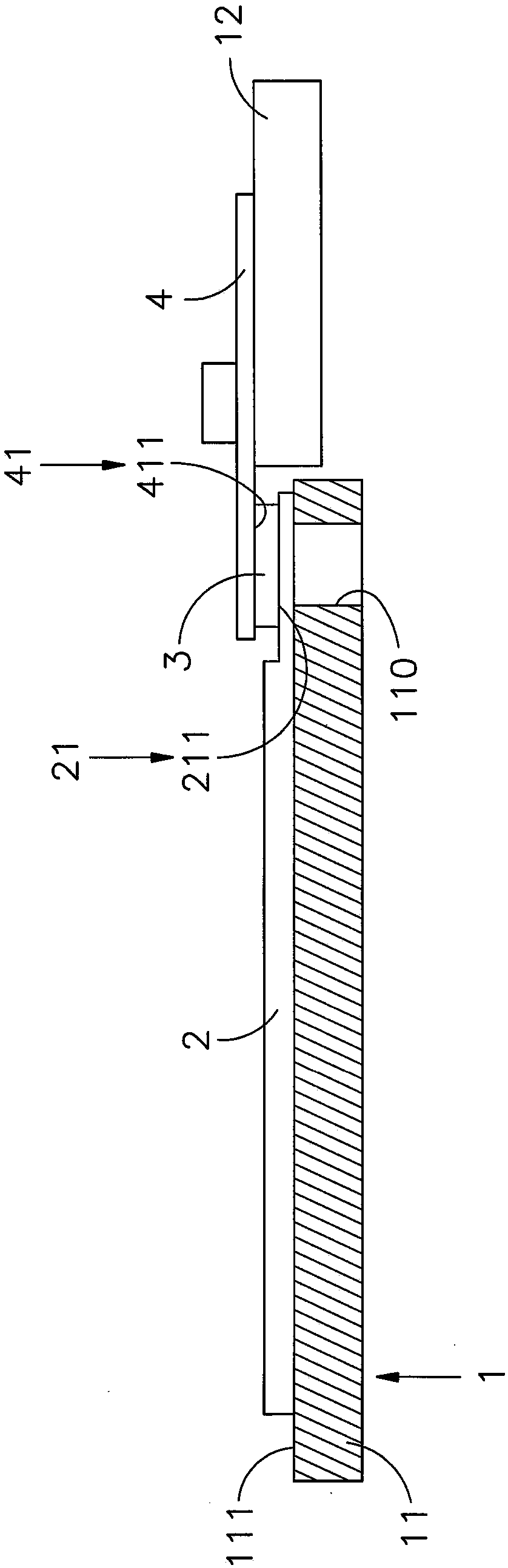

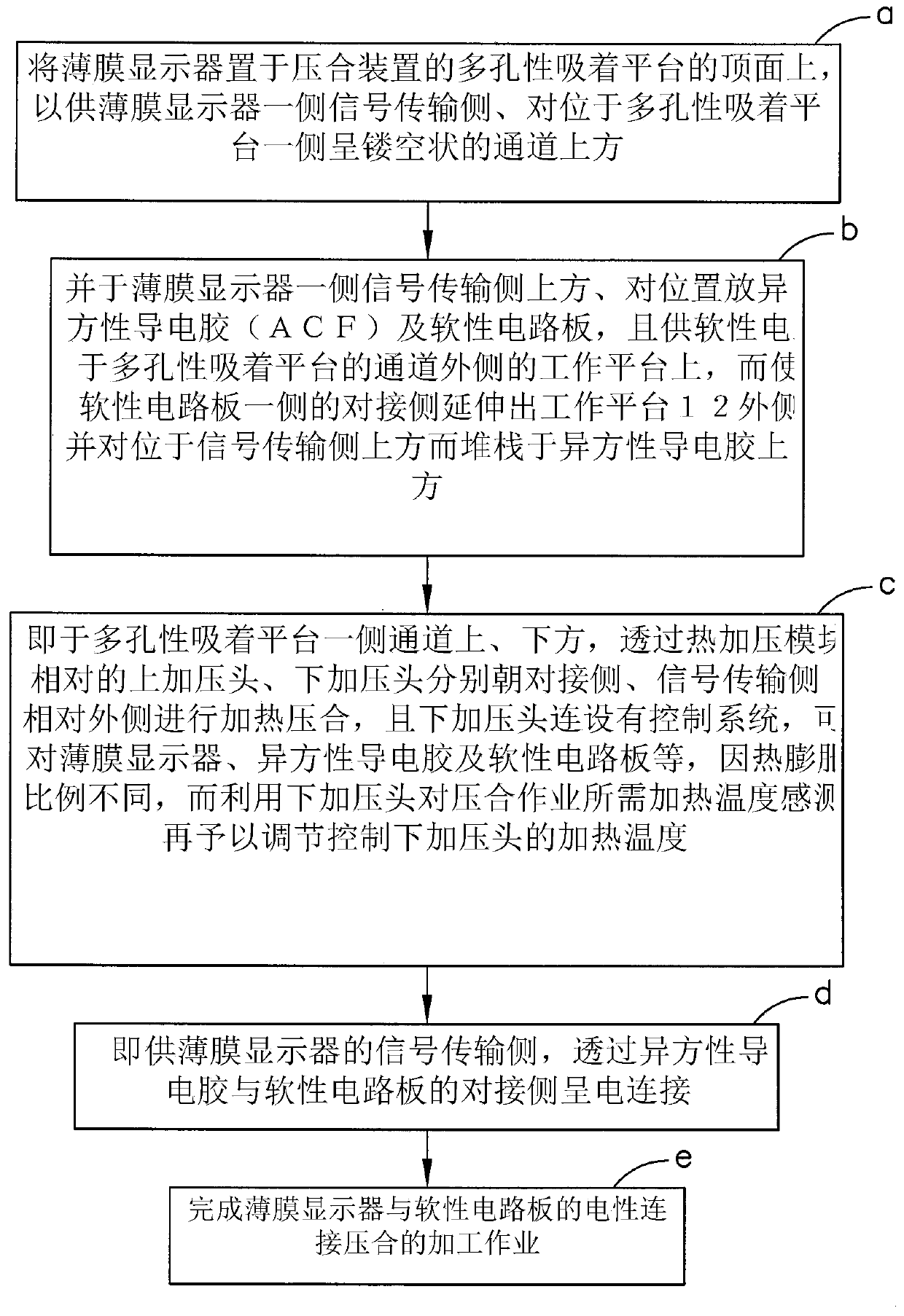

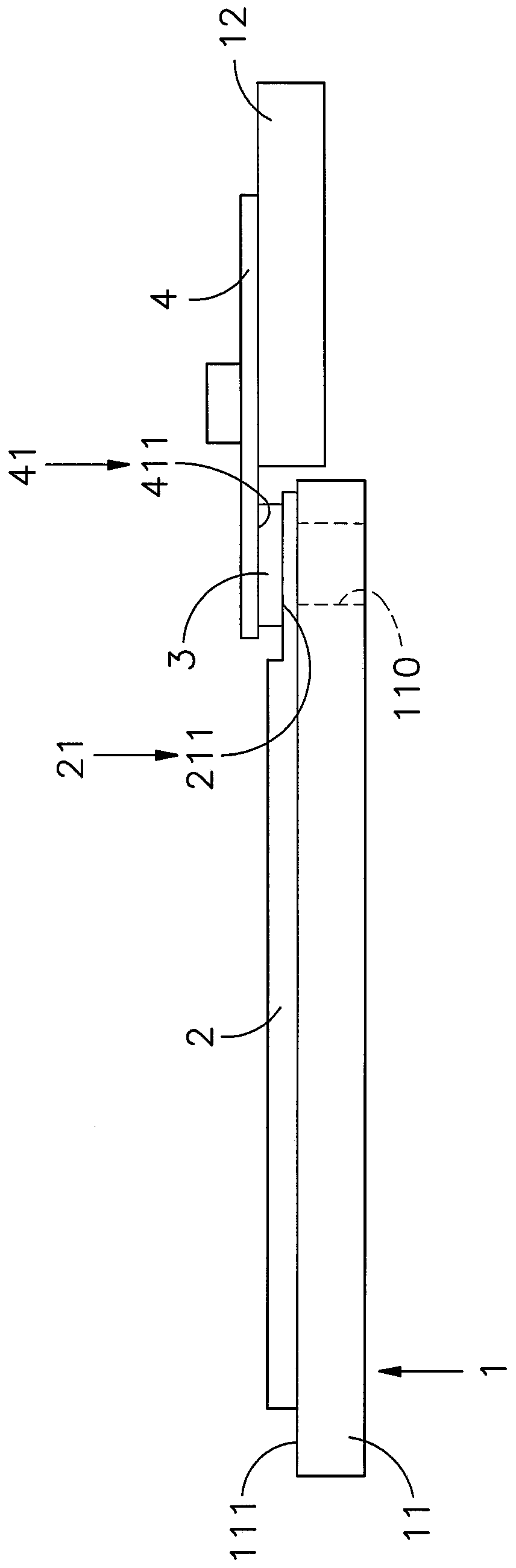

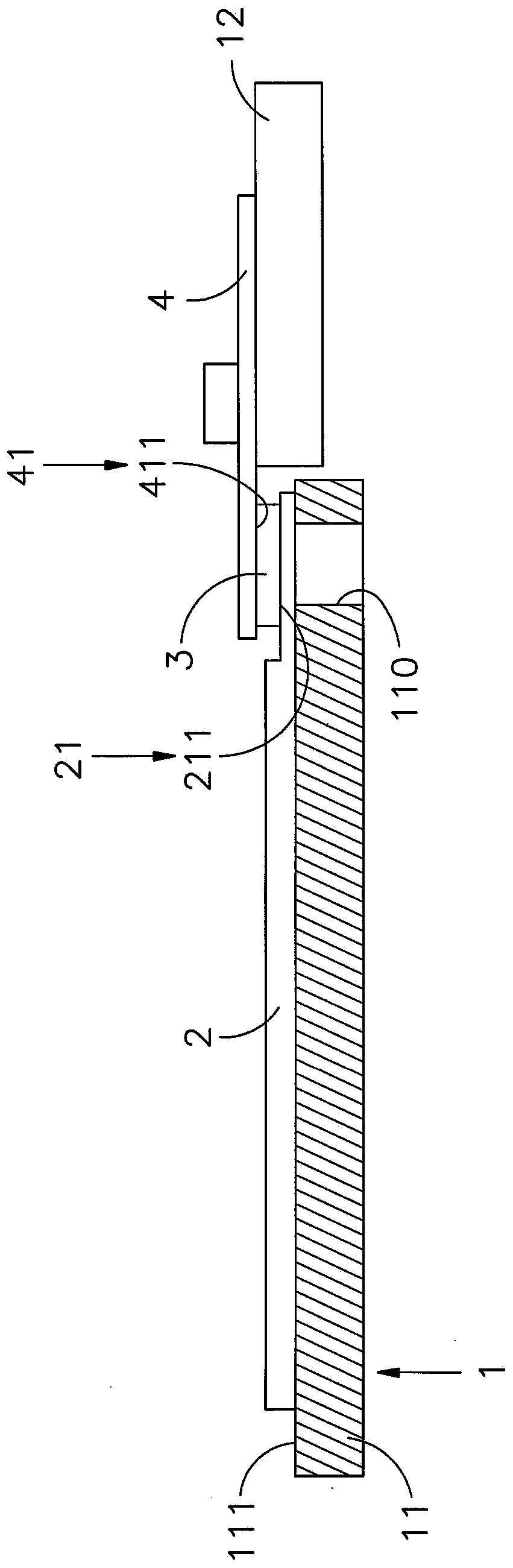

Laminating method of thin-film display and flexible circuit board, and laminating device thereof

InactiveCN109429438AReduce manufacturing costPrecise Thermocompression BondingPrinted circuit assemblingPrinted circuit aspectsAnisotropic conductive adhesiveButt joint

The invention discloses a laminating method of a thin-film display and a flexible circuit board, and a laminating device thereof. A hollow channel is arranged at one side of a porous sorption platformof the laminating device, and a thin-film display is adsorbed at the top of the porous sorption platform through a sorption plane, and a working platform is arranged at the outside of the porous sorption platform of the adjacent channel and used for placing the flexible circuit board, so that one butt-joint side of the flexible circuit board extends to above one signal transmission side of the thin-film display, and anisotropic conductive adhesive is arranged between the signal transmission side and the butt-joint side, namely, thermal pressurizing modules at the upper side and the lower sideof the channel at one side of the porous sorption platform are respectively propped against the butt-joint side and the signal transmission side by using an upper pressurizing head and a lower pressurizing head, thereby heating and laminating the anisotropic conductive adhesive, and achieving the aim of performing thermal lamination at the same or different temperature by adjusting the upper pressurizing head and the lower pressurizing head.

Owner:USUN TECH CO LTD

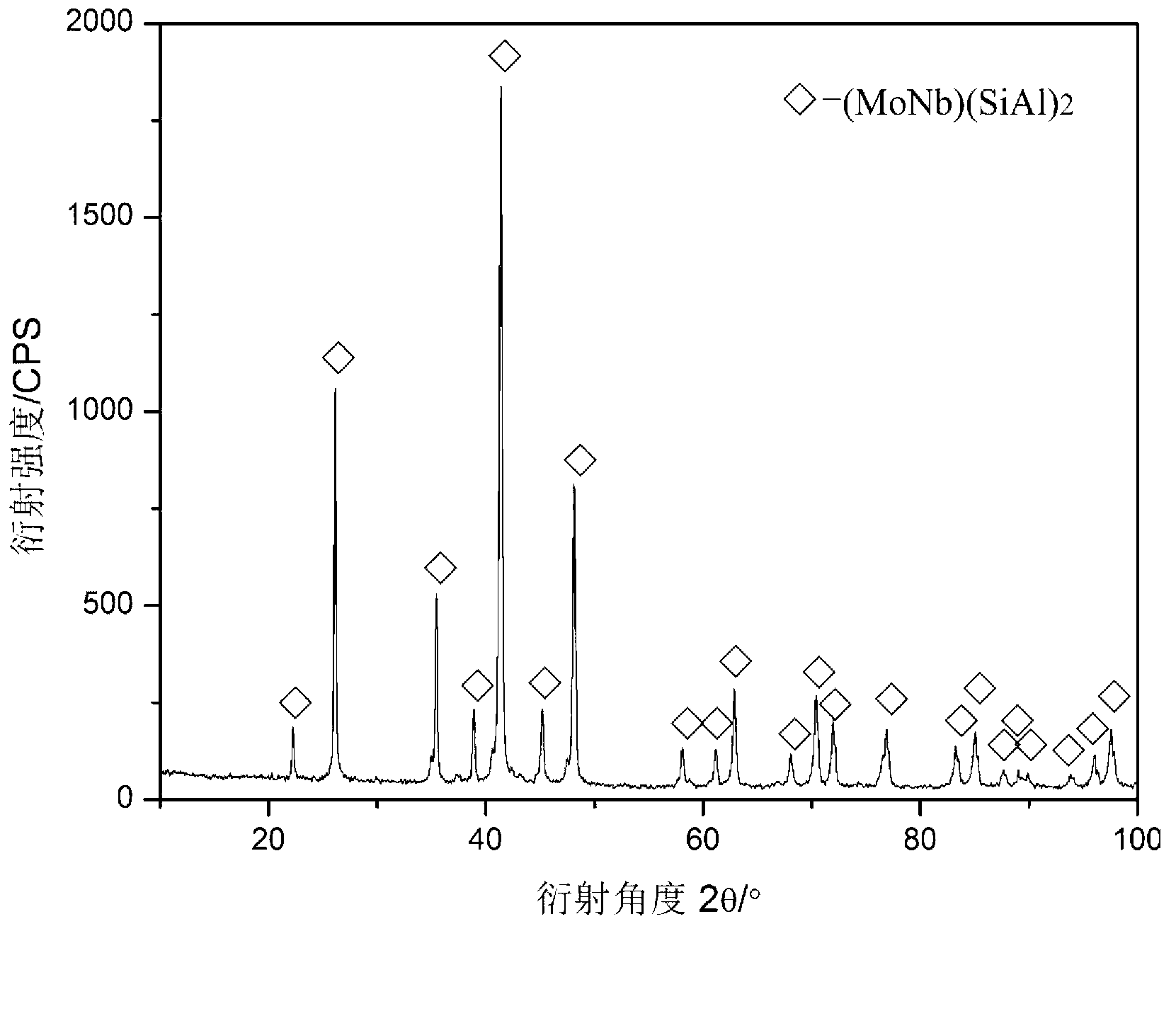

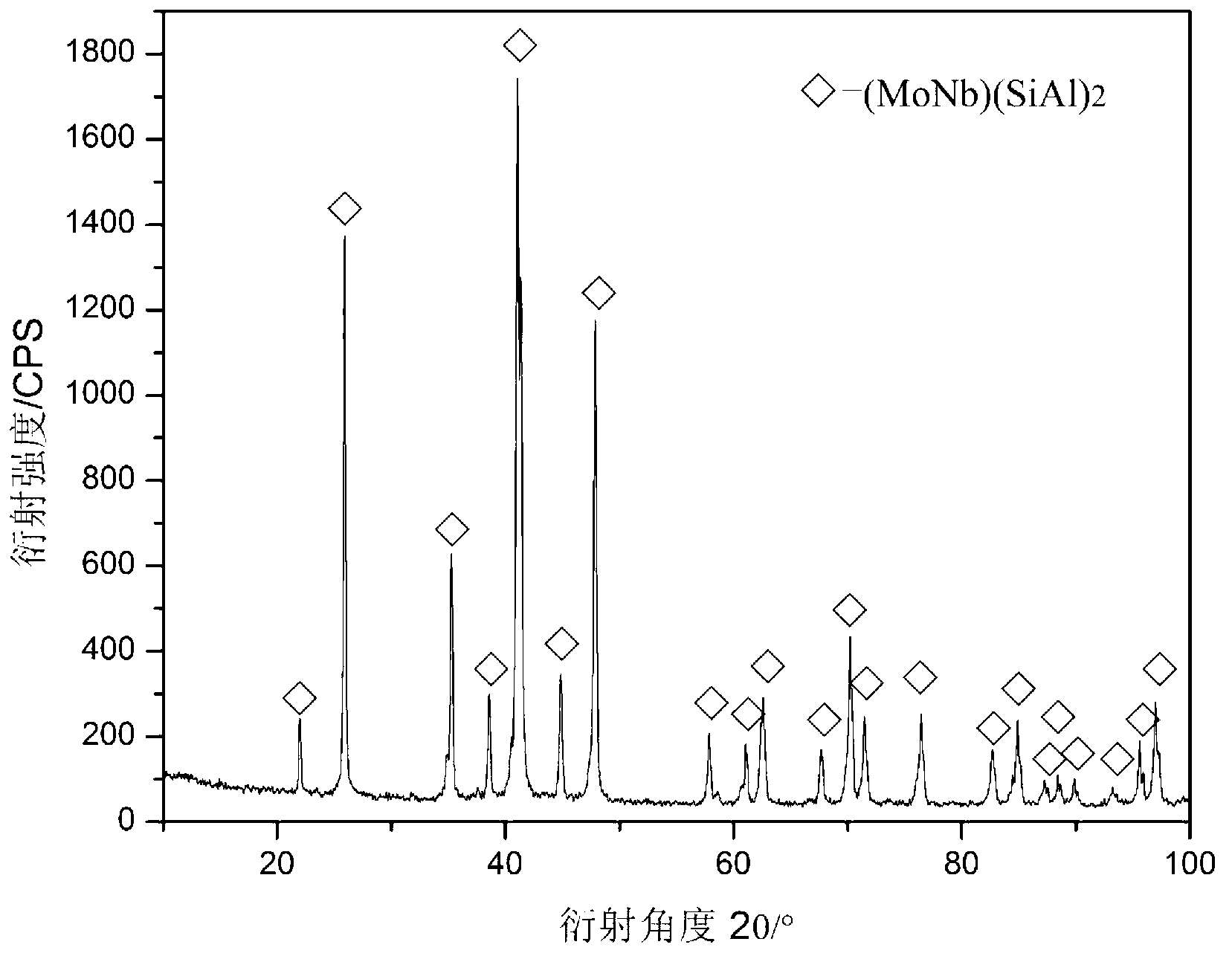

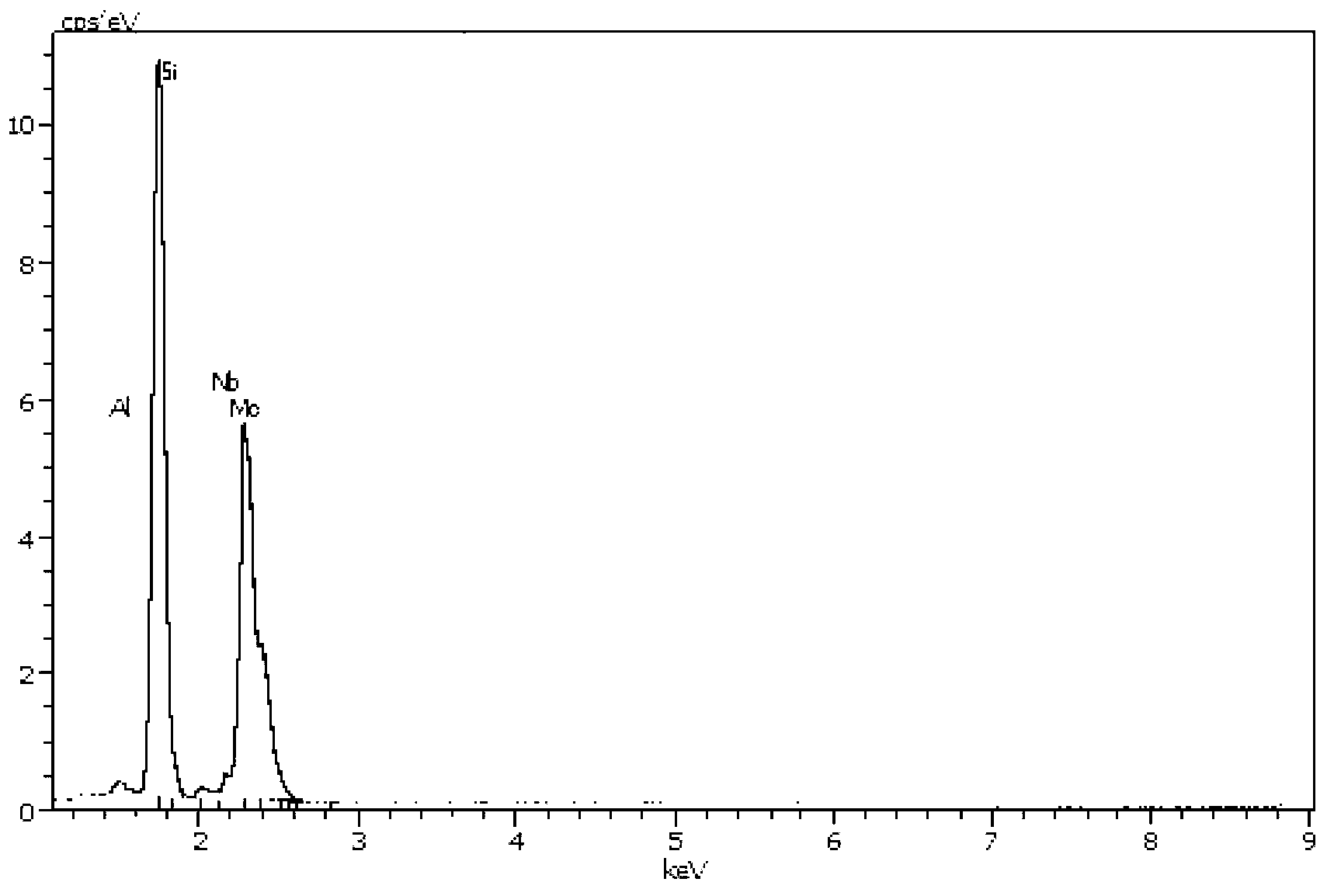

Niobium-aluminum alloying molybdenum disilicide material and preparation method thereof

The invention relates to a niobium-aluminum alloying molybdenum disilicide material and a preparation method thereof, and belongs to the technical field of intermetallic compounds. The chemical formula of the niobium-aluminum alloying molybdenum disilicide material is (Mo1-xNbx)(Si1-yAly)2, wherein X ranges from 0 to 0.15, and Y ranges from 0 to 0.15. The preparation method comprises the following steps of: uniformly mixing molybdenum, niobium, silicon and aluminum powder at a mole ratio of (28.305-33.3):(0-4.995):(56.695-66.7):(0-10.005); then pressing the mixture into a blank; and placing the blank into a combustion synthesis device, and igniting the blank in a protective atmosphere to synthesize the niobium-aluminum alloying molybdenum disilicide material. Compared with the prior art, the niobium-aluminum alloying molybdenum disilicide material disclosed by the invention can be synthesized through a one-step method and has the advantages of good high-temperature strength, simple process and equipment, time and energy conservation, low cost and less pollution.

Owner:CHINA UNIV OF MINING & TECH

Product by spraying with high molecular materials by dry method and glazing at low temperature and production process thereof

The invention provides a product by spraying with high molecular materials by a dry method and glazing at low temperature and a production process thereof. The product is obtained by spraying with glazing powder by a dry method and glazing at low temperature on surface of a balled iron blank. The glazing powder is made from the following parts of raw materials by weight: substrate materials: 30-50 parts of resin, 2-8 parts of silicon dioxide and 10-20 parts of titanium dioxide; auxiliary materials: 2-9 parts of stainless steel powder, 3-8 parts of iron powder, 2-7 parts of calcium carbonate and 5-12 parts of magnesium carbonate; and additives: 0.5-3.5 parts of a curing accelerator, 1-3 parts of a leveling agent, 1-3 parts of a colorant, 1-3 parts of a luster-enhancing agent and 1-3 parts of an anticorrdant. The production process thereof comprises the following steps: fabricating the balled iron blank, pickling, degreasing, surface conditioning, phosphating, spraying by the dry method, pyrographing, spraying with fluorescent liquid and adding a steel ring to obtain a finished product. The sintering temperature of the production process is 160-200 DEG C, porcelain surface of the product is flat and smooth and is bright like a mirror, and rich in designs and colors; avoids porcelain shedding during collision and beating, and has long service life.

Owner:河南金丹搪瓷有限公司

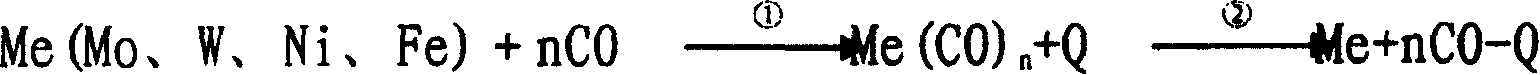

Method for preparing solid self-lubricating material

The present invention relates to a preparation method of solid self-lubricating material. Said preparation method includes the following steps: firstly, using carbon oxide and metal and making them produce reaction under the action of a certain temperature and pressure to form carbonyl metal compound, then making the carbonyl metal compound undergo the process of thermo-cracking treatment to obtain the metal powder with required size, and making the metal powder be deposited on the surface of solid lubricating agent to coker said surface so as to form compact solid lubricating agent microspheres, making said microspheres be mixed with metal and alloy powder according to a certain ratio to obtain solid self-lubricating raw material, finally press-forming by utilizing isostatic cool pressing technique and sintering by means of vacuum-hydrogen sintering process so as to obtain the invented product. Besides, said invention also provides its application range.

Owner:BEIJING CISRI GAONA TECH

Method for extracting superoxide dismutase from cattle and sheep blood largly industrially and blade type agitator applied to same

InactiveCN101921736ASave heatReduce process costRotary stirring mixersMixer accessoriesUltrafiltrationChemistry

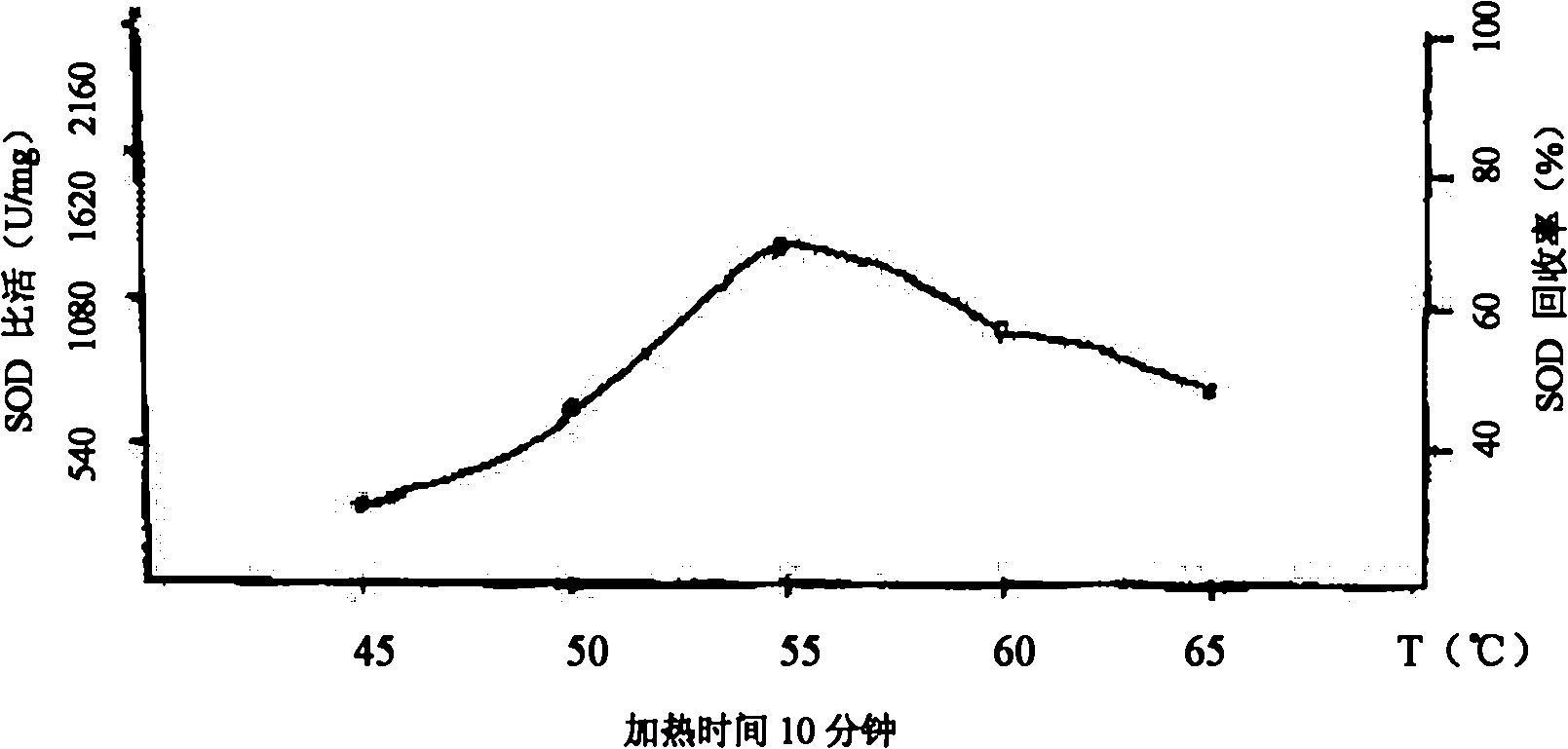

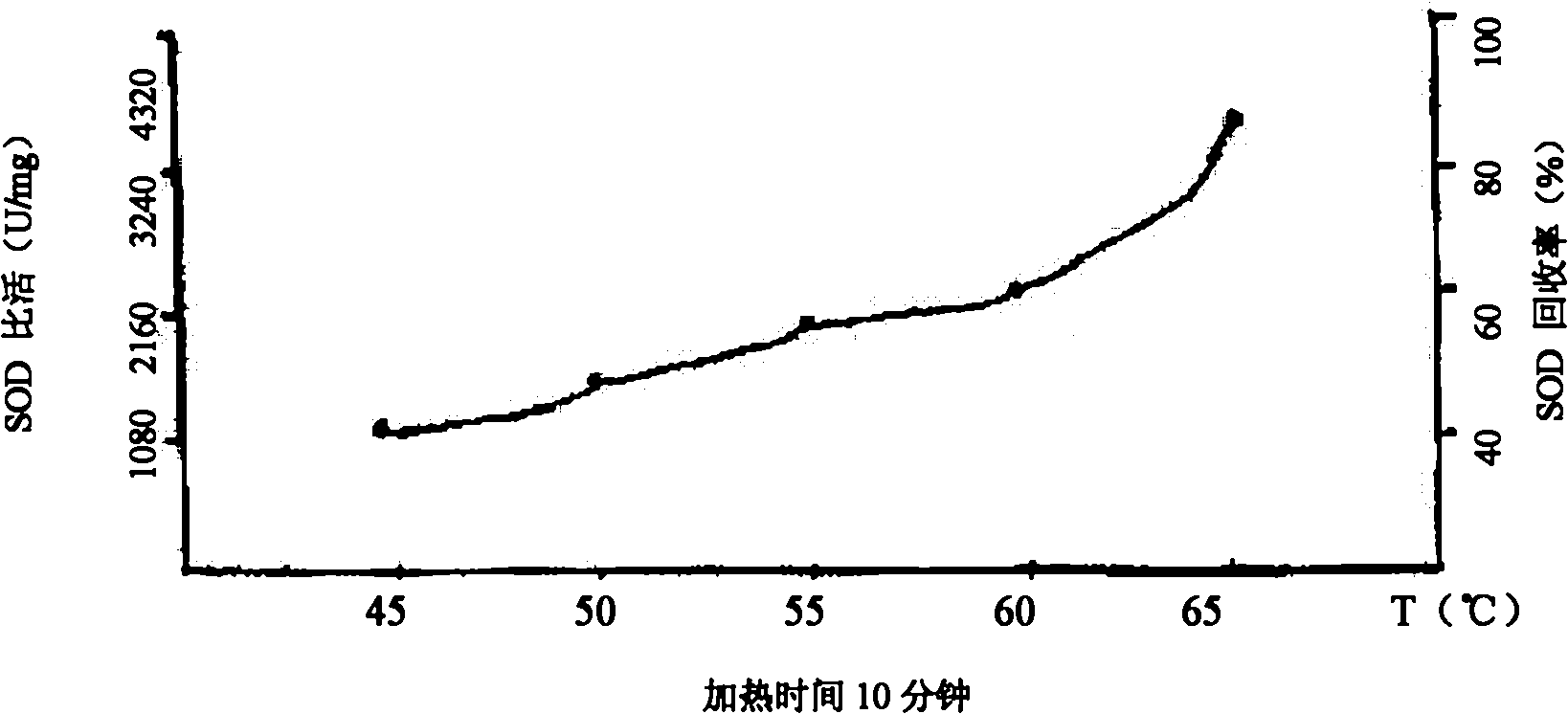

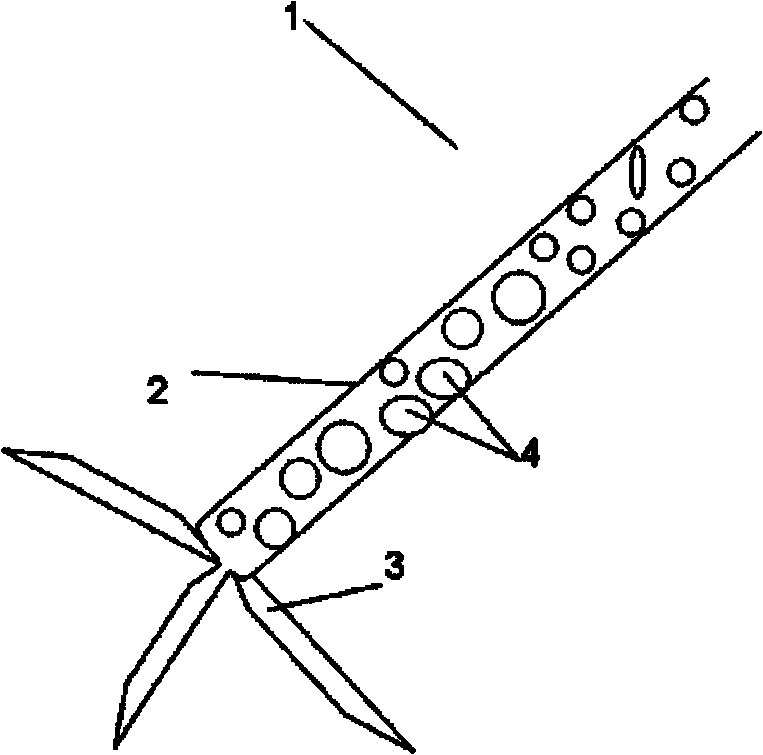

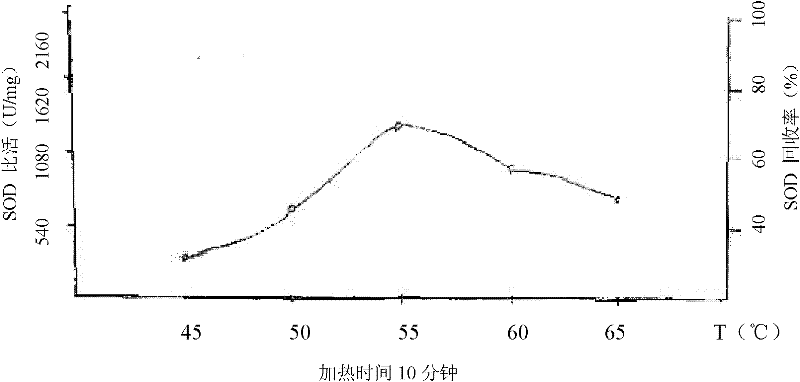

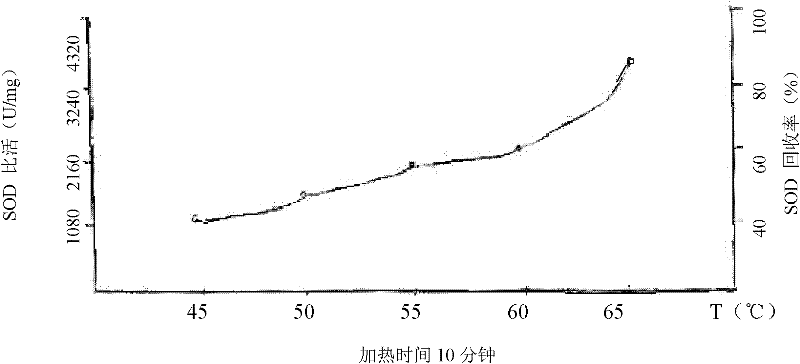

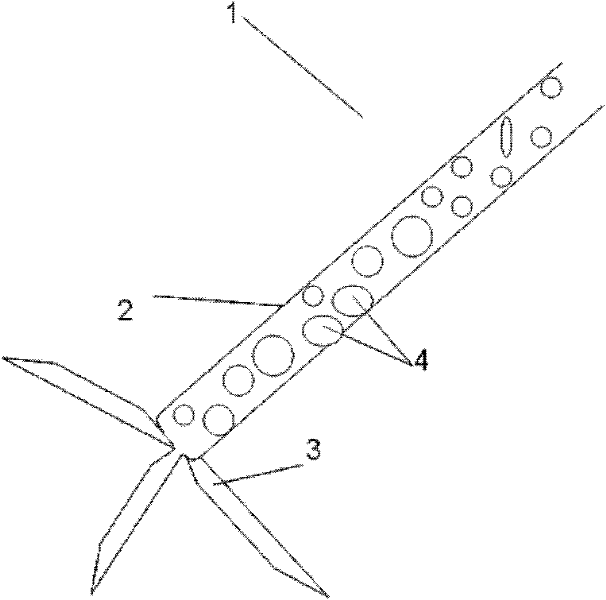

The invention discloses a method for extracting superoxide dismutase from cattle and sheep blood largly industrially, comprising the following steps of: carrying out the production steps of anticoagulation, hypotonic hemolysis, ultrafiltration, fast temperature rise and reduction, sedimentation, three-stage temperature treatment, salting-out, ultrafiltration, concentration, freeze drying, and the like on fresh cattle or sheep blood so as to simultaneously obtain two groups of superoxide dismutase finished products which are slightly different in specific activity and purity, wherein the fast temperature rise and reduction is realized through an agitator with a heat / cold source; the first-stage temperature treatment is carried out at 45-55 DEG C, the second-stage temperature treatment is carried out at 55-60 DEG C, and the third-stage temperature treatment is carried out at 60-65 DEG C. Compared with the prior art, the invention has the advantages of simple process, short production period, high yield coefficient and specific activity of the products, stable quality, low cost, excellent economic benefit, and the like.

Owner:云南光华亚南生物科技有限公司

Bio-enzymatic desizing and fermentation one-bath process of pure cotton and cotton-containing blended denim garments

ActiveCN104452315BReduced desizingNo generationBiochemical fibre treatmentDry-cleaning apparatus for textilesDenimHardness

Owner:FIBER CHEM BIOLOGICAL CHEM

One-step preparation of carbon nitride/titanium dioxide heterojunction photocatalyst by electrospinning

ActiveCN107456987BLow utilization efficiencyEasy to captureWater/sewage treatment by irradiationWater treatment compoundsPtru catalystPyrrolidinones

The invention belongs to the technical field of photocatalysts for organic sewage degradation, and particularly relates to a method for preparing carbon nitride / titanium dioxide heterojunction photocatalysts by one-step electrospinning. The heterojunction photocatalyst is prepared by a one-step electrospinning method. Specifically, melamine or guanidine hydrochloride or urea is added to a mixed solution containing glacial acetic acid, tetrabutyl titanate, polyvinylpyrrolidone and an organic solvent, and electrospinning is performed. The carbon nitride / titanium dioxide heterojunction photocatalyst is prepared by the process and high temperature calcination treatment. The prepared photocatalyst has a good heterostructure and excellent photocatalytic degradation performance of organic sewage, which simplifies the preparation process of carbon nitride / titanium dioxide heterojunction photocatalyst, and the process is simple and time-saving. It has better application prospects.

Owner:湖北省亨德利医疗器械有限公司

Process for after-finishing biological enzymes of ramie yarn and bast fiber cloth

InactiveCN101713149BNo generationAchieve emission reductionBiochemical fibre treatmentVegetal fibresYarnToxic material

Owner:上海龙之杰企业发展有限公司 +2

A double buffer layer lateral epitaxial growth method for improving LED brightness

InactiveCN104900774BReduce dislocationReduce orientation differencesSemiconductor devicesQuantum wellSulfate

Owner:西安明德理工学院

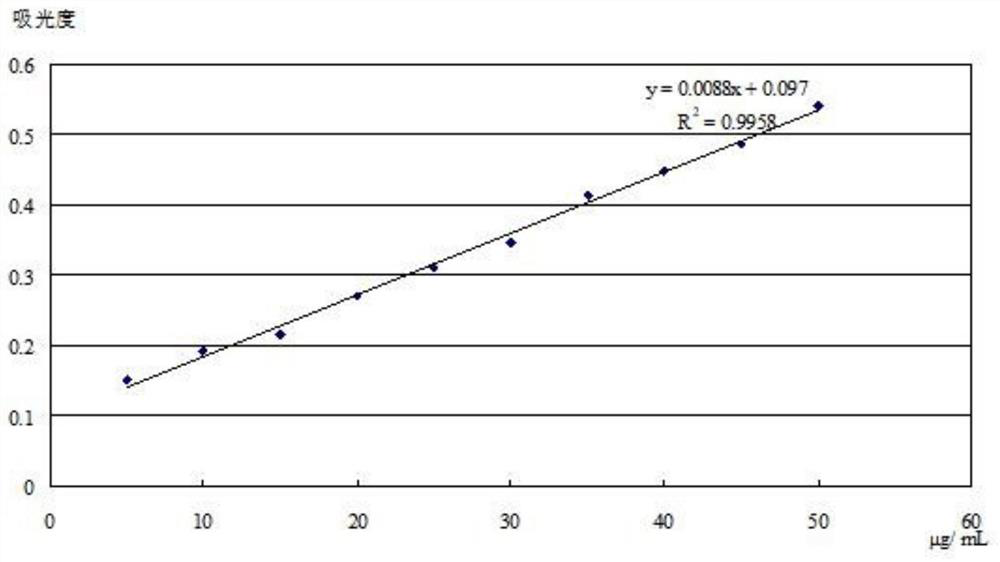

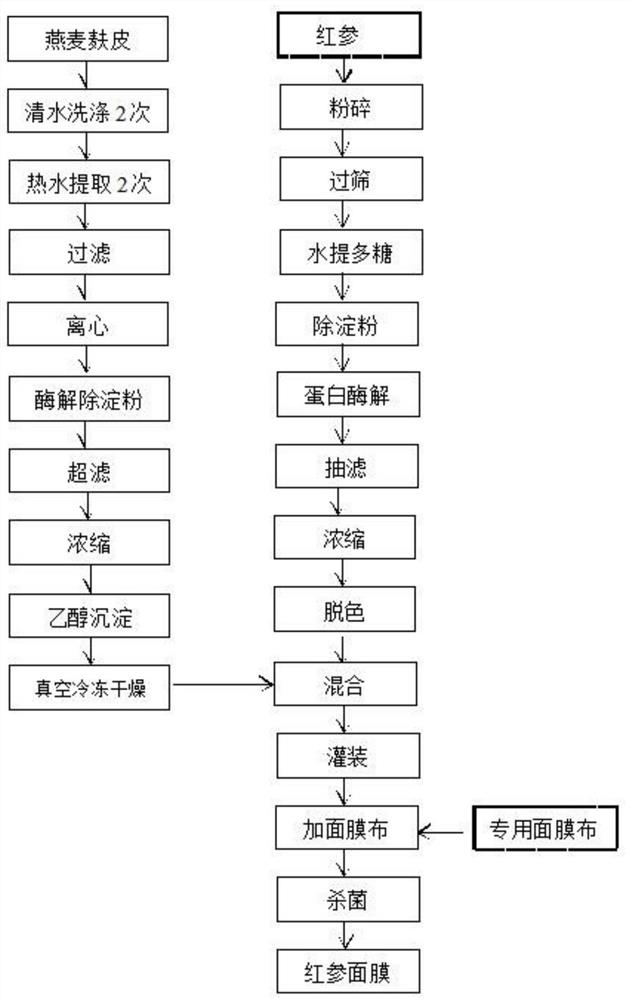

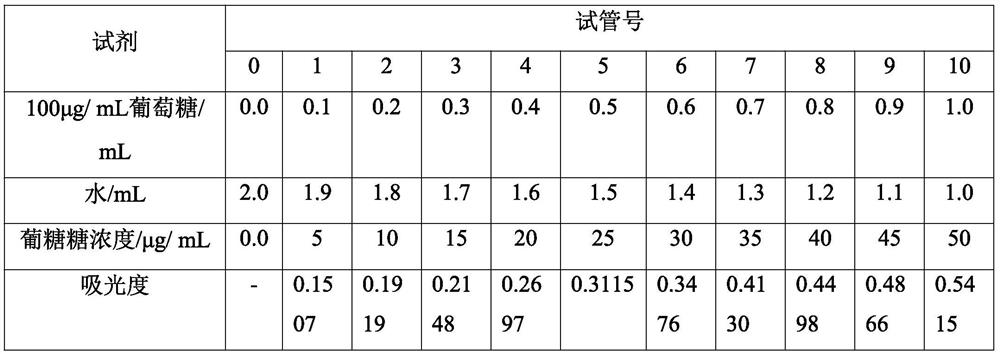

A kind of preservative-free red ginseng facial mask and preparation method thereof

ActiveCN108619001BNo side effectsProtects against UV damageCosmetic preparationsToilet preparationsBeta d glucanSkin cell

The invention discloses a preservative-free red ginseng facial mask and a preparation method thereof; the facial mask uses red ginseng polysaccharide extract and oat beta glucan as functional components, acts on the skin, and has the functions of reducing aging, reducing wrinkles, moisturizing, Promote the growth of fibroblasts and the synthesis of collagen. Red ginseng and oat bran are used as raw materials for preparation, red ginseng polysaccharide and oat β-glucan are extracted respectively, oat β-glucan is added to the red ginseng polysaccharide extract in an appropriate proportion, and processed into red ginseng polysaccharide after filling and sterilization. See mask products. The functional ingredients of this product are derived from natural raw materials, without adding any preservatives and additives, and can enhance the activity of skin cells. It is a red ginseng mask product with good moisturizing effect and preventing skin aging.

Owner:SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

Method for producing sodium carboxymethyl cellulose (CMC) with low sodium by utilizing ultrasound

The invention discloses a method for producing sodium carboxymethyl cellulose (CMC) with low sodium by utilizing ultraphonic, comprising the following steps: adding an acid solution into a CMC raw material, and carrying out ultrasonic processing; reacting under the set temperature, separating to remove fractional centrifugation liquid, adding alkai, and carrying out ultrasonic processing; and dewatering, drying and smashing to obtain the product. By the method of the invention, the CMC with low sodium, which has high quality, can be obtained. The invention has the characteristics of energy conservation, time saving, simple and convenient operation, capability of obtaining high-performance product and stable batch quality.

Owner:SOUTH CHINA UNIV OF TECH

Method for extracting superoxide dismutase from cattle and sheep blood largly industrially and blade type agitator applied to same

InactiveCN101921736BEasy to removeDifficult to penetrateRotary stirring mixersMixer accessoriesBiotechnologyDismutase

The invention discloses a method for extracting superoxide dismutase from cattle and sheep blood largly industrially, comprising the following steps of: carrying out the production steps of anticoagulation, hypotonic hemolysis, ultrafiltration, fast temperature rise and reduction, sedimentation, three-stage temperature treatment, salting-out, ultrafiltration, concentration, freeze drying, and thelike on fresh cattle or sheep blood so as to simultaneously obtain two groups of superoxide dismutase finished products which are slightly different in specific activity and purity, wherein the fast temperature rise and reduction is realized through an agitator with a heat / cold source; the first-stage temperature treatment is carried out at 45-55 DEG C, the second-stage temperature treatment is carried out at 55-60 DEG C, and the third-stage temperature treatment is carried out at 60-65 DEG C. Compared with the prior art, the invention has the advantages of simple process, short production period, high yield coefficient and specific activity of the products, stable quality, low cost, excellent economic benefit, and the like.

Owner:云南光华亚南生物科技有限公司

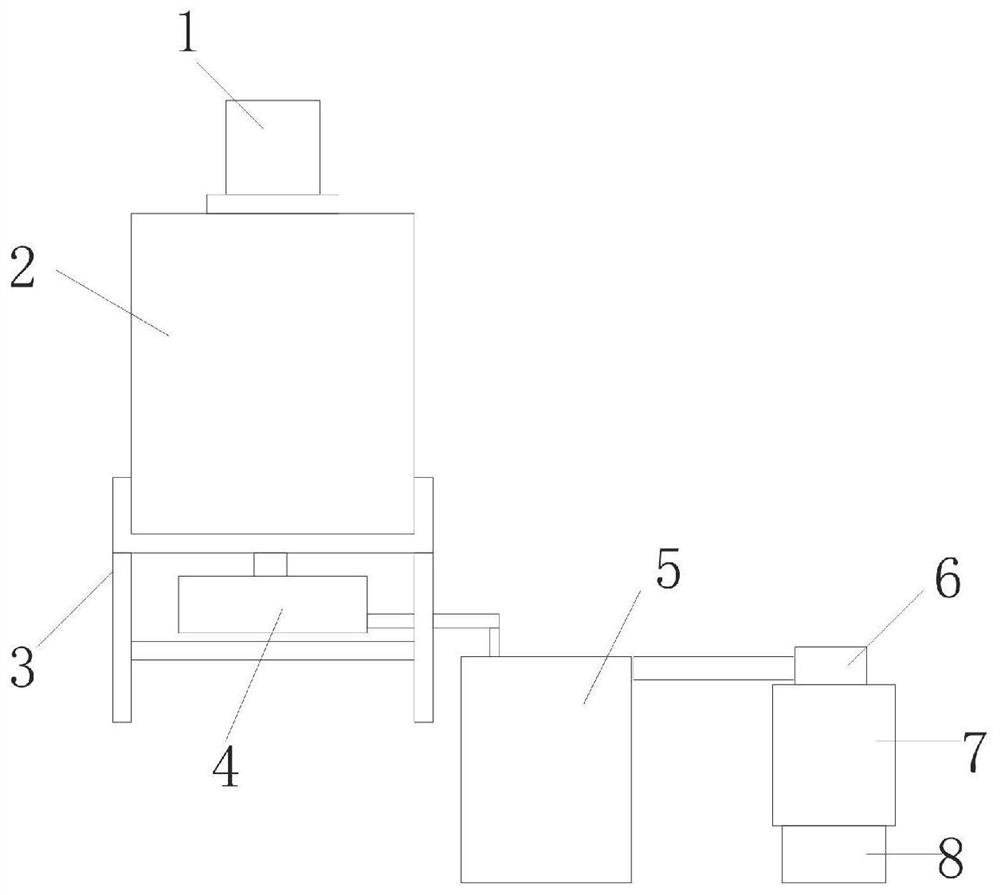

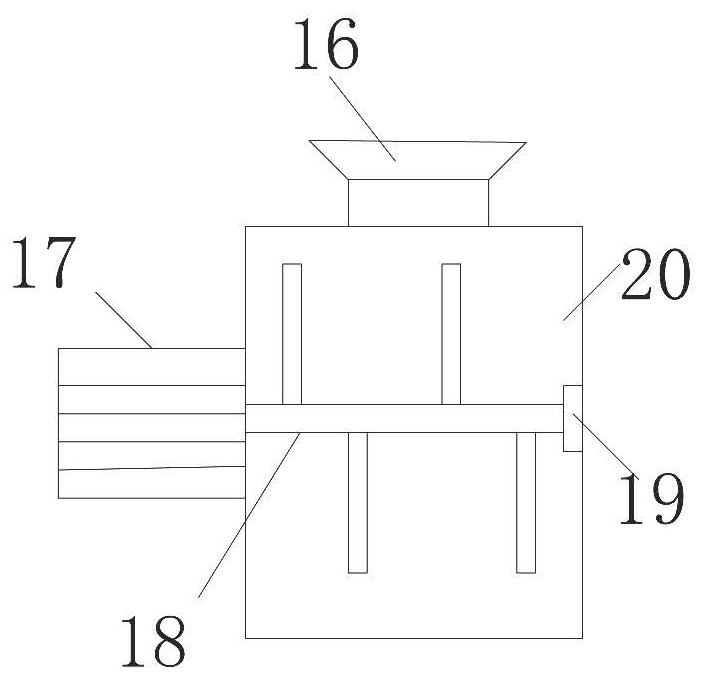

Extraction system containing supercritical extraction kettle

PendingCN113416607AIncrease productionAvoid wastingEssential-oils/perfumesSolid solvent extractionPhysical chemistryAnalytical chemistry

The invention belongs to the technical field of critical extraction, and discloses an extraction system containing a supercritical extraction kettle, An extrusion structure is fixed on the upper side of a supporting frame, and a masher is fixed on the upper side of the extrusion structure; a filtering structure is fixed to the supporting frame and connected with the extrusion structure; the filtering structure is connected with a microwave extractor through a guide pipe, the microwave extractor is connected with a collecting box through a guide pipe, the collecting box is connected with a condensing structure, and the collecting box is arranged at the lower end of the condensing structure; and the microwave extractor is provided with an inner extraction cavity, a liquid inlet, a reflux inlet, a stirring device, a microwave heating cavity, a discharging device, a microwave source and a microwave suppressor. Materials are put into the masher to be mashed, so that the extraction yield is increased, and a large amount of waste of the materials is avoided. The materials are extruded through the extrusion structure, juice is generated, and the corresponding yield is increased.

Owner:浙江邦宁尔制药有限公司

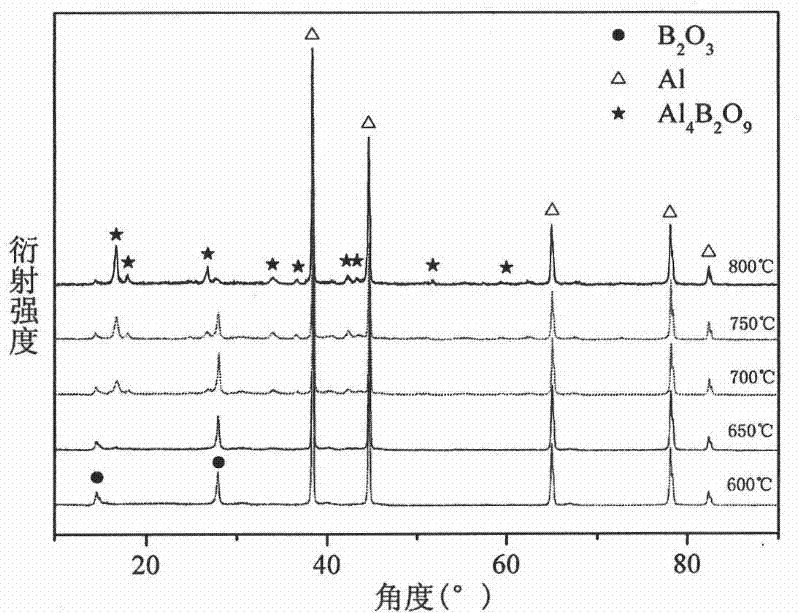

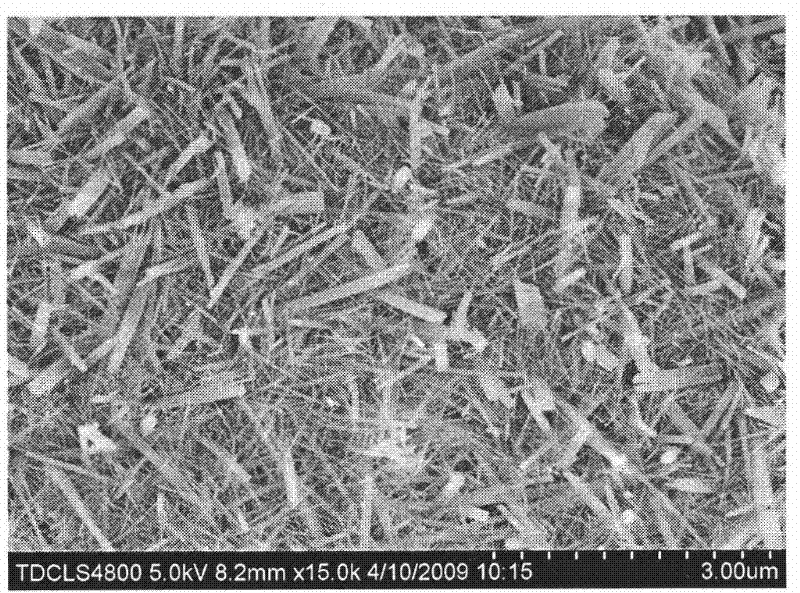

Method for growing and preparing aluminium borate whisker/ aluminium composite powder on aluminium powder surface in situ

The invention discloses a method for growing and preparing aluminium borate whisker / aluminium composite powder on aluminium powder surface in situ, belonging to the technology of ceramic whisker / metal composite powder materials. The method process comprises the following steps: adding aluminium powder and boric acid powder by mass into a stainless steel jar to be subjected to ball milling to prepare ball milling pre-prepared mixed powder; spreading the ball milling pre-prepared mixed powder in an alumina boat; putting the alumina ark into a quartz heating furnace; and under the protection ofargon, calcining at the temperature of 650-800 DEG C to prepare the product of aluminium borate whisker / aluminium composite powder. The method has the advantage of simple technology and is easy to realize mass production; the size of aluminium borate whisker growing in the aluminite powder matrix is even, and the aluminium borate whisker has favourable associativity with the aluminite powder matrix.

Owner:TIANJIN UNIV

Lamination method and lamination device for film display and flexible circuit board

InactiveCN109429438BReduce manufacturing costPrecise Thermocompression BondingPrinted circuit assemblingPrinted circuit aspectsAnisotropic conductive adhesiveFlexible circuits

The invention relates to a lamination method and lamination device of a thin film display and a flexible circuit board. The porous adsorption platform of the lamination device is provided with a hollow channel on one side, and the top absorbs the thin film display through the adsorption plane, and The outer side of the porous adsorption platform of the adjacent channel is provided with a working platform for placing the flexible circuit board, so that the docking side of the flexible circuit board extends to the top of the signal transmission side on the side of the film display, and then on the signal transmission side, docking The anisotropic conductive adhesive is set between the sides, that is, the upper and lower pressure heads of the thermal pressurization module on the upper and lower channels of the adsorption platform are respectively held against the docking side and the anisotropy on the signal transmission side by using porosity. The conductive adhesive is heated and pressed to achieve the purpose of adjusting the upper pressure head and the lower pressure head to perform heat and pressure at the same or different temperatures.

Owner:USUN TECH CO LTD

A kind of preparation method of silicon carbide surface oxide film

ActiveCN106611696BQuality improvementReduce interface state densitySemiconductor/solid-state device manufacturingNitrogen plasmaSurface oxidation

The invention discloses a preparation method of a silicon carbide surface oxidation film. The method comprises the following steps that 1) a silicon carbide material (10) including a substrate (11) and an epitaxial film (12) is cleaned; 2) nitrogen plasma processing is carried out on the upper surface of the epitaxial film (12); 3) a sample (13) obtained in the step 2) is preprocessed by argon at high temperature; and 4) a sample (14) obtained in the step 3) is oxidized to obtain the oxidation film (15). Passivation is carried out on the surface of silicon carbide before that the silicon carbide oxidation film is formed, the quality of the silicon carbide oxidation film is improved, the interface state density of silicon carbide / silica is reduced, and the method is easy to carry out, and suitable for large-scale industrial production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Method for preparing carbon nanotube/magnesium composite powder by nickel catalytic in-situ chemical vapor deposition

The invention discloses a method for preparing carbon nanotube / magnesium composite powder by nickel catalytic in-situ chemical vapor deposition, and the process of the method comprises the following steps: adding nickel nitrate hexahydrate and magnesium powder into anhydrous ethanol, and preparing a precursor of a nickel / magnesium catalyst through the thermal decomposition method; and placing theprecursor of the nickel / magnesium catalyst in a quartz reaction tube, increasing the temperature to the reduction temperature under the protection of argon, introducing hydrogen for reduction, and then taking methane as carbon source gas and taking the argon as carrier gas for preparing the carbon nanotube / magnesium composite powder by using the chemical vapor deposition method at the growth temperature. The method has simple and time-saving process, the in-situ growth on the carbon nanotube / magnesium powder has good dispersion, and a carbon nanotube further has narrow tube diameter and uniform size, thereby being particularly applicable to preparing carbon nanotube-reinforced magnesium matrix composites.

Owner:TIANJIN UNIV

A kind of preparation method of silicon carbide surface oxide film

ActiveCN106611700BQuality improvementReduce interface state densitySemiconductor/solid-state device manufacturingOxygen plasmaPre treatment

The invention discloses a preparation method of an oxidization film in a surface of silicon carbide. The method comprises the following steps of 1) cleaning a silicon carbide material (10) containing a substrate (11) and an epitaxial thin film (12); 2) performing oxygen plasma processing on an upper surface of the epitaxial thin film (12); 3) pre-processing a sample (13) obtained in the step 2) in a high temperature; and 4) oxidizing a sample (14) obtained in the step 3) to obtain the oxidization film (15). According to the method, by passivation on the surface of the silicon carbide before formation of the silicon carbide oxidization film, the quality of the silicon carbide oxidization film is improved, and the silicon carbide / silicon dioxide interface state density is reduced; and the method is simple and practical and is suitable for industrial production on a large scale.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com