Preparation method of silicon carbide surface oxidation film

A surface oxidation and silicon carbide technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of SiC MOSFET device performance degradation, complex oxidation mechanism, etc., to reduce interface state density, simple process, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Example 1

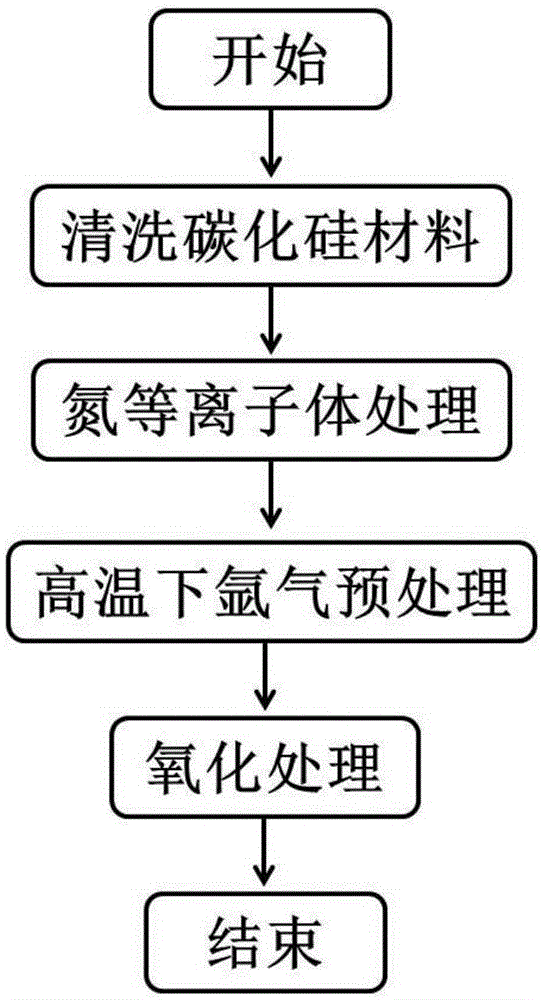

[0031] A method for preparing an oxide film on a silicon carbide surface, the method comprising the steps of:

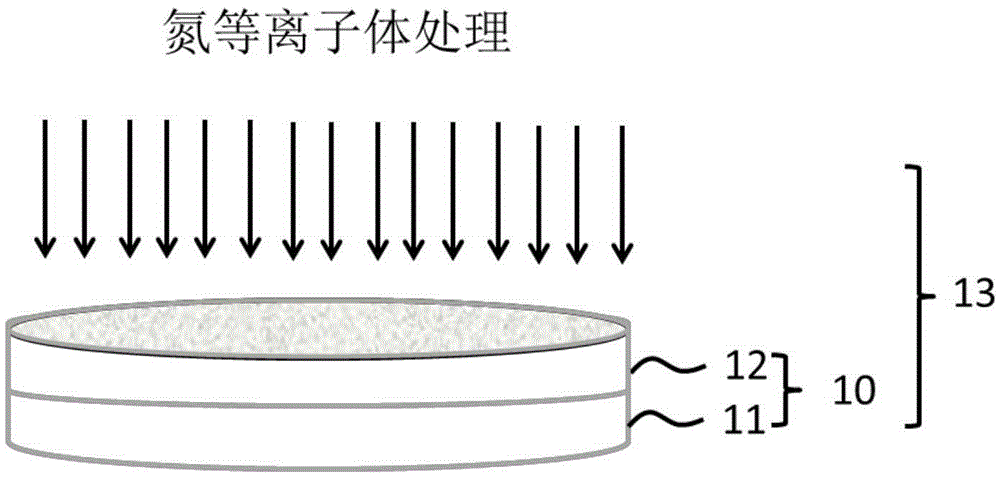

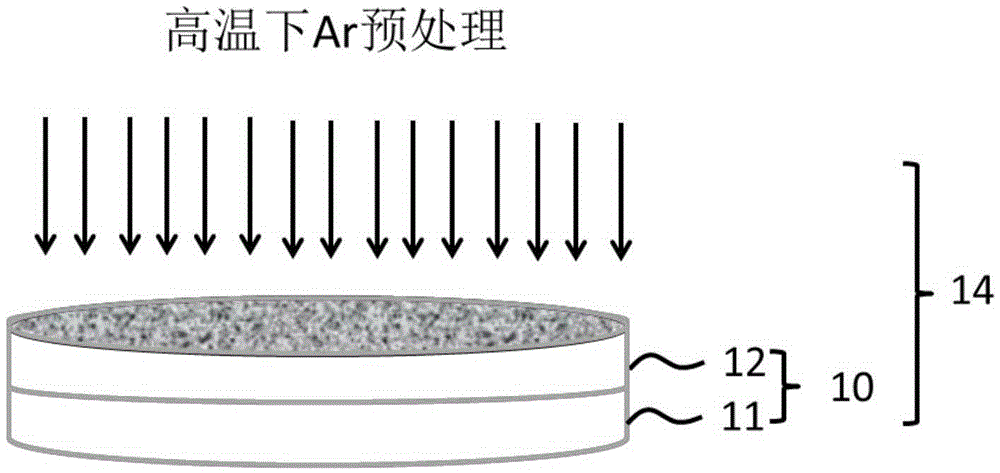

[0032] 1) Clean the silicon carbide material 10, the silicon carbide material 10 includes a substrate 11 and an epitaxial film 12, the substrate 11 in the silicon carbide material 10 is n-type 4H-SiC, the thickness is about 380 μm, n-type doped impurities Nitrogen (N), the doping concentration is about 5×10 18 cm -3 ; The epitaxial film 12 in the silicon carbide material 10 is n-type 4H-SiC with a thickness of about 12 μm, and the n-type doped impurity is nitrogen (N), and the doping concentration is about 8×10 15 cm -3 ;

[0033] The silicon carbide material 10 is cleaned by the RCA standard cleaning method, and the specific cleaning steps are as follows:

[0034] (1) Prepare hydrofluoric acid solution (HF:H 2 O=1:10);

[0035] (2) The sample holder is cleaned and dried for use;

[0036] (3) Take the silicon carbide sample 10 and put it on...

Example Embodiment

[0048] Example 2

[0049] A method for preparing an oxide film on a silicon carbide surface, the method comprising the steps of:

[0050]1) Clean the silicon carbide material 10, the silicon carbide material 10 includes a substrate 11 and an epitaxial film 12, the substrate 11 in the silicon carbide material 10 is n-type 4H-SiC, the thickness is about 300 μm, n-type doped impurities Nitrogen (N), the doping concentration is about 5×10 20 cm -3 ; The epitaxial film 12 in the silicon carbide material 10 is n-type 4H-SiC with a thickness of about 15 μm, and the n-type doped impurity is nitrogen (N), and the doping concentration is about 8×10 18 cm -3 ;

[0051] The silicon carbide material 10 is cleaned by the RCA standard cleaning method, and the specific cleaning steps are as follows:

[0052] (1) Prepare hydrofluoric acid solution (HF:H 2 O=1:10);

[0053] (2) The sample holder is cleaned and dried for use;

[0054] (3) Take the silicon carbide sample 10 and put it on ...

Example Embodiment

[0066] Example 3

[0067] A method for preparing an oxide film on a silicon carbide surface, the method comprising the steps of:

[0068] 1) Cleaning the silicon carbide material 10, the silicon carbide material 10 includes a substrate 11 and an epitaxial film 12, the substrate 11 in the silicon carbide material 10 is n-type 6H-SiC, the thickness is about 450 μm, n-type doped impurities Nitrogen (N), the doping concentration is about 5×10 18 cm -3 ; The epitaxial thin film 12 in the silicon carbide material 10 is n-type 6H-SiC, the thickness is about 15 μm, the n-type doping impurity is nitrogen (N), and the doping concentration is about 8×10 15 cm -3 ;

[0069] The silicon carbide material 10 is cleaned by the RCA standard cleaning method, and the specific cleaning steps are as follows:

[0070] (1) Prepare hydrofluoric acid solution (HF:H 2 O=1:10);

[0071] (2) The sample holder is cleaned and dried for use;

[0072] (3) Take the silicon carbide sample 10 and put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com