Method for preparing magnesium oxide whisker/ magnesium composite powder by in-situ growth on surface of magnesium powder

A magnesium oxide whisker and composite powder technology, which is applied in the field of ceramic whisker/metal composite powder materials, can solve the problems that cannot be prepared by growing magnesium-based composite materials, unfavorable large-scale production, high raw material costs, etc., and achieve continuity and combination Good performance, uniform size, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

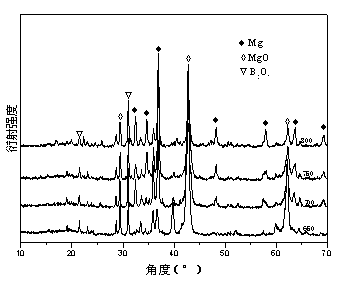

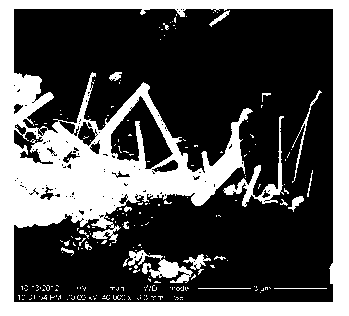

[0015] Place a 250 ml flask containing 10 g of boric acid powder in an ultrasonic oscillator at a water temperature of 30-50 °C, dissolve boric acid with 180 ml of absolute ethanol, add 10 g of magnesium powder, and stir at a constant temperature of 40 °C using a magnetic stirrer After 5 h, the samples were taken out and dried to obtain prefabricated mixed powder after the complete evaporation of absolute ethanol. Spread the prefabricated mixed powder in the quartz ark, and place the quartz ark in the constant temperature zone of the vacuum tube heating furnace. Firstly, protective argon gas is introduced into the tube furnace, and then the heating rate is increased to 650 °C for calcination at a rate of 5 °C / min, and the whisker is grown at a heat preservation rate of 2 hours. Magnesium whisker / magnesium composite powder product.

Embodiment 2

[0017] Place a 250 ml flask containing 10 g of boric acid powder in an ultrasonic oscillator at a water temperature of 30-50 °C, dissolve boric acid with 180 ml of absolute ethanol, add 15 g of magnesium powder, and stir for 4 hours at a constant temperature of 50 °C using a magnetic stirrer , after the complete evaporation of absolute ethanol, the sample was taken out and dried to obtain a prefabricated mixed powder. Spread the prefabricated mixed powder in the quartz ark, and place the quartz ark in the constant temperature zone in the middle of the vacuum tube furnace. First, protect the tube furnace with argon gas, and then raise the temperature to 700 °C at a rate of 10 °C / min. Calcination, heat preservation for 2 hours to grow whiskers, and naturally lower the furnace temperature to room temperature under the protection of argon to obtain a magnesium oxide whisker / magnesium composite powder product.

Embodiment 3

[0019] Place a 250 ml flask containing 10 g of boric acid powder in an ultrasonic oscillator with a water temperature of 30-50 °C, dissolve boric acid with 180 ml of absolute ethanol, add 20 g of magnesium powder, and stir at a constant temperature of 60 °C for 3 h using a magnetic stirrer , after the complete evaporation of absolute ethanol, the sample was taken out and dried to obtain a prefabricated mixed powder. Spread the prefabricated mixed powder in the quartz ark, place the quartz ark in the constant temperature zone in the middle of the vacuum tube furnace, first pass protective argon into the tube furnace, and then raise the temperature to 750 °C for calcination at a rate of 10 °C / min , heat preservation for 2 hours to grow whiskers, and the furnace temperature was naturally lowered to room temperature under the protection of argon to obtain a magnesium oxide whisker / magnesium composite powder product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com