One-step preparation of carbon nitride/titanium dioxide heterojunction photocatalyst by electrospinning

A titanium dioxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of poor photocatalytic performance, small specific surface area, complicated methods, etc., and achieve low cost and process. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

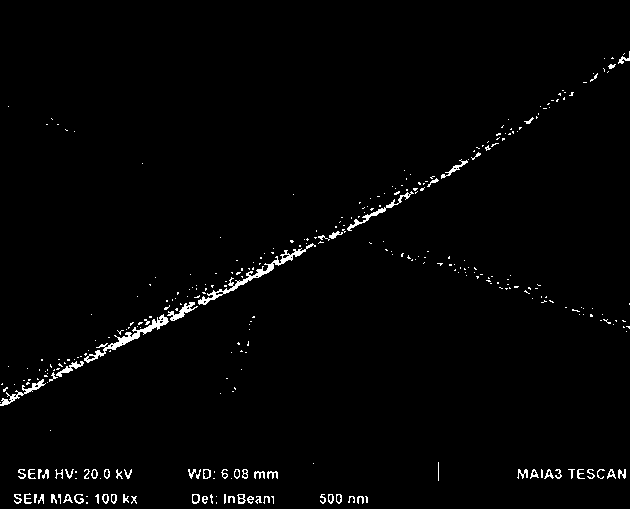

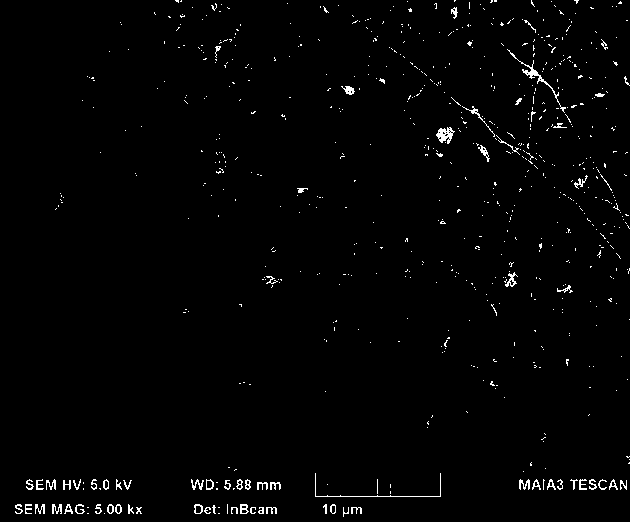

Embodiment 1

[0025] Grind 0.3g of melamine for 6min, add it to a conical flask, then add 8ml of methanol, ultrasonicate at 200w for 5min, then add 0.3ml of glacial acetic acid, 2ml of tetrabutyl titanate and 0.52g of polyvinylpyrrolidone, stir magnetically for 2h to obtain a uniform Spinning solution; the spinning solution is packed into a plastic syringe with a stainless steel needle for high-voltage electrospinning, the spinning voltage is 12kV; the distance between the needle tip and the receiving plate is 14cm; the air humidity is 40%; melamine / tetrabutyl titanate is obtained The ester / polyvinylpyrrolidone fiber membrane was transferred into a muffle furnace and calcined at 5°C / min and 520°C for 2h to obtain a carbon nitride / titanium dioxide heterojunction photocatalyst.

Embodiment 2

[0027] Grind 0.8 g of melamine for 7 minutes, add it to the Erlenmeyer flask, then add 9ml of methanol, ultrasonicate at 200w for 5 minutes, then add 0.4ml of glacial acetic acid, 2ml of tetrabutyl titanate and 0.6g of polyvinylpyrrolidone, stir magnetically for 2.5h to obtain a uniform Spinning solution; put the spinning solution into a plastic syringe with a stainless steel needle for high-voltage electrospinning, the spinning voltage is 14kV; the distance between the needle tip and the receiving plate is 14cm; the air humidity is 38%; The butyl ester / polyvinylpyrrolidone fiber membrane was transferred into a muffle furnace, and calcined at 4°C / min and 510°C for 2h to obtain a carbon nitride / titanium dioxide heterojunction photocatalyst.

Embodiment 3

[0029] Grind 0.6 g of guanidine hydrochloride for 5 min, add it to a conical flask, add 8 ml of methanol, ultrasonicate at 250w for 4 min, then add 0.3 ml of glacial acetic acid, 2.5 ml of tetrabutyl titanate and 0.8 g of polyvinylpyrrolidone, and stir magnetically for 2.5 h Obtain uniform spinning solution; The spinning solution is packed into a plastic syringe with a stainless steel needle to carry out high-voltage electrospinning, and the spinning voltage is 15kV; the distance between the needle tip and the receiving plate is 14cm; air humidity 35%; obtain guanidine hydrochloride / The tetrabutyl titanate / polyvinylpyrrolidone fiber membrane was transferred into a muffle furnace, and calcined at 5°C / min and 520°C for 2h to obtain a carbon nitride / titanium dioxide heterojunction photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com