Method for preparing carbon nanotube/magnesium composite powder by nickel catalytic in-situ chemical vapor deposition

A technology of chemical vapor deposition and carbon nanotubes, which is applied in the field of carbon nanotube/metal composite powder preparation, can solve problems such as no research reports, and achieve the effect of simple process, good dispersion and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

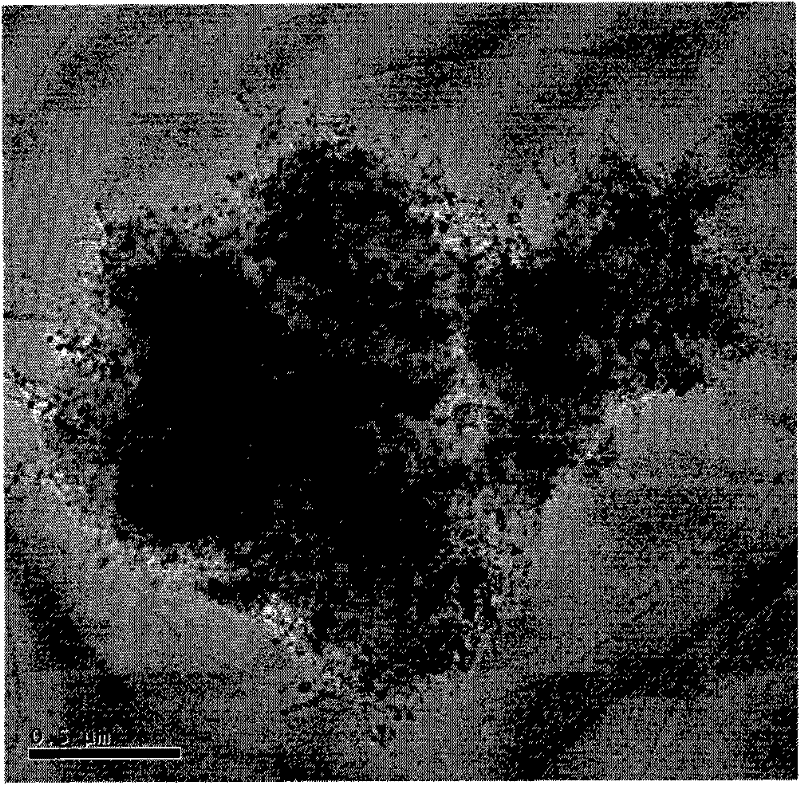

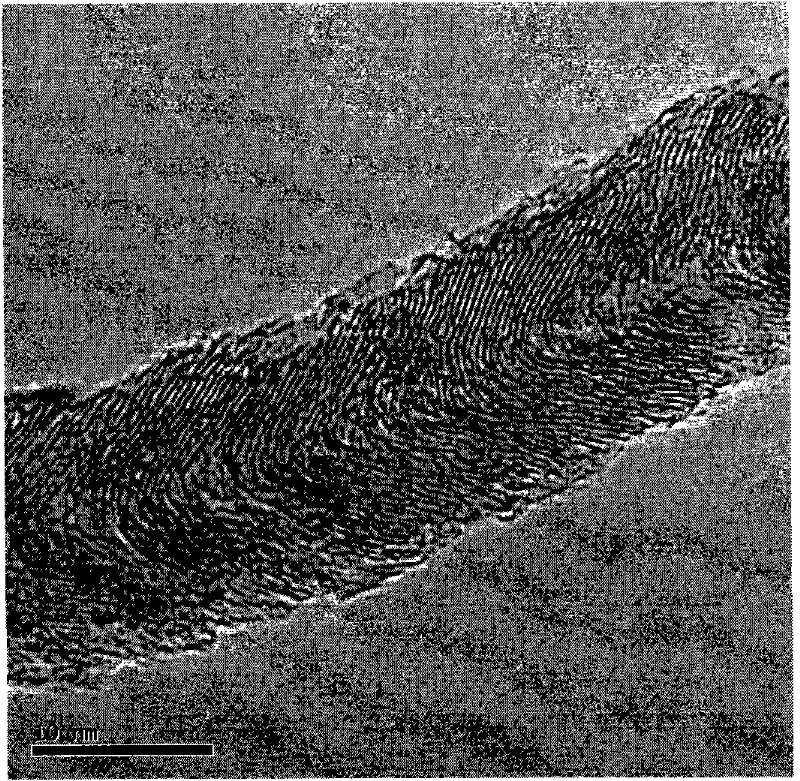

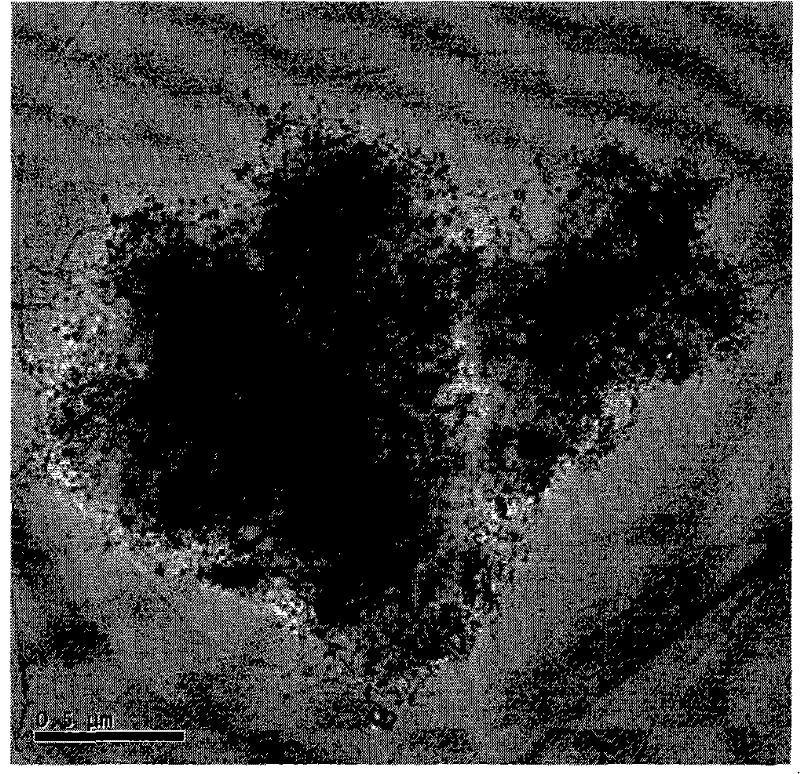

[0016] Add 5g of magnesium powder and 1.239g of nickel nitrate hexahydrate into 100mL of absolute ethanol, ultrasonically disperse with a power of 100W for 5 minutes, then magnetically stir at room temperature, and control the temperature at 65°C to slowly volatilize the absolute ethanol. until evaporated. Under the protection of argon, the obtained product was heated at 10°C / min to a temperature of 200°C, calcined for 4 hours, and cooled to room temperature with the furnace in an argon atmosphere to obtain a catalyst precursor with a mass ratio of nickel / magnesium of 0.05:1. Take 0.5g of nickel / magnesium catalyst precursor powder, spread evenly in the quartz boat, and place the quartz boat in the constant temperature zone in the middle of the quartz reaction tube. After ℃, feed hydrogen at 100mL / min, turn off the hydrogen after 2 hours, and raise the temperature to 500℃ at 10℃ / min under the protection of argon, then introduce methane as the carbon source gas, and then make th...

Embodiment 2

[0018] Add 5g of magnesium powder and 1.586g of nickel nitrate hexahydrate into 100mL of absolute ethanol, ultrasonically disperse with a power of 100W for 5 minutes, then magnetically stir at room temperature, and control the temperature at 65°C to slowly volatilize the absolute ethanol. until evaporated. Under the protection of argon, the obtained product was heated at 10 °C / min to a temperature of 400 °C, calcined for 2 h, and cooled to room temperature in an argon atmosphere with the furnace to obtain a catalyst precursor with a nickel / magnesium mass ratio of 0.08:1. Take 0.5g nickel / magnesium catalyst precursor powder, spread evenly in the quartz boat, and place the quartz boat in the constant temperature zone in the middle of the quartz reaction tube. After ℃, flow in hydrogen at 50mL / min, turn off the hydrogen after 4 hours, and raise the temperature to 550℃ at 10℃ / min under the protection of argon, then introduce methane as the carbon source gas, and then make the argo...

Embodiment 3

[0020] Add 5g of magnesium powder and 1.239g of nickel nitrate hexahydrate into 100mL of absolute ethanol, ultrasonically disperse with a power of 100W for 5 minutes, then magnetically stir at room temperature, and control the temperature at 65°C to slowly volatilize the absolute ethanol. until evaporated. Under the protection of argon, the obtained product was heated at 10°C / min to a temperature of 300°C, calcined for 3 hours, and cooled to room temperature in an argon atmosphere with the furnace to obtain a catalyst precursor with a mass ratio of nickel / magnesium of 0.05:1. Take 0.5g of nickel / magnesium catalyst precursor powder, spread evenly in the quartz boat, place the quartz boat in the constant temperature zone in the middle of the quartz reaction tube, first pass argon into the reaction tube, and raise it to 450 After ℃, flow in hydrogen gas at 200mL / min, turn off the hydrogen gas after 2 hours, and keep it warm at 450℃ under the protection of argon, then let in metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com