A double buffer layer lateral epitaxial growth method for improving LED brightness

A technology of lateral epitaxial growth and double buffer layers, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complex process, time-consuming samples, secondary pollution, etc., achieve simple process, reduce absorption, increase overall reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

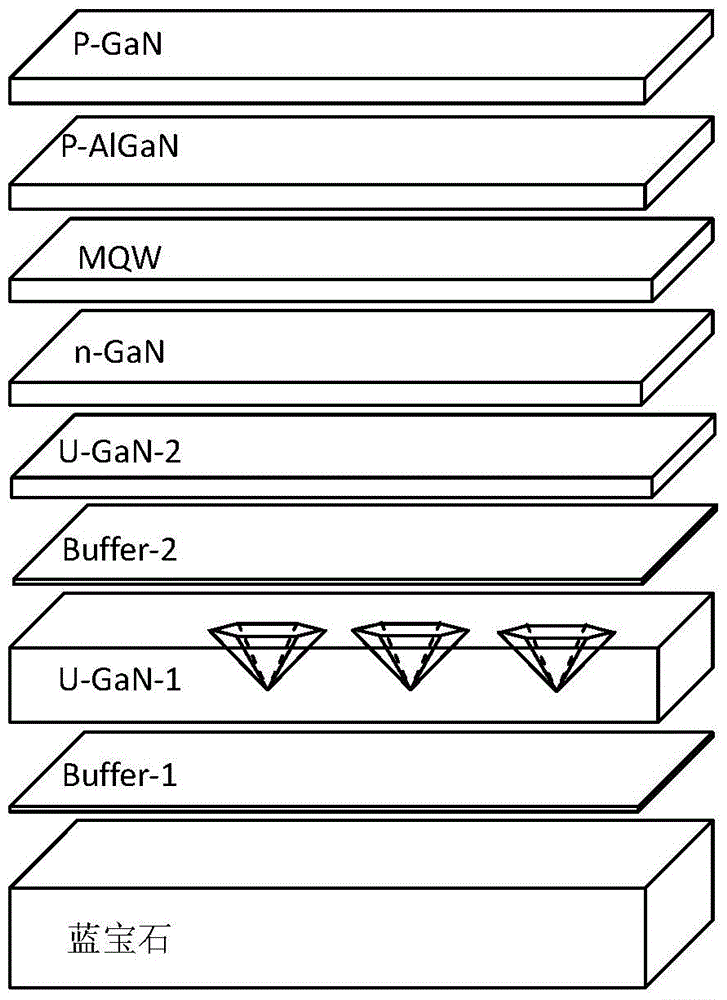

[0025] 1. Put the cleaned sapphire substrate into the MOCVD equipment and bake it at 1100°C for 10 minutes.

[0026] 2. A low-temperature buffer-1 layer with a thickness of 20nm is grown at a temperature of 520°C, and the growth pressure is 500torr.

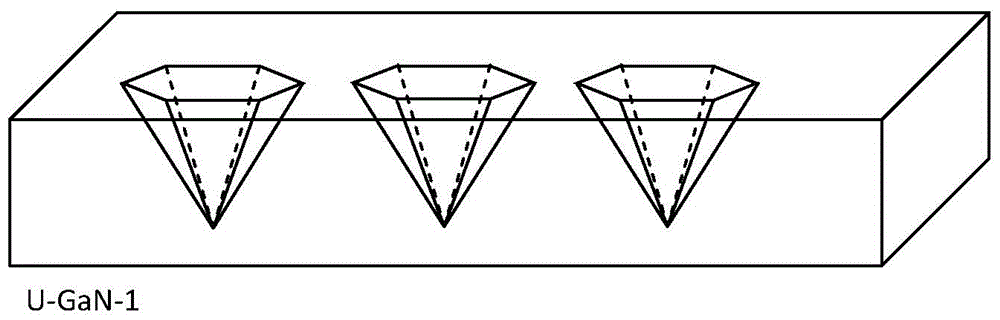

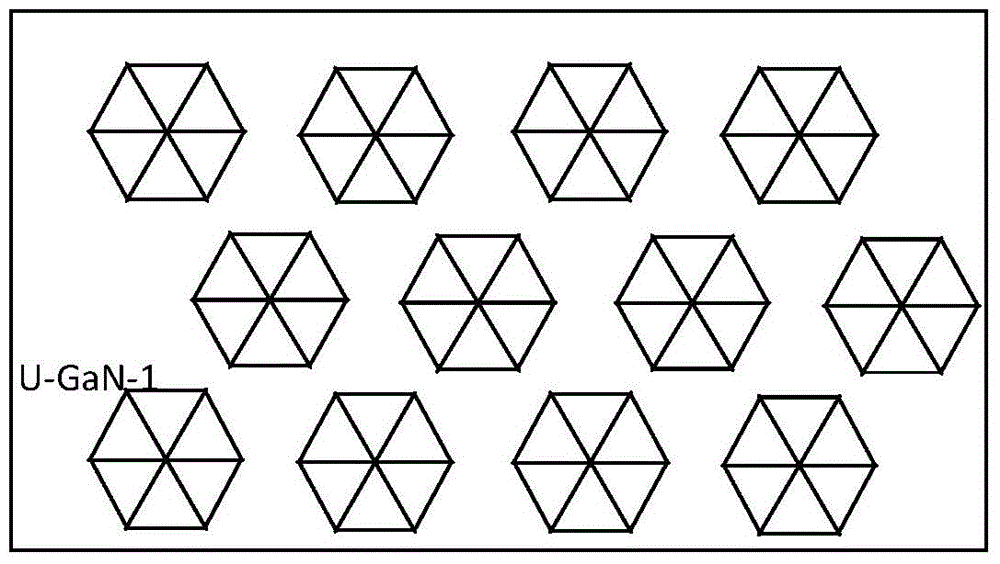

[0027] 3. Raise the temperature to 1050°C to grow a layer of undoped U-GaN-1 layer with a thickness of about 2.0um, and the growth pressure is 100torr.

[0028] 4. In the NH3 environment, raise the temperature to 1170°C, anneal for 5 minutes, and the pressure is 200torr.

[0029] 5. Lower the temperature to 650°C to grow a low-temperature buffer-2 layer with a thickness of 20nm and a growth pressure of 500torr.

[0030] 6. Then raise the temperature to 1160°C to grow a layer of undoped U-GaN-2 layer with a thickness of about 1.0um, and the growth pressure is 100torr.

[0031] 7. Raise the temperature to 1170°C, grow a layer of n-GaN doped with silane with a thickness of 2.0um, and grow at a growth pressure of 100torr.

[0032]...

Embodiment 2

[0038] 1. Put the cleaned sapphire substrate into the MOCVD equipment and bake it at 1100°C for 10 minutes.

[0039] 2. Lower the temperature to 650°C to grow a low-temperature buffer-2 layer with a thickness of 20nm and a growth pressure of 500torr.

[0040] 3. Then raise the temperature to 1160°C to grow a layer of undoped U-GaN-2 layer with a thickness of about 1.0um, and the growth pressure is 100torr.

[0041] 4. Raise the temperature to 1170° C., grow a layer of n-GaN doped with silane with a thickness of 2.0 um, and grow at a growth pressure of 100 torr.

[0042] 5. Switch the carrier gas from hydrogen to nitrogen at a pressure of 100 torr to grow multiple quantum well layers.

[0043] 6. Switch the carrier gas from nitrogen to hydrogen, and grow a p-type AlGaN layer with a thickness of 20nm and a growth pressure of 100torr at a temperature of 1185°C and 150torr.

[0044]7. The temperature is 1080°C, a layer of p-type GaN doped with Mg is grown with a thickness of 150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com