Water plant flow cross energy-saving system

A process system and water plant technology, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficulty in location arrangement, and save power consumption and infrastructure investment. , reduce the effect of management links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

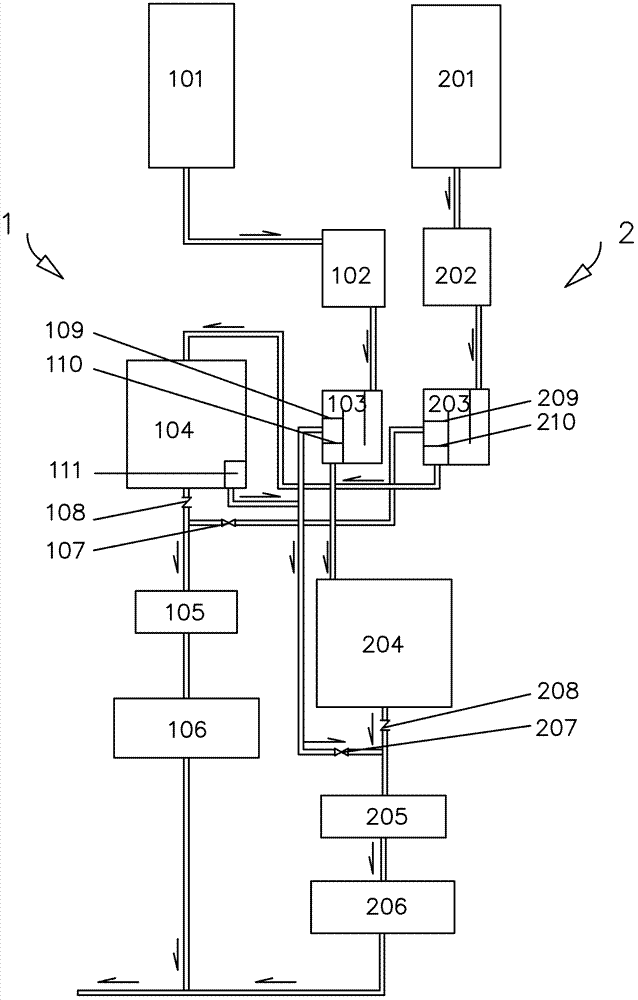

[0016] refer to figure 1 As shown, a waterworks process cross energy-saving system is mainly composed of the existing first-phase process system 1, the newly-built second-phase process system 2 and related pipelines and valves; the first-phase newly-built advanced treatment structure activated carbon adsorption filter 102 The newly built second-phase clear water pool is connected through relevant pipelines and valves, and the activated carbon adsorption filter 202 of the advanced treatment structure of the new second-phase process system is connected to the already-built first-phase clear water pool through relevant pipelines and valves, so that the already-built first-phase and the newly-built second-phase Process systems 1 and 2 intersect before the newly-built second-phase clear water pool or the first-phase clear water pool that has been built.

[0017] The process system 1 that has been built in the first phase mainly includes a conventional treatment structure 101 that h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com