Thick-thin-tex piled yarn as well as preparation method of thick-thin-tex piled yarn fabric

A ply yarn, thickness technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of poor fabric strength, limited product application range, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

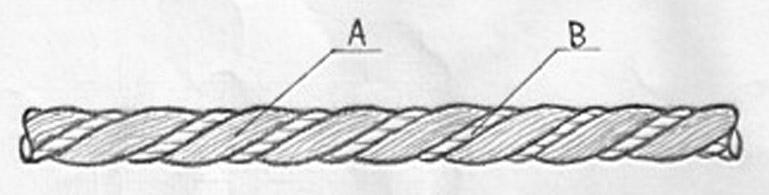

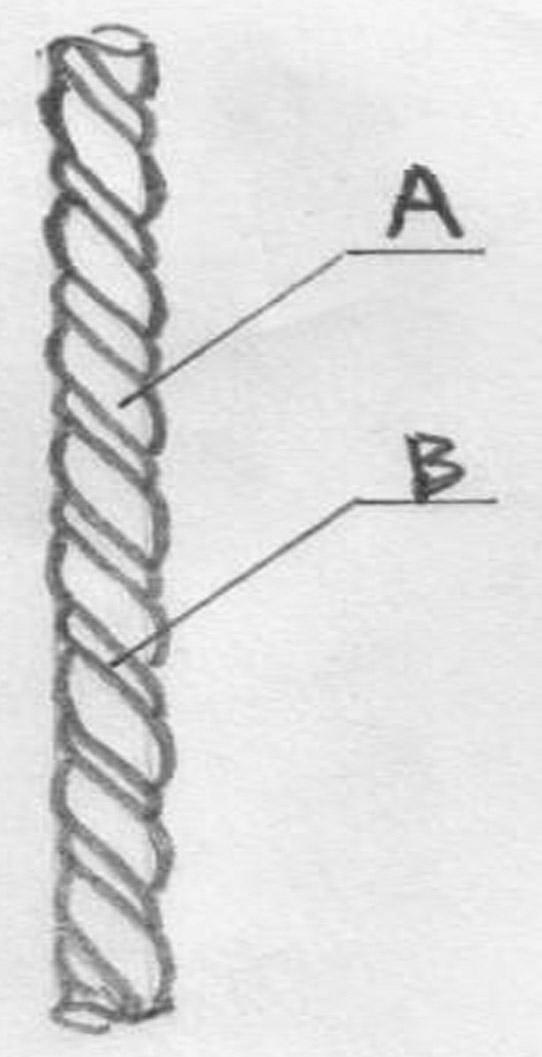

[0023] The invention relates to a thick and thin special ply yarn, which consists of two yarns with different tex numbers combined and reversely twisted, and twisted in a helical shape in the length direction, one of which is a thick special yarn A, the fibers on it are arranged parallel to each other; the other one is fine yarn B, and the fine yarn is twisted yarn or filament.

[0024] The coarse yarn A in the ply yarn has a twist coefficient range of 280 to 310 when spinning a single yarn before plying; the fine yarn B in the ply yarn, when spinning a single yarn before plying, The twist coefficient ranges from 285 to 320; the reverse twisted twist coefficient ranges from 280 to 310 when the coarse yarn A and fine yarn B are plyed.

[0025] The thickness of the roving yarn A ranges from 3 to 40 lbs, and the thickness of the roving yarn A is 2.8 to 3.5 times that of the matched fine yarn B.

[0026] The coarse yarn A is obtained by blending one or more combinations of pure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com