A kind of spandex supersoft clothing fabric and processing method thereof

A technology of spandex and clothing, applied in the field of spandex super-soft clothing fabrics and its processing, can solve the problems of easy skin damage, inferior moisture absorption and air permeability, and insufficient softness of synthetic fibers, and achieves easy operation, convenient and fast processing, and guaranteed hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

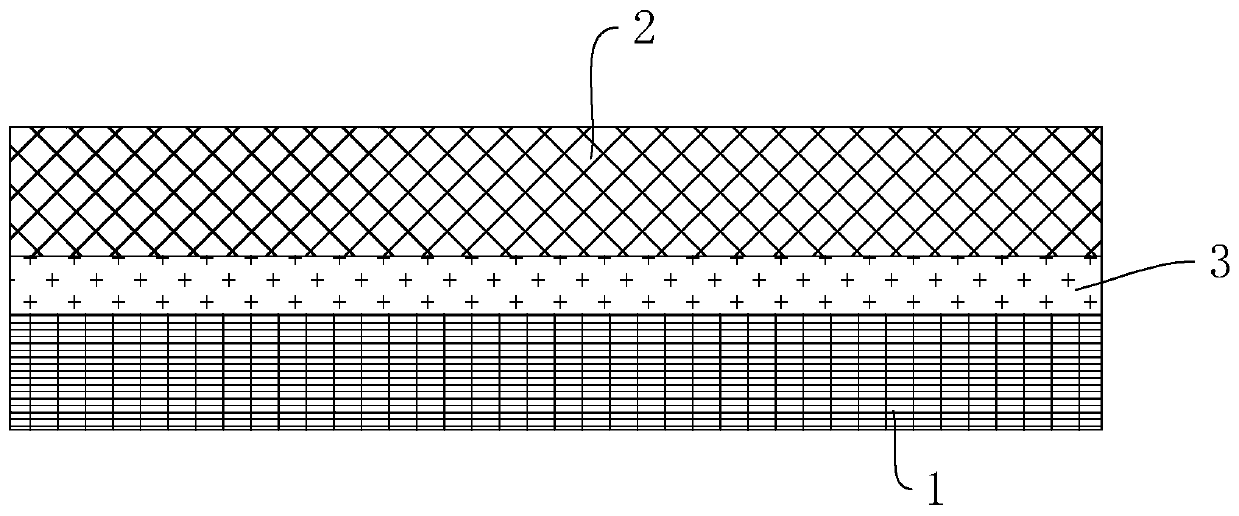

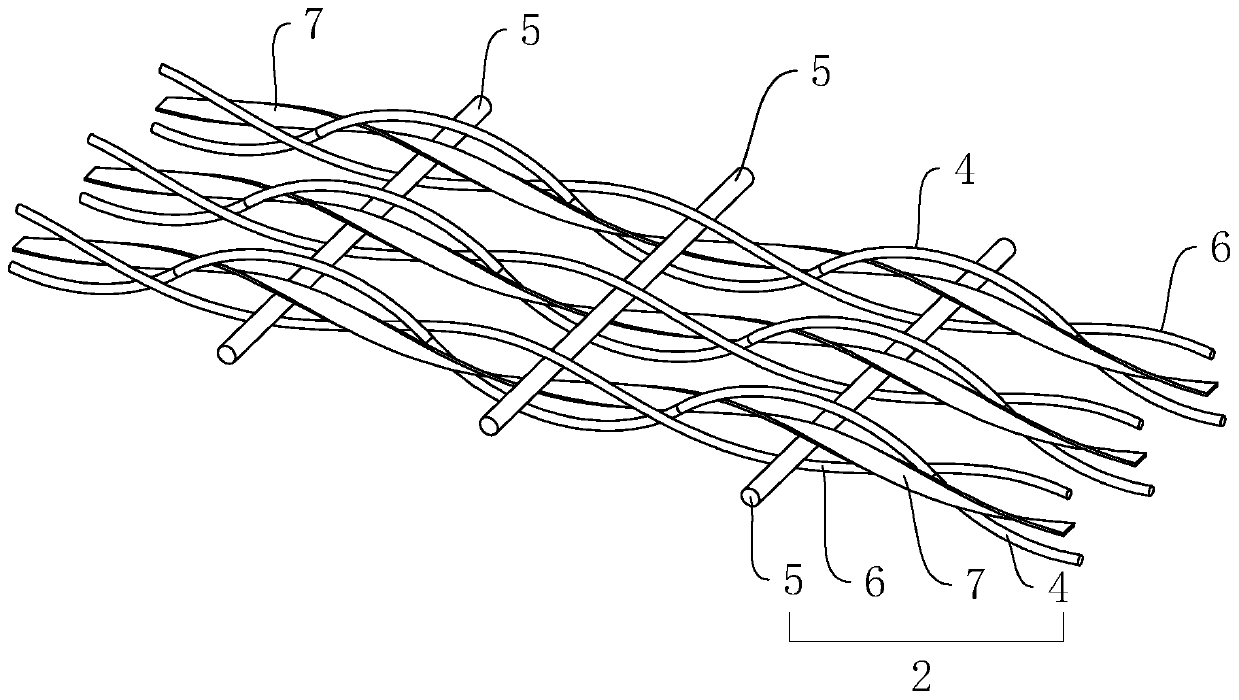

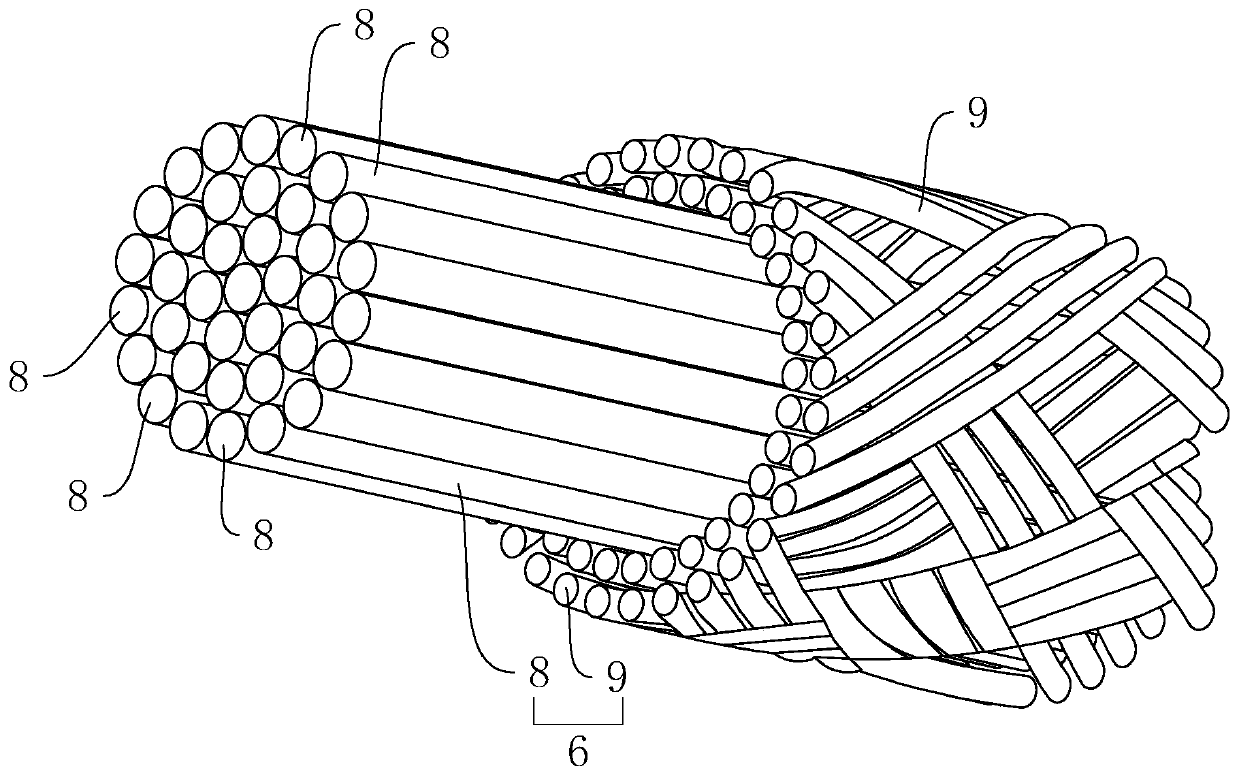

[0050] Embodiment 1: a kind of spandex supersoft clothing fabric, such as figure 1 As shown, it includes a cloth base layer 1 and a lining layer 2 attached to the side of the cloth base layer 1 close to the skin of the human body, wherein a layer of polyurethane adhesive layer 3 is arranged between the cloth base layer 1 and the lining layer 2, and the polyurethane adhesive The agent layer 3 is staggered distribution by the polyurethane adhesive through the glue dispenser. In addition figure 2 As shown, the inner material layer 2 includes FDY warp yarns 4, FDY weft yarns 5, and polyester core-spun yarns 6 that are threaded on the FDY weft yarns 5 and interlaced with the warp yarns to form a "eight" shape. Among them such as image 3 As shown, the polyester core-spun yarn 6 includes several spandex core yarns 8 and composite long fiber layers 9 woven around the spandex core yarns 8 . The composite long fiber layer 9 is composed of four long fibers in each group, which are wov...

Embodiment 2

[0053] Embodiment 2: a kind of spandex supersoft clothing fabric, the difference with embodiment 1 is: in order to promote the air permeability, hygroscopicity and softness of polyester core-spun yarn 6, above-mentioned composite long fiber layer 9 is nylon fiber filament and Polyester fiber filament. Among them, nylon fiber is also called polyamide fiber, which has good wear resistance, tensile strength, elastic recovery rate, fatigue resistance and hygroscopicity. Polyester fiber, also known as polyester fiber, is made from purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (EG) through esterification or transesterification and polycondensation reactions. The obtained fiber-forming high polymer - polyethylene terephthalate (PET), the fiber made by spinning and post-processing. It has high strength, good elasticity, good wear resistance and good corrosion resistance. Therefore, the use of the above two filament fibers can not only improve t...

Embodiment 3

[0054] Embodiment 3: a kind of spandex supersoft clothing fabric, the difference with embodiment 1 is: as Figure 4 As shown, in order to improve the overall bulkiness, hygroscopicity, elasticity and hand feeling of the fabric, the above-mentioned spandex super soft clothing fabric also includes flat 144F polyester yarn 7 which is sequentially threaded between the polyester core-spun yarn 6 and the FDY weft yarn 5 . Wherein, the flat 144F polyester yarn 7 refers to a flat yarn composed of 144 polyester fibers. Thus the flat 144F polyester yarn 7 itself has good rigidity, which can not only improve the connection strength between the fibers in the lining layer 2, but also utilize the gaps between the fibers to improve the overall bulkiness and moisture absorption of the fabric. Strength, elasticity and feel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com